Methods for cleaning the diesel filter by folk remedies. Flushing of the diesel engine filter with their own hands

In Europe, they are considered one of the most popular. BUT B. diesel engine, as in gasoline, fuel does not burn completely. As a result, various poisonous and additions are also formed in the exhaust gases, there are also soot in them, because the hydrocarbons are not completely burned. In Europe, in the 2000s, the fighters for the environment developed a standard for the level of harmful emissions into the environment. Automakers, in order for their products to be suitable for these standards, the particulate filter on the diesel should be installed. What it works and how it works, you need to know those who drive on diesels. Today we will try to answer all these questions.

Main functions

In order to better understand the purpose of these devices, it is necessary to touch the topic of exhaust gases. The automotive exhaust contains a mass of particularly toxic and carcinogenic substances.

Thus, carbon monoxide, unburned hydrocarbons, aldehydes, sulfur oxides, tetraethylsvinets have a very harmful effect on the environment. In addition, in the exhaust gases of a diesel car, in particular, heavy trucks, large quantities contain soot.

In order to reduce the concentration of this component, in the design modern car An oil filter was introduced on the diesel. What is this detail? This is something similar to the catalyst in the gasoline engine.

What does item look like

So, this device is intended to neutralize South - the product formed during the combustion process diesel fuel. There are two species - this is closed (DPF) and closed with the possibility of regeneration (FAP).

With all its simplicity, in fact, these auto parts for foreign cars have a rather complex device. Regardless of performance, the filter is a metal cylinder. It contains nozzles - input and output. The output is connected to the exhaust gas purification system.

The main element of the filter is a special matrix, which is made of silicon carbide.

It is concluded in a metal cylinder. The structure of this matrix is \u200b\u200bcelly. As for the cross section of the cells, it is often square. But more efficient cells having an octagonal form.

In addition, a diesel filter has several sensors in the design. This is a sensor that captures the pressure difference, and the sensor of the input and output temperature.

Principle of operation

The size of one soot particle is approximately 0.05 μm. By chemical composition, this product is nothing but ordinary carbon. To delay these particles using conventional tools is very difficult due to the size of the element. To capture South, it is necessary to use the diffusion principle. To understand what is a typical particulate filter on a diesel engine, which is the device, it is necessary to look inside it.

So, the filter inside is a ceramic matrix. This is a whole series of tubes, while the ends are closed. Inside this matrix, the exhaust gases come from the motor side, however, when the gases fall into the tubes, they simply cannot move on to move. Then through the walls of the tubes, they fall into the adjacent open cavities and can then get out of the matrix. In the process of diffusion, even the smallest particles remain inside the filter, which means it performs its task.

Where is the diesel filter

Find this item will not be difficult. The filter is often installed in exhaust system car.

Due to the design features, the part can be found between the silencer and the catalyst. In some cases, the device can be combined with the catalyst and is located directly at the exhaust manifold. There is a maximum temperature of gases, and such a filter has a catalytic coating.

Receptions

To effectively use on a diesel engine, the price of which is quite high (about 900 euros), it is necessary to properly operate the car. The thing is that in the process of cleaning the exhaust gases, the cells and tubes are clogged with soot. This leads to a decrease in performance diesel engine.

The filter bandwidth decreases and the resistance to the exhaust of waste gases increases. Many manufacturers in order to increase the service life of this stock without need frequent replacementThe special filter operation algorithm was applied when the fill level is controlled. If the filter is filled in so that the engine power is lost, the filter regeneration is started.

Causes of reducing efficiency

There are several reasons why filters are clogged. The main reason is the quality when the car is refueling by poor-quality fuel, a large amount of soot is formed - the filter is quickly clogged, which reduces its service life.

Another reason is insufficient temperature. So, the soot burns not completely.

The thing is that it is a diesel particulate filter. What is it? It not only delays particles, but also maintains the temperature for burning them. However, it should be said that this happens when the heating of the spent gases is high and is no less than 600 degrees Celsius. With smaller indicators, the soot will not burn.

Among the reasons for reducing the temperature of the gases also allocate several. These are motion modes, traffic jams, violation of the combustion process of fuel. Thus, the temperature in the system will not rise if the speed is low, and the movement is accompanied by frequent stops.

Monitoring status

In order to control the status of the Diesel engine path is equipped with control and measuring equipment. It includes temperature and pressure sensors. These elements form signals for the electronic control unit, and it determines whether the filter is filled or not yet. When the element is strongly filled, the cleaning process begins.

How to clean

In order to restore the efficiency of the engine when filled with a sump filter, it is enough to use several simple methodsthat will help run self-cleaning. Regeneration can be both passive and active type.

In any case, the process occurs through the combustion of the soot and the release of tubes and channels.

For the regeneration process, it can be used to increase the level of heating of exhaust gases, additives, or washing the sump filter. Additives will help reduce the temperature at which the soot will burn. A flushing with special substances will help clean the filter.

Passive regeneration method

Such cleaning can be carried out directly by car enthusiast. The need for regeneration will report the corresponding indicator. Also run this process is necessary if the dynamics or power of the engine decreases.

The most important thing is to increase the temperature for spent gases. This is done by movement by car with full load. It is enough to drive 30-40 km so that the filter is completely cleaned and the whole soot burned out. The second option is to use special fuel additives.

Active regeneration

This mode can be run by automatically controller. For this, the electronics analyzes information from the temperature sensor and pressure sensor. It informs the electronic control unit that the filter is scored, and the sensor reports the temperature. If it is not enough so that the soot is completely burned, the ECU may additionally inject fuel in the process of producing exhaust gases. This will burn soot in the exhaust. It also allows you to raise the temperature to the desired level.

If there are other equipment in the graduation path, which also increases the heating, the ECU can also use them.

Flushing

For this procedure, special fluids are needed.

The procedure itself as a whole depends only on the type of means.

So, the filter is removed and closed its holes. Then the cleaning fluid is then poured in such a way as to fill the entire filter volume. Next, the product must be left alone for ten o'clock, while to shake the filter from time to time. After that, the part is washed with warm water and installed back to the car. There are several types of liquids, and for each - your flushing method. It should be remembered before performing these procedures.

Flushing and cleaning will help extend the operation of the element, because the replacement of the scene filter is a very good pleasure.

But sooner or later, the term will come after all. It is recommended to change filters after 180 thousand kilometers.

The depreciation of this design affects primarily the conditions of movement, the quality of fuel, as well as the driving style. If the machine is experiencing significant loads, the replacement of this item may be required earlier.

So, we found out why this detail is served in the car. Dairy filter, like other auto parts for foreign cars, is an important detail of a modern car. This element improves the environmental situation in the world, and this is the health of people. High-quality ecology is a healthy society and happy children.

Magazine " BODY"Together with the company Liqui Moly. Tested a new product for cleaning and protecting the sump filters.

With the equipment of modern diesel cars Additional devices of exhaust gases (scenic dPF filters) There are problems in their work. The smaller the difference in the pressure of the exhaust gases at the input and output of the scene filter, the more efficient the engine works, the fuel is more economical and the environment is minimally contaminated.

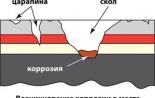

However, for all the time, solid soot particles, which are unlawful particles of hydrocarbons, fall into the pores of the walls of the particulate filter, limiting the flow exhaust gases. The fine particulate powder seems to be burned, however, as the filter clogs, it is increasingly mixed with non-aggravated materials and forms resins. This adhesive mixture is associated with metals sulphates, which are formed when combustion of poor quality motor oil, clogs the diesel filter, creating inside an increased backpressure of spent gases.

The particulate filter can almost completely score in just a few hundred kilometers of run, so the developers have provided a cunning system of its "regeneration" - a process that oats the resins inside the filter, after which their burnout occurs. When the gas pressure at the input and output of the DPF exceeds the permissible standard, the engine control unit turns on the burden mode.

The computer enriches fuel mixture, as a result, the temperature of the exhaust gases increases sharply. The load on the catalyst increases, and it, in turn, heats up to several hundred degrees, oxidizing the pair of unburned fuel. After that, a hot filter comes to the particulate filter, which burns out the deposits and cleans the filter. The same process can be initiated by a chemical way - by adding a special additive activating the burner. At one time, the Volkswagen concern applied this technology, and today the constructors of Peugeot and Citroen are passionate about such developments.

Car different marks The burden mode is included with quite standard conditions. For this, the car must be in motion, and the engine work on medium or high revolutions. In the dense city traffic of suitable conditions, it is not always possible, so the filter continues to delay the soot without self-cleaning, which leads to its complete closure.

Ideally, the life of the particulate filter is 150,000-200,000 kilometers, and self-degeneration occurs only once every 500-700 kilometers. However, in the urban stream, this item comes into disrepair much earlier. Long traffic on traffic jams, low-quality fuel, elevated temperature ambient And the aggressive driving style leads to the fact that the process of burning in the filter starts every 50-100 kilometers, which reduces the life of the unit to 50,000-80,000 kilometers. This is explained by the fact that with each regeneration, together with petroleum products, part of platinum from the catalyst will burn out, which significantly affects its residual resource.

In addition, to effectively burn all the resins from the cavities, you need to heat the catalyst up to 600-650 ° C, which is practically unrealistic during the trip. As the soot accumulate inside the system, the difference in the pressure of gases at the inlet to the filter and at the output of it once exceeds the permissible indicators. As a result, when the diesel filter is contaminated by more than 90%, the engine is simply loss of power and stalls.

With the appearance of dashboard The car of the corresponding problem is necessary to urgently turn to the service station. Experienced diagnostics will check the system and give a conclusion. Often, manufacturers do not regulate the repair of contaminated diesel filters, offering only a complete replacement of the part. Thus, systematically poured into its car a poor-quality Russian diesel fuel, the car owner knowingly "signs" on permanent and expensive repairs. Only the cost of the Supil filters themselves top brands exceeds 100,000 rubles.

Of course, on the quality of fuel, the car owner is unable to influence, but it may take care of the preservation of the filter. To do this, Liqui Moly has developed a cleaning and protection program for the sump filters, which includes two fundamentally different cleaning technologies and a special additive to facilitate the filter regeneration.

The first technology allows you to work literally "on the knee" and do not use deficient and expensive diagnostic devices. However, it is a time consuming, requires enough time and implies the removal of the particulate filter. The second technology is faster, but requires the use of complex electronic equipment. As for the results, there is, the effectiveness of the compositions of the products, they are identical. According to Liqui Moly specialists, the cost of this service will not exceed 10,000-15,000 rubles, which is significantly cheaper full replacement filter.

The editors of the magazine "Body" decided to check on their own new system And to demonstrate to readers her work. For this, the edition correspondents chose an independent STR specializing in mercedes-Benz carswhere Dmitry Rudakov, Liqui Moly SpecialistThey offered to show and prove the efficiency of the system on the Mercedes ML model of the third generation.

The complexity of work S. mercedes models It is caused by both the inaccessibility of the same size filter itself and the characteristics of the diagnosis. For example, when checking cars concern Volkswagen. The filter state is displayed on the diagnostic scanner screen. percentage ratiothat significantly simplifies the decision-making process. Mercedes, on the contrary, only indicates a malfunction, indicating the discrepancies in ideal and real values. Thus, the master must determine the nature of the upcoming repair.

For work, specialist Dmitry Rudakov will first need a cleaner Liqui Moly Pro-Line Diesel Partikel Filter Reiniger and washing / neutralizer Pro-Line Diesel Partikel Filter Spulung.

Cleaning solution must be pouring into a special tank, on which a gun with one of the attached probes is attached. Direct and curved manipulators allow you to work with almost all manufactured cars.

It is necessary to make sure that the temperature of the particulate filter is about 40 ° C, since it is precisely in such conditions that effectively explicitly. Temperature can be seen on the screen diagnostic equipmentHowever, if it does not turn out to be at hand, it is enough to measure the heating of the filter with an optical domestic pyrometer.

In the next one can remove the oxygen sensor, located in front of the particle filter, through which the cleaning liquid will be served. However, in our case, the specialist did not do this, because it is convenient to use another hole on Mercedes. The representative of Liqui Moly removed the catalyst temperature sensor, which is located in the middle of the filter, between the catalyst and the active DPF element. Accessing the cleaning fluid through this hole ensures the correct distribution of the fluid in all cavities.

After test spray, the cleaning composition is fed through the above hole inside the filter for several receptions. During this process, the probe needs to rotate slowly, thereby providing a uniform distribution of the means.

Now you need to wait 15 minutes and in the same way pour inside the wash / neutralizer. After completing cleaning, put the temperature sensor.

To evapose the residues from the filter, you need to start the engine and warm the filter to operating temperature at 300 ° C. After that, using the diagnostic scanner, you need to start the forced regeneration mode. Next within 10-20 minutes you should drive 10 kilometers by car.

If there is no opportunity to leave a hundred, you will have to simply press the gas pedal throughout the same time interval, but it is necessary to do it either on the street or with a connected exhaust gas removal system. Literally after a couple of minutes of engine operation under load exhaust pipe Think thick white smoke. This suggests that the procedure is carried out correctly.

The diagnostic scanner will also help determine how well the filter cleared. To do this, it suffices to check the readings of the exhaust gas pressure sensors at the inlet and outlet of the particulate filter in the percentage ratio before and after the procedure. Also, the effectiveness of the solution can be judged by temperature values.

In our case, the verification of reliability has shown that the temperature of the catalyst in 190 ° C is almost equal to the temperature inside the scene filter - 180 ° C. According to the standards, these readings should not differ by more than 60 ° C.

According to Liqui Moly's calculations, the cost of cleaning the particulate filter can vary within 10,000-15,000 rubles. This amount includes payment of labor, consumables And self-sufficiency of equipment, the price of which is 15,000 rubles. However, it is significantly cheaper than a complete disassembly of a spoiled smbed filter, buying a new filter and its subsequent installation.

According to Dmitry, on business-class cars, it is advisable to carry out the procedure for cleaning the particulate filter together with the oil change and cleaning of the injector, it is desirable to include it in the list of regulatory work every 10,000-20,000 kilometers. On the budget cars It should be done only as needed when an appropriate error appears.

As we have already spoken, the service life of the particulate filter is determined by the frequency of its burns. The more often this procedure occurs, the more catalyst (platinum) flashes irretrievably. Today it became possible to increase the runs between the burns and reduce the process temperature. To do this, Liqui Moly has developed a additive to protect the Diesel Partikel Filter Schutz Diesel Partikel Filter Schutz, which we will describe in detail in a separate material.

The car lost the power, badly start, and you suspect that everything is a diesel particulate filter? Flushing the particulate filter is one way to solve your problem, as well as a wonderful preventive procedure that allows you to extend the service life of expensive parts.

Every day, more stringent requirements for emissions are presented. harmful substances in atmosphere. To meet the established environmental standards (Euro 4, Euro 5), cars are equipped special filters, Colding soot and burning it in safe mode.

According to manufacturers, the resource of the particulate filter is enough for the entire service life of the machine. You do not need to conduct specially maintenance or replacement parts. But why then need a flushing of the diesel engine filter?

The reasons why the diesel filter is clogged?

Unfortunately, not everything is so rosy. Russian fuel "became famous for" low quality. In addition to sulfur, it may contain dirt, various resins. If you also refuel on dubious gas stations, you can get a low-quality surrogate, diluted with octane-insiding additives. When combustion of such fuel, resins are formed, which not only settled on the walls of the combustion chamber, but also fall into the diesel filter, where the powdered soot glue. As a result, the filter is gradually clogged and cannot pass exhaust gases, which leads to a drop in engine power.

Manufacturers provide that when the difference in the pressure at the input and output of the scene filter will reach a certain threshold, the burden mode is started. But here there are nuances. The mode is activated only while driving and only with high (or medium) revolutions. Moving around the city, the machine is more simple, which means the filter cannot be cleaned timely. Gradually, pollution goes for controlled limits and at one fine moment the car simply does not start. Even if it is possible to start the engine and accelerate to the required speed, burns with nothing help. Too late…

Flushing of the diesel engine filter

You can replace the particulate filter to the new one. But the item will have to be ordered directly from the manufacturer, and this is time. The price of replacement comes up to 100 thousand rubles and more. The second option is to remove the filter and reflash the computer. But no one gives warranty that the new firmware will work. Sooner or later, you will have to pay a penalty for environmental pollution.

We offer the best decision - rinse filter. Special flushing from the company Liqui Moly. Dissolves accumulated resins. After cleaning, the diesel filter is fully cleaned, all its characteristics are 100% restored.

Immediately warn you, trust the washing of the particulate filter only by professionals. The procedure is carried out with the help of specialized and sufficiently expensive equipment. With the deviation from the technology there is a risk even more to score the filter, then it will have to change it. In addition, the cleaning agent is very aggressive and in the skin gets on the skin provokes strong burns, or it may be deprived of sight, hitting the eye.

Flushing the size filter Price

How to extend the life of the diesel filter?

IN russian conditions There is an opportunity to extend the life of the diesel filter. Just once, 2,000 kilometers add a special additive to fuel - Disel PartikelFilter Schutz, and refuel only on proven gas stations.

Do not forget to regularly visit the car service engine on Warsaw - this is a guarantee that your car is always all right.

At the end of the last century, Environmentalists began to fight the owners of automotive companies and oil towers, accusing them in excessive pollution of the environment. To somehow calmly calm the indignation of fighters for the clean atmosphere, the designers have developed such a detail as the diesel filter. With the beginning of its use in the automotive industry, we stopped breathing soot, which stands out during the combustion.

What is this unit, what is his appointment

The particulate filter is used in the design of diesel engines. It allows you to thoroughly clean the exhaust from various unwanted impurities, as it has a fine structure of the cell. This item makes the environment a little better.

Despite all its utility, the diesel filter has one significant drawback - the need. The fact is that it is spontaneously cleaned only when driving at high speed, which is not always possible for the car enthusiast. Experts are recommended after every 150 km passed cars on the highway.

However, even when performing this Council, the replacement of the particulate filter is inevitable. It is not fully cleaned, and its high degree of contamination can lead to the following undesirable consequences:

- reducing power diesel engine and increased fuel consumption;

- overheating of the motor in the hot season;

- reducing the motor resource, which leads to its breakdown.

Clean the filter element

If the particulate filter is not polluted, that is, you have timely identified the initial stage of the filtering element contamination, then you can be cleaned. This process will improve, and therefore solve problems with insufficient motor power.

On video - cleaning the particulate filter:

Cleaning the particulate filter is carried out by automotors on each self-respecting service. Here, pollution in the early stages will be removed quickly and inexpensively. If you wish to save on the services of professionals, you can always clean the device personally.

This item, like beeshu, consists of a large number of small holes, which over time clog soot, sage and other product combustion products of diesel fuel. To clean it use a special additive, which is added and mixed with diesel. During trips on such a fuel, the filter element is cleared.

There is a second option. It is assumed to remove it for cleaning the filter. After that, the part is soaked in a special chemical agent and is blown under the action high pressure. After such a washing, the item is installed on its former place.

As you see, adding additives to fuel avoids the downtime of the car and therefore is a more diesel engine filter.

Cleaning did not help - go to replace

If your car's sump filter is in a deplorable state, then the only way out is to save the ecology and not losing in the power of the motor - it is replaced by a new one. In this case, you do not pay so much for the work as for a new item.

The new filter element is worth a lot of money, especially if we are talking about original details. The replacement of the particulate filter itself is to remove the old and. Motorists conduct similar manipulations quite rarely, again, because of high cost Details itself.

Down from the engine!

Another solution to the contaminated particulate filter is to remove it. It will reduce fuel consumption, do not ride from time to time large turns For the regeneration of this part, to increase the power of the car and forever get rid of the risk of a motor breakage due to clogging.

An independent shutdown of the scene filter consists of two stages. On the first you make it physical removal, and on the second - software.

At the first stage you will need to cut the compartment with this element and catalyst. In their place you can install a plane sensor or simply weld a piece of pipe. The installation of the planeencitel will increase the durability of the muffler and exhaust system, engine power and change the sound of the exhaust to the lower.

On video - removal of the particulate filter:

In the second stage, in order not to occur in errors in electronic block Motor control, in a welded piece of pipe, it is necessary to breed the temperature sensors and the lambda probe. After getting rid of the scene filter, you will need to spend. This procedure will first allow you to get rid of the emissions of gray-black smoke.

After removing the filter detail, your engine will not be so capricious in service. It is also worth noting that you will immediately lose.

The particulate filter allows you to save the environment from harmful fuels, soot and smoke exhaust. If you are contaminated, you will be before choosing from three options: it is replaced, cleaning or shutdown. Each of these options have its pros and cons. Having decided, remember that your children and grandchildren will live on this planet.

Soot in the engine occurs as a by-product combustion of fuel. Although its volume depends on the ratio of air and fuel, it is still formed in one or another quantity. Bringing the pollution of the environment by it helps a diesel filter that delays about 97% of all particles in itself. He does not give her to go out, and in the future it is simply burned when the engine is working. Such an effect of burning and is called regeneration.

The device of the particulate filter and the principle of its action

The scene filter has a simple device based on a cellular membrane. It is made of silicon carbide and is a variety of small channels connected by jumpers. The use of such a design and material ensures the following characteristics filter:

Due to this, it is able to fulfill its task for a long time, intercepting miniature particles of soot on the path of exhaust.

The principle of operation of such a device is no different from an ordinary filter. Say particles simply remain in the membrane system without going out. Since all spent gases are passed through this filter, the system is able to block a substantial part of the soot in the exhaust process.

But it is important to remember that the filter is constantly filled with soot particles, which leads to a reduction in bandwidth. To eliminate them, regeneration is carried out, which is provided for by the structure itself.

Signs of clogging of the particulate filter

When the car is working, it is important to maintain the bandwidth of the filtering system. Therefore, sensors defining this parameter and, if possible burning soot in the element, are often built into the system. The problem is that burning is possible only with long-term ride at high speed, therefore it does not turn on when driving for short and winding distance.

For this reason, riding within the city does not give a chance to regeneration. The burning occurs in the minimum degree, while maintaining most of the zoom in the system.

Tip! Poor fuel quality also contributes to an increase in the amount of soot. If the motorist saves on it, then it is necessary to diagnose the filter zoom.

Therefore, it is important to control the state of the system and follow the possible symptoms of the sampling filter:

- increase fuel consumption;

- reduction of thrust;

- stable high level oils;

- non-medical work system;

- smoky exhaust;

- it is possible to hiss when driving.

And the main feature that is worth paying attention is the filter icon on the dashboard. If she caught fire, it is necessary to urgently go to the diagnosis.

Riding a scored filter is contraindicated for any car. With an abundant amount of particulate precipitation, a breakdown of various elements is possible in the system. Oil clogs, which leads to a decrease in engine performance. Over time, the gas recycling system is destroyed, and in the future the engine itself breaks.

Regeneration of the diesel filter

The principle of regeneration is simple: microparticles, scoring the membrane, are burned at a temperature of more than 500 ° C. Therefore, the cleaning process is to raise the temperature in the system to such a mark so that the exhaust gases can burn pollution. This is possible only with the full load of the engine.

There are two types of membranes that differ in location: FAP and DPF. The first type is located on the removal from the engine, and the exhaust gases cannot sufficiently heat the particles. Therefore, for such a task, the fuel additive is used.

Since the exhaust gases pass a big way from the engine to the cleaning element, they simply cannot burn blockage. Temperatures are not enough for such a task, so it is necessary to increase it. For this, special ceriable additives are applied. Ceria microgranules allow you to warm up the gases to the required plank, thereby destroying the blockage.

The additive itself is a cerium microgranules in a special substance. This form allows you to save your structure before entering the filter. Initially, the gases will only evaporate the shell of the granules, freeing the cesium. When he falls on a heated membrane, it is sharply flammable, raising the temperature of the surrounding gases to 1000 ° C. Such a bar is safe for the system, because the heating occurs locally.

Interesting! Although such a temperature can destroy the ceramic lattice, the duration of heating is minimal. This makes this method safe for the system.

The second type of filters is located near the engine, so necessary level Temperatures are achieved without additional tools. The spent gases almost immediately fall into the filter, thereby burning the blockage and continuing its path.

Such a cleaning procedure occurs only in full speed, so it is important to periodically squeeze the engine on full power. But it is worth remembering that the regeneration does not need to be carried out daily, the frequency depends only on the intensity of soot formation.

Forced regeneration and cleaning manually

If the filter was used in adverse conditions, thereby clogging, then use it is prohibited. He simply destroy the system and the engine, which will turn into overhaul. Therefore, with full blocks, it is necessary to undergo a procedure for forced regeneration.

Forced regeneration can be launched with special equipment, often present in service centers. It allows you to quickly eliminate the zoom by connecting the cleaning system. However, it is not always possible to enable it. In cases where the filter is filled above the norm, the cleaning system will not be turned on.

If this happened, the washing will help here with special means. Often it allows you to eliminate most of the soot, after which it is possible to connect regeneration.

Flushing is carried out by two methods:

- without removing the element;

- full flushing with removal.

In the first case, you need to take a spray gun and a flexible tube, as well as a filter cleaning agent. Tunap MP 131 is suitable for such tasks. The pressure source is also needed - compressor. Access to the filter is carried out through a pre-removed temperature sensor or pressure. It is necessary to thoroughly clean this element, approximate consumption per cleaning - to a liter of liquid.

Next, it is necessary to eliminate the liquid with the Tunap MP 132 concentrate. After that, the cleaning procedure is complete, you need to return the sensor to the place and regenerate the filter by regular methods. If the procedure does not help, it is necessary to carry out a complete flushing with the removal of the item.

The second method is to complete the filter and flushing it. First you need to remove the filter from the system and open it. Next it must be washed through special means like DPF Cleaner. They eliminate the remains of soot and oil, as a result of which those easily eliminate under water pressure. Such cleansing agents are washed off with water. Cleaning can be supplemented with special cleaning agents like Pro-Tec Dpfcatalyst Cleaner. However, it depends on the situation.

Tip! The use of the compressor can increase the filter cleaning efficiency. It is enough just to push the cleaner with pressure of compressed air.

After completion of the procedure, you need to dry the filter and install in the car. Then it is worth checking its condition and run regular regeneration. But it is worth considering that not always washing capable of helping against blockages. If available methods did not help, you will have to acquire a replacement.

Important! When using flushing means you need to wear gloves. It is important to remember that these are aggressive substances capable of harming the skin.

Replacing the filter is recommended for passing 180 thousand kilometers. This point can be pulled out by cleaning and regeneration, but the eternally this element cannot serve as the use of a clogged or poor filter will result in a sage in the system, which will definitely fall out in high repair costs.

And for a better understanding of the effectiveness of the washing of the particulate filters, it is recommended to see this video. Cleaning segment clogged filter Using the LUFFE tool. The stages of the procedure and the effectiveness of such washing are clearly shown: