How to restore old wiper brushes. Repair of the mechanism of wipers

Among motorists are not for nothing in vain the wipers are called janitor. In the process of its work, they provide cleanliness and good visibility for the driver, which adequately perceives the events on the road during the movement. Clean glass allows the motorist not to strain their eyesight to see the road through a dirty glass. Car windscitches are constantly responsible for any weather and at any speed.

In the summer and autumn, the wipers are constantly necessary. They come to the rescue in the snowfall and in the blizzard. Photo: autozhodino.by.

Winter has its own impact on wiper. Details from rubber on janitors are hardening, and on them is formed, which is not only poorly cleaning the glass, but also scratches it.

How profitable is the restoration of janits

Motorists with experience know many ways to reanimate old wipers. These methods, as a rule, do not require capital investments and take 10-15 minutes of time. Basically in poor performance, the rubber part of the janitors is to blame, which is responsible for the removal of dirt and moisture from the glass surface. Cheaper will try to restore it than changing completely wipers.

It is important to restore before the rubber component of the wipers crackle or break.

After proper processing, the elasticity of the gum will return to the janitor, and they will again serve a long time to motorists.

Folk ways to restore

Consider the most popular and effective ways to reanimate wipers on the vehicle and increase the service life:

- White Spirit. This solution effectively removes dirt, and fat with a rubber part of janitor. White Spirit is a rather popular solvent based on gasoline. Oil liquid additionally lubricates, which makes it easier to slide brushes over windshield. The processing process will not require special skills. It is necessary to take a wet moistened in a solution or a silica with a silica and wipe the rubber part of the janitors. Then give to dry and check the performance of the brushes. If necessary, the procedure can be repeated.

Restoration of the wipers glycerin

Let us consider in more detail the way to restore the wipers Glycerin:

- It is necessary to make dismantling of wipers from the vehicle and disconnect their rubber part.

- Clear from dirt and stuffed dust. Next you need to give dry brushes.

- After drying, the gum is treated with glycerin, and give them to lie down in order for the solution to be absorbed. The process of impregnation can be repeated several times and not forget to give the solution to absorb.

- After several procedures, you need to wipe the surface of the rubber and remove all the remnants from it.

- Then it is necessary to collect the wiper and consolidate by car. Conduct performance.

After this procedure, the rubber becomes softer. Efficiency during the work of the janitors increases. But this method will not help if the rubber has already cracked or broke out. This procedure is considered the most effective way to restore janitors.

Special devices for sharpening wipers

Principle of operation of the device for trimming janitors:

In the process of daily exploitation, wipers are obliged to cope with any weather conditions, friction about the surface of glass, dust and insect residues. After a while, the thin edges of the gum of janitors wear out, as a result of which stripes and divorces appear on the glass. therefore it is necessary to change wipers every six months, depending on the frequency of using the car.

Ecocut Pro reserve removes the poor-quality part of the wiper rubber and returns to it the previous form. The cost of the device is about 1000 rubles.

Advantages:

- safe and environmentally friendly technology;

- the ability to store in the car and does not take up much space;

- low cost and alternative to acquiring new janitors;

- it is possible to use for all types of brushes;

- fast and simple application directly on the vehicle;

- the ability to conduct a restoration procedure without removing them from the car;

- eliminates divorces on the surface of glass and unpleasant violin;

- increases the safety of the vehicle management, as the glass visibility increases.

With this cutter, the service life of old janitors is increased by 2 times. It is possible to conduct a restoration procedure 2 times, cutting the edge of spoiled rubber each time. After cutting the spent layer of rubber, the new layer begins to rub like a new one. If we take into account the cost of new windshield wipers, this device will save the means of car enthusiast.

Approximate resource of the Ecocut Pro cutter is 10-11 sections.

The option of restoring janitors can be found in this video:

Summary

The brutators brush will serve much more if they are competently used during operation. They also need care, as is the car as a whole. But the wiper failure is not a sentence. Available recovery procedures will help extend the service life. Also on the duration of the service is influenced by the manufacturer of janitors. It is necessary to acquire only proven and well-known brands and in the future do not forget to care for them.

Operation of the machine in conditions of poor visibility is what vehicle drivers face constantly. Depending on weather conditions (snow, rain, etc.) Overview of the space in front of the windshield of the car can deteriorate significantly, which contributes to the creation of an emergency on the road. At the same time, the purity of the windshield, which is provided by the windshield wipers of the machine, in everyday life of the wipers, has an important meaning and largely depends on the state of the latter.

Causes of poor quality windows

Having found that when working janitors, layouts remain on the windshield of the machine, it is necessary to check their condition and determine the causes of poor quality cleaner.

Quite often the reason for the appearance of divorces on the windshield of the machine is:

- ground windshield, which will not be able to clear the best windshield wipers;

- loose fit of elastic brushes to the windshield;

- malfunctions of metal parts of the windscreen wipers;

- wear of the cleaning edge of the elastic element of the brushes.

The reasons that caused the poor-quality work of the wipers may be due to:

- long-term contact of fixed brushes with windshield machines (deformation of elastic parts) under the influence of direct sunlight or with a strong frost;

- hitting the mud into the grooves of the elastic tape of wipers;

- in the grooves of water brushes with its subsequent freezing;

- a change in the chemical structure of elastic parts under the action of ultraviolet radiation (direct solar rays);

- wear of the working edge of the elastic tape;

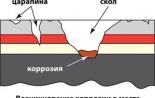

- the appearance of corrosion trash tape on the blades.

Restoration of janitor

Noticing that the brushes began to purify the windshield to the windshield, car enthusiasts, as a rule, try to replace them with new ones. However, this is not always justified, since in some cases Restore the performance of janitors on the car is not a lot of work. For example, if during the operation of the machine, it was found that the working edge of the brushes is strongly worn, it can be restored using sandpaper.

For this:

- Take a sheet of negligent material (multi-layer plywood, a fairly thick sheet of metal, etc.).

- Printed a strip of fine-grained emery paper on it.

- Conducting the cleaning blade of the janitor on the sandpaper, restore the ribbon form, giving the working edge a rectangular shape.

Important! It is necessary to closely ensure that the restored work surface of the wiper across the entire length of the tape turned out to be uniform. The presence of failures on it will lead to the fact that during operation on the windshield, the machine will remain wide uncleaned bands.

If the elastic tape of the janitor has hardened, then gasoline can be used to restore it. Having dippeding the tape into gasoline, it was then washed in warm water and applied a thin layer of silicone lubrication on the working surface. These procedures will be returned to the tape elasticity and make it softer.

Tip! Using silicone lubricant, you can also restore the performance of janitors for a short time, in which there are minor cracks on the work surface, causing scraping or creak during operation.

The working surface of the janitor was covered with an oily film, it is possible to restore its properties (degreased), for example, Using White Spirit. White spirit will easily remove fat and other contaminants from the surface of the brush. After this procedure, it is desirable to apply a thin layer of silicone lubricant onto the working surface of the glass wipers. Thus, it will be restored. How to restore the wipers by car Experienced motorists can be seen on:

In the same way, you can remove from the working surface of the wiper and corrosion traces.

Attention! When working with White Spirit, it is necessary to comply with the elementary safety regulations (ventilated room, gloves, etc.).

Care for windshields

Automotive wipers, like other components of the machine, require regular maintenance. In order to extend the "life" to the branches on the car, experts recommend:

- regularly clean the windshield of the machine and the working surfaces of the wipers from dust, dirt and fat deposits, and in the winter season from snow and ice;

- shoot the wipers if the car remains on the street for a long time;

- leaving the car in the garage, lift the wipers in such a way as to eliminate the contact of the elastic surfaces with the windshield (the distance to the windshield should be at least 5 mm);

It is extremely important in the winter time of the year to turn on the wiper only after the ice on the windshield car melts.

Service center "Rembyttech" replaces the brushes on the engines of washing machines in Moscow and the region. Call our workshop and call a specialist at home. Choose a convenient date and time, or wait for the wizard within 24 hours from the date of application. We carry out the replacement service at home on the machine-machine of any type (with frontal and vertical download) and year of release. To work and details issue warranty coupon, it acts 12 months.

How much does it cost to change the brushes in a washing machine

The cost of replacing the brushes - from 1400 rubles. Details are paid separately or the master sets the brushes purchased by the client. The full amount of payment expert counts after the diagnosis of the machine. The price depends on the model, type, brand "automat" and year of release.

The service includes:

- disassembling the car;

- engine removal;

- removal and inspection of old brushes;

- installing new contact elements;

- verification of engine operation;

- machine assembly and testing

Attention! Coal brushes belong to consumables, it is impossible to repair them, you can only replace.

The cost of replacing the brushes on washing machines of different marks See in the table

| Brand washing machine | Cost * (only for work, without item) |

| Is free | |

| from 1800 rubles. | |

| from 1500 rubles. | |

| from 1800 rubles. | |

| from 1900 rubles. | |

| from 1500 rubles. | |

| from 1700 rubles. | |

| from 1800 rubles. | |

| from 2100 rubles. | |

| from 2800 rubles. | |

| from 1900 rubles. | |

| from 1900 rubles. | |

| from 2100 rubles. | |

| from 1800 rubles. | |

| from 2100 rubles. | |

| from 1900 rubles. | |

| from 1800 rubles. | |

| from 2200 rubles. | |

| from 1900 rubles. | |

| from 1400 rubles. |

* Attention!The table shows only the price of replacement work. If the wizard installs parts from its stock, then additionally includes their cost in the full amount of payment.

How to call Masters

To call a specialist, call the Rembytteh service from 8 to 22 hours by phone:

Or leave an application through online forms w.on the site (around the clock). The service center works daily. The masters come on weekdays, on weekends and during the holidays.

When calling a specialist, inform:

- Mark brand and model. The model name is indicated on the equipment housing. Read it on the sticker and name the dispatcher, for example, Bosch Maxx 5 or Indesit WIU80. The information is needed to select the brushes. If you bought the items yourself, then just name the machine brand.

- Convenient time and date of repair.

- Contact details. Your name, phone and address.

The master will call on the appointed day and will confirm the time of visit.

Our advantages

- Consult 2 free.We explain the problem with the technique through the "Question-Answer" rubric. Describe a malfunction in your own words and send a message. Repair specialist answers a question for up to 2 days. When making an application, we consult on the phone. Tell the dispatcher what you want to talk to the master. He will call you back and tell you about the possible breakage and cost of repair.

- We travel for free and diagnose the technique at home.You pay only for the replacement of details and new brushes.

- We repair at home 24 hours after the application.We are located throughout the city and in most areas of the region. The master comes to the address from the nearest branch. Therefore, we can have on the same day if the application is filed in the morning. Or the next day, with an evening application. If you have chosen another date and time, the specialist will arrive at the designated time. We repair everything at home, without export to the workshop.

- We work daily from 8 to 22. Permanent schedule - every day, without weekends and holidays. Come early in the morning and late in the evening, convenient for those who work. Choose a wizard's visit time at your discretion.

- We guarantee repair quality for 1 year.We are responsible for work and replaced brushes. We issue a guarantee for 1 year. If the repair is installed when the client is purchased, the warranty is issued only to the wizard.

The main function of the brushes in the washing machine, and why they can not be repaired

Coal brushes is an element that provides the rotation of the collector engine. They transmit voltage between its parts. Without them there is no "communication" between the fixed stator and the movable rotor. With a weak contact between the brushes and the collector, the motor loses power, tweaked or stops.

In the process of operation, the brush rubs about the engine manifold and over time so shortening that they lose contact with it. That is why they are believed to consumables, and the stumps are replaced by new brushes.

The procedure for carrying out work when replacing the brushes by the "Rembyttech" master

What we do by completing the service of the client's house:

1. Disassemble the washing machine

The engine, most often, is located down the right side, if you look at the car from the back of the back wall. To get to the engine, the wizard removes the rear panel. In some styralls, before this, you need to remove the top cover.

Disassembly order:

- Fully de-energize the machine, pulling the plug from the outlet.

- Remove the back wall. We unscrew the screws of the screwdriver mounting (if the wall is additionally pressed up with the top cover, first remove it).

Remove the drive belt, which will go on the pulleys of the drum and the engine. To do this, we turn the pulley of the drum and slightly pull the belt to yourself.

2. Remove the engine and check the brushes

In most models, the Motor "will" on special holders and is fixed with screws or bolts. The sequence of our actions is such.

- Turn off the engine power cable. To do this, pull out the connector from the nest.

- We unscrew the fastener and take out the engine.

After the removal, the wizard checks that the brushes were embarrassed and, indeed, it's time to change. As a rule, it is easy to determine, visually looking at them. In Rembyttech, experienced masters work, who in appearance understand how critical wear from the brushes.

In some old models, the washing machines of the brush can be hidden behind the engine housing. In this case, the wizard checks them using a multimeter.

Note! Sometimes the stilt motor fastening design allows you to call brushes without removing the engine.

3. Change brothers

The brushes are inserted into special holders. The contact part comes into contact with the rotor collector, wired connected to the stator. In very old agents of "age" machines, access to graphite bricks is closed part of the motor. Therefore, it is necessary to partially disassemble it. But it is rare and usually the replacement procedure is as follows:

- Turn off the wires and make disassembly of wear brushes. For this, depending on the design, either reflect the pressure plate and pull out the brush, or we unscrew the holder with a brush with a screwdriver, disassemble it, we bite the wire of the coal of the brush from the holder after which the corner itself is removed. During dismantling, I will definitely remember where the contact part of the brush was sent. This is necessary for the proper installation of the new part.

- We inspect the collector. If it is strongly polluted, wipe it from dust.

- We install a new part in the reverse dismantling order. If the design is such that during dismantling the brush coal wire cut off from the holder, then new brushes need to be soldered. After installation, the wizard visually evaluates how electrical stacks are set: the end of the holder must act about 10mm. Also, the wizard checks the correctness and density of the adjuncting of the brushes to the collector.

- Connect the wires.

Note! In the design where it is necessary to get a new brush to the holder when replacing, often the master saves time and install a ready-made set of holder with a brushing solder into it.

4. We put the engine

Now we return the motor into the washing machine.

- We put on the electric motor to the fasteners and tighten the bolts or screws. Check the stability of the motor so that there are no moves and rooting.

- We put on the drive belt, first on the motor, then on the pulley of the tank. Check the tension, otherwise the belt flies when the engine is started.

- We connect the power, insert the loop into the socket.

5. Collect the car

We put the back panel and fasten it. The latter is put on top cover if it was also shot. After the assembly, run the washer in test mode to test the operation of the engine with a different load.

Attention! Even with the correct installation of the brushes, they pass "wreck" with a collector during 2-3 styers after replacement. Therefore, the washing machine can slightly noise and some spoke to the first time.

The main signs when it is necessary to change the brushes

The exact answer is that the brushes time to change, gives the machine diagnosis. But it is convenient to call the masters for the inspection. According to the repair experience, Rembyttech service engineers have prepared a list of features that can signal the need to replace electrical accesses.

- Problems with the rotation of the drum.The drum barely spins, and the machine can not gain momentum on annealing. Or the washer does not rotate the drum at all, immediately merging the water after the set. Either, it happens that the drum slightly twists at the beginning of washing, after which the machine stops washing and gives an error.

- Unstable engine work. With full load on the washing or when annealing, the machine loses turns.

- The noise and sparkling of the brushes. It is noticeable by the smell of metal or burning insulation, also in the dark shows the glow at the bottom of the washer, as from Bengal lights.

The described features can be completed by the interruption of the program and the display of the error code. The code is displayed on the display (if it is) or indicators flash. Most frequently, the brush wear signals the motor error, the duct or spin.

Causes of brush failure

Electrokers "refuse" due to marriage, physical wear (i.e. abrasion) or subflinking.

- Marriage. This production flames and it is rare.

- Wear coal brushes. The most common cause of replacement. The average service life of electric boards is 5-7 years. If you rarely wash and do not overload the machine, then the contact elements can be served and 10-12 years. After that, the length of the brushes reaches a minimum of 1 cm, and they cease to touch the motor collector.

- Sweeping. Sometimes brushed wear is not critical, but they lose contact with the collector. This is due to the fact that they are subdined in the holder. The brushes are pressed to the engine collector using springs that squeeze them from the brief holder. Coal dust is in the space between the brush and the holder, which is formed in large quantities as a result of friction of the brush of the collector. She stops her extrusion from the holder. Such a problem is called the "twisting of the brushes".

Note! In the case of subflinking, the brush wear may not yet reach the minimum permissible value, and the clutch is closing in the holder to restore its contact with the collector. But, in most cases, the wedge arises either when 3-5 mm remained to critical length, or when the brush geometry is broken. In both cases, it is advisable to change the brushes to new ones. If this is not done, the problem will repeat in the very near future.

To replace brushes in a washing machine, special knowledge and experience are required. Independent work often turns into additional difficulties with which it is difficult to understand without vocational training. The main difficulties calls:

- Motor disassembly of an old model. They cannot change the brushes without removing the part of the structure. And collecting the engine back, non-specialists often configure the connection of wires. As a result, the engine burns and has to change it completely.

- Proper brush installation. The item must be put in the right side (cut to the collector) and check the distance. If the contact element is fixed incorrectly, it will weakly touch the surface of the collector. As a consequence, the motor will not be able to work at full power due to weak contact and may even burn. And the machine will make noise and sell a long time. It is also dangerous and can cause fire.

- Soldering contacts. In some brands of washing machines, the brushes need to be soldered to the holders. It requires knowledge of soldering technology.

- Engine adjustment for belt tension. In the repair work related to the removal of the motor, during the reverse installation in place its position must be adjusted to provide sufficient belt tension. Otherwise, the belt will jump from pulley during the operation of the washing machine.

To avoid unnecessary problems with the washing machine when self replacing the brushes - contact "Rembytte". Review the wizards by phone:

Wait expert 24 hours after calling or on the selected day.

Wiper (janitor) in the car - This is an electromechanical device with a rubber brush, which serves to remove water and dirt from the windshield.

Invented a wiper in 1903 English Engineer James Henry Apjohn. And only in 1916 wiper began to install in mass production cars.

When the first signs of bad work of the janitor appears, in the form of a strip on the windshield of the car or insufficient transparency of the glass in the form of a thick water film after the passage of the wipers, many motorists replace brushes with new ones, not even trying to figure out the poor work of janitors. More economical motorists do not fit rinse the rubber ribbon brushes with soapy water and clean the surface of the glass from the dirt. Often it helps, but if the brush is already worn, then flushing and wipes do not help, even if there is an effect from such prevention, then for a short time.

Device and principle of operation of a frame brush of the janitor

If the metal or rubber frame of the janitor does not have serious mechanical damage, then such a brush can be repaired with their own hands. To fully repair the repair, the device and the principle of operation of the wipers of the car wiper should be.

Device frame brush

The main part of any car janitor is a rubber tape, since the purity of the windshield of the car in bad weather depends on its quality and technical condition.

Rubber tape for effective water removal is made quite elastic and two elastic plate springs are used to fasten it in the janitor. The plates in length are equal to the length of the rubber ribbon and are inserted from the two sides to the grooves specifically provided for this.

At the ends of the elastic plates, rectangular samples are made, and at the base of the tape are the same in the form of a protrusion. Thus, fixation of plates in rubber ribbon, excluding their movement, is ensured.

The brush frame is a few rocker uninunted interconnected with axes. The number of rocker depends on the length of the brush and there are them in the frame from three to seven pieces. The axes are fixed in rivet ribs.

For better mobility, plastic liners are inserted between them, which reduce the wear of the rockers and exclude the creaking when working as a janitor. In the middle of the longest rocker, the axis is pressed for fastening the plastic adapter for it - latches.

Adapters are needed for the possibility of installing the brush of the janitor on the leash (lever) of the wiper of any car model. Usually, new brushes are equipped with a set of the most demanded adapters suitable for almost any car windscitus. To fix the adapter on the rocker, it is enough to dress it on the axis and with an effort to press it on it. The adapter securely fixes on the rocker. Before installing the new adapter, you need to determine which of the set is suitable for your wiper. You can use the old adapter, removing it with the native brush that has spent its resource.

The length of the rubber ribbon depends on the size of the brush of the janitor. But the profile of tapes for janitors of different lengths and structures, including frameless brushes, is almost the same. True, there are ribbons that have additional sharp edges on the side surface, but this is already excluding, I have not seen them on sale.

On the photo of the profile, the tape is clearly visible three symmetric grooves passing along its entire length. The upper groove is designed to be installed in its elastic spring plates, which give the rubber tape elasticity and shape. In the middle grooves, the foot clips of the risk clamps are coming, including and fixing. The lower groove forms a neck of the tape and provides the possibility of shifting the working part of the rubber ribbon while changing the direction of movement of the janitor during the cleaning of the car windshield from precipitation and dirt.

Device frameless brush

Frameless brushes of janitors are rarely applied and due to their high cost and narrow use. Each brush is manufactured for a certain narrow range of car models. They are not universal.

Frameless brushes differ from the framework that instead of the rocker system, a flat wide spring-loaded metal plate is used, on which brackets of the janitor's tape holders are fixed with rivets.

The shape of the forming plate is made according to the form of windshield of a particular car. Therefore, they are not suitable for any model. This wide tape is closed with a rubber casing glued to it, making cases of disruption of the joints of the hinges, like a skeleton brush. The design of the rubber ribbon and the principle of its work when cleaning the glass does not differ from work in a frame janitor. In the frameless janitors, there is also an opportunity when wearing to replace the rubber tape, as in the skew janitor.

Principle of operation of the brush of the janitor

Removes water from the surface of the windshield of the car's brush brush thanks to the special form of the working part of the rubber ribbon. The photo of the ribbon is recorded in the photo when the brush is moving the brush from Lev to the right, in the direction of the blue arrows.

As can be seen, the working sheet of rubber tape is slightly flawed in such a way that its direct angle is perpendicular to the glass plane. Thus, a wide part of the ribbon cannon removes a thick layer of water. The remaining thin film of water, pushing it to the glass, removes the straight ribbon angle.

When changing the direction of the brush, the working part of the rubber ribbon of the brush of the janitor is shifted and already pushes a thin layer of water another straight corner of the tape. Thus, the janitor's brush carries out the windshield of the vehicle with direct and reverse course. The remaining water remnants after the passage of the brush in the form of a micron film due to scratches on the glass and entering small mechanical particles quickly evaporate and glass becomes transparent.

If during the work of the janitor working part of the ribbon or part of it takes the position relative to the surface of the cleaned glass, differing from the photographs shown in the photographs, then the car glass will remain opaque or water stripes will remain.

Causes of poor car windshield cleaning

Now knowing the device of the janitor and the principle of operation of the rubber ribbon, it will be easy to figure it out independently why the brush has become badly cleaning the windshield from the water and try to restore it before buying a new one. The poor job of the janitor is manifested in the form of the remaining bands after the passage of the brush or opaque, the turbidity of the glass, which makes the driver who impede the driver overview during the ride.

The first thing is necessary with the unsatisfactory work of the janitor to do, it is removed from the surface of automotive glass dirt, oil film and check the frame of the janitor. The mobility of the rocker in the places of their additions and the absence of breaking, the reliability of fixing the adapter and the wiper lever in it, the adequacy of the effort created by the spring clips of the wiper lever. In winter, water is often in the articulation of the rocker, water freezes, freezes and their mobility is lost. If the frame is in order, the brush audit should be conducted.

On the windshield of the car

After the passage of the janitor remains stripes

The brush leaves the strip of water on the glass due to the incorrect adjacent of a separate area, or several, working part of the rubber ribbon to the glass surface at the level of the left bands. At the same time, the strips of the brush can be left only directly, only on the opposite or at both directions of the brush movement. Strips may remain in the middle of the passage of the brush or along the edges. Causes, depending on the place of leaving the brushes, the strips are different.

The brush began to leave the stripes on the glass suddenly

If the janitor worked normally and suddenly began to appear the bands when moving into one of the sides, then the mechanical particles in the form of sand or dirt came in the groove of the rubber ribbon, which do not give the working part of the tape to bend, and the edge of a direct angle does not become perpendicular to glass. In winter frost, it is possible to get into the groove of water and its subsequent freezing. It is enough to remove the dirt out of the edge, and the brush will earn normally. The ice can melting itself from the heat of the windshield, heated by warm air blowing from the inside of the cabin, or the ice is necessary from the groove of the tape gently so as not to damage tightly tapes, remove the sharp item.

If the strips suddenly began to appear in the middle when the brush of the janitor is moving in both directions, it is possible that the ingress of dirt and ice in the grooves of the tape from both sides and the loss of the ribbon from the retaining flat spring plates. This happens in winter. If the brush approached the windshield and it was pulled off, pulling away from the glass for the rocker, without waiting when the glass warms up, the ice melts and the brush is free.

As can be seen in the photo, the plate came out of the rubber ribbon rubber, and the ribbon lost linearity. Therefore, it is unacceptable to dypipe about the brush for the rocker, if there is no time to wait, then you need to gently move the ribbon along the glass with a scraper. This malfunction of the brush is not difficult to eliminate even without removing it from the car. You must first put in the groove the elastic plate on one side of the rubber ribbon, and then the screwdriver blade to start the plate in the groove on the other side.

Stripes on the windshield after the passage of the brush

Expanded gradually

If a narrow strip appeared when the janitor first appeared, and then for a long time - days, weeks gradually expanded, it means that the cause of the malfunction is most likely due to the wear of the rubber belt of the brush. As a result of aging in places of bending, rubber ribbons, usually cervices, cracks appear, and rubber in these places rushes, more often on the edges of the brush. The tape continues to break and the zone of the bands increases.

The photo shows a brush with a torn rubber ribbon along the cervix line from the unfinished end. Such a ribbon recovery is not subject to and should be replaced with a new one. If the non-torn part of the rubber ribbon clears the glass is still good and the brush tape broke from the unfinished end, then it can be reused by setting a shorter brush to the frame.

With a serviceable ribbon, the bands can still appear when the brush moves, slowly expanding, with the wear of one or more hinge connections among themselves. Then the tape, when changing the movement of the janitor, it is not always shifted, and the water remains on the glass. In this case, the brush, when moving, can jump over the glass.

When the wipers are not included, the brushes under the action of the spring of the wiper leash are pressed with a rubber ribbon to the glass. At the same time, the tape along the neck is bent. From the effects of temperature with time, the rubber is deformed, which leads to the inability to take the ribbon the working position when the janitor is turned on.

The photo is clearly visible deformation of the rubber ribbon, the working part was deformed on the left side. With the onset of greater deformation, although the working angles are not yet worn, the tape will not be able to shift and fully purify the glass from the water.

Another enemy of automotive brushes is time. Even if the brush almost did not work, for example, the car was not exploited for a long time, or new brushes, lay in stock for several years, rubber aging, it loses elasticity. The refined rubber tape can not change the direction of movement of the brushes to shift and purify the glass of the car from water. To check the elasticity of the tape, it is enough with a little effort to take to the side of the finger and let go. The tape should be easily deformed and instantly return to its original position.

It remains to consider the last reason for the poor work of the wipers, the wear of the working edge of the rubber ribbon. Usually, with intensive operation of the car, the brushes have to work a lot, removing water from the windshield, along with dust and sand grains. Sometimes, even a solid dirty story. This form should have a working edge of a new rubber tape. As you can see, the working edge has a rectangle shape.

The windshield of the car during operation is covered with numerous small chips and scratches. Thus, over time, from friction about grain chips and scratches on the glass, regardless of the manufacturer and quality of the rubber ribbon, its working edge is spinning, ceases to urge the water film and glass after the passage of the brush, it remains not transparent enough. Straight corners in the worn edge of the rubber ribbon are captured and take the look as in the photo below.

Typically, the brush is still in good condition, but with the worn corners of the working edge of the rubber ribbon, replace the new, without thinking that the rectangle can be restored by a simple reception, with the help of sandpaper, driving the rounded part from the working surface of the ribbon.

Repair of automotive brushes

If it is determined that the cause of the working capacity of the car janitor is to wear the working surface of the edge of the rubber ribbon, then it is possible to restore it, without even removing, the janitor with a wiper leash. To do this, take a plate of a negligent material, for example, a multi-layer plywood and stick a sheet of the same size of fine-grained emery paper. The plate will be larger in length, the better the edge will be better.

The main thing when performing this work began to complete the rubber tape evenly along the entire length, in order to prevent failures, otherwise in these places when the janitor can remain on the glass.

It is even better to perform grinding rubber tape by gluing the sandpaper on the plate, in length exceeding by 10-15 cm the length of the brush itself. Then the work will be done much easier with the best end result. After each multiple passes, it is necessary to check the result to be direct corners and not to restore excess rubber, as it is still useful in subsequent repairs. In this way, the ribbon can be restored several times.

If the rubber tape has finally become unusable, and the frame is still in good condition, it is advisable to replace it new. It is possible to replace the use and torn from the movable side along the cervix line used by the rubber tape, removed from a longer brush. It is not difficult to remove the rubber ribbon.

First you need a screwdriver blade a little to the side of the retainer retainer of the rubber ribbon.

Rubber tape is removed from the paws of the ribs. Elastic plates are removed from the tape. Sometimes the elastic plates are curved, and it is necessary to remember which way to adopt in the groove of a new rubber tape. Sometimes samples in the plate are smaller than the protrusions in the ribbon groove. Then you need to properly fit the samples in size.

A new rubber tape prepared for replacement is made by a groove through all fishery support fixtors. The tape should freely, but without a backlash, move along the rumor. If any of the support does not provide free moving or tape in it too free, then it is necessary, respectively, sliding the paws or squeeze them.

After refueling the rubber tape of the janitor in the foot of the rocker supports, it will remain pliers to compress the lock and the brush is ready for installation on the vendor of the car wiper.

As you can see, spending only ten minutes you can give the second life with a brush. Especially relevant to such repairs for expensive branded janitors.

How to choose brushes for wipers wipers

First that length brusheswhich must comply with the requirements of the car manufacturer. If the brush is shorter than it is supposed, the glass cleaning area will decrease, which will lead to a decrease in the road viewing angle. In the case of a larger length, the pressure per unit of the length of the rubber ribbon will decrease and the spring of the leash is insufficient to press the rubber ribbon of the water layer and the glass after passing the brush may remain non-transparent after passing.

Next need to check whether adapterMounted on the brush purchased or the presence of additional adapters for leashes your car. The most common type of fastening of janitors to a leash is a "hook". Usually all brushes are equipped with an adapter for him.

The third criterion is tape quality. At its planes, especially on the working, borrowers and irregularities are not allowed. The tape should be elastic, homogeneous texture and color. The working edge must have a straight angle along the entire length of the tape. The same requirements for the tape are presented when it acquires it for the restoration repair of the brush. Ribbons in expensive janitors are silicone, graphite-silicone and teflon, they are more resistant to wear, as they have a reduced friction coefficient, but also the price of them several times higher than tapes from rubber.

It remains to check the frame and the freeness of the movement of the tape in the root of the rocker. The rocker in the hinge joints must necessarily be with plastic liners and there should be no backlash, but the freedom of movement of the rumor relative to each other remains. The tape should freely move freely in supports, except for its extreme fixing. It is easy to do, pulling the ribbon to the brush of the janitor from the frame.

In the three storyline roller, it is shown how in practice, check the freedom of moving the brush of the janitor in the supports. On the first plot of the tape overly clamped in the supports of the risk or the dirt was stuffed, such a brush requires repair or replacement. In the second and third plots, respectively, the response of a properly fixed rubber ribbon in the rocker is a short and long brush. According to the oscillations of the rubber ribbon, it can be seen that the necessary freedom of moving the ribbon in supports is available.

Many polemical conversations are underway on manufacturers of brushes for a wiper, but in any case all the brushes are made in China. Only brand are produced under the supervision of well-known firms. To find out for a fake or not, unprofessional is difficult. Therefore, it is necessary to rely on an external inspection. If the brush's brush or repair tape meets the above requirements and pleases the appearance of your gaze, then with a high probability it can be assumed that it is high quality and last for a long time. Such a brush and should be purchased for your car.

Hello everyone. That's the next update of my section "Crazy handles." And as usual, we will do it all and in the field.

I am sure, many motorists have an idea that there are wiper brushes (in commoners - wipers), and the fact that they have plastic plugs on the sides, which fix the rubber band, cleansing the windshield from water, snow and dirt. It is this plug that we will repair today, and more precisely to fix the gum, because The plug somewhere lost on the road ...

Immediately I apologize for the quality, I had to take pictures with a tablet with a pair of camera.

The case was so, went beyond the city, on the way they lost the plug, in the district not a single auto store. There was nothing to do, I had to repair from the remedies to make the windshield not to scratch during the rain.

That's actually, the plug looks like:

And this is what we will repair:

As can be seen from the photo, there is no stub on the end of the wiper brush (janitor), because of what the gum is constantly running away, and the "ribs", which must hold it - drove around and skryabat, which can lead to not pleasant scratches.

The structure of the frameless brush of the wiper is extremely simple, and therefore repairing it does not take much time. For repair we need:

1. Stationery or construction knife;

2. ;

3. Confidence in their forces.

For a start, I defined the place where the clamp will take place to fix it tightly elastic. If you look at the photo, it can be seen that the "ribs" have symmetric recesses. That is the level of them and we will make a through hole in the gum of the janitor for dense fixation of the clamp.

Doing the hole is extremely not convenient, because Rubber tight. Therefore, we do everything very carefully, and it is desirable that the hole is not very wide. What it is wider, the easier it is to break the gum, rubbing through it the tie.

Then, you need to turn the screed through the hole. Please note the screed lock on the installed janitor was closer to the hood than to the glass. Otherwise, he may interfere with the dense fit of the janitor to the windshield and scratch it.

Pay special attention to how the screed passes. A rubber band of the wiper wiper has a "gills". It is between them I did a hole to keep the cleaning properties of the janitor. Otherwise, the adjacent rubber to the glass would not be dense, and the repair of the wiper brush would give only a visual effect.

Taken? Wonderful. Now neatly begin to delay, not forgetting to correct the castle of the screed. It is necessary to correctly correct, so as not to disconnect the hole in the rubber band.

After tightened, the chatter end is sprinkled with the same stationery knife.

Well, actually, as I did in the end. In my opinion, it turned out not bad. Yes, and by car, after installation, it is not noticeable, if certainly not to know and do not look after ...

Unfortunately, I forgot to take a picture of what the wind cleaver brush looks like on the car ... But I will say one thing that I got back in the rain. The brush has saved its original function and did not scratch the glass.

I will not say that repairing the wiper brushes, which I described in this post is ideal, but, as I have already written above, the repair was carried out in the field of progressive means. What I found, I screwed)))

Time spent 10 minutes from the strength. I strongly recommend using this method only in emergency situations and at the very first opportunity to replace the brush of the janitor. The benefit of the prices of them is not very high, and you can only spend on one, and not for the kit. Do not save money on your own security.

This is probably all. All questions, additions and thoughts are left in the comments.

P.S. Do not forget to subscribe to my updates and, talk about the project to friends, leave the detailed comments on the topic, make the retweet, put the huskies, click on "I like" and ... well, you yourself know everything)))

Thanks for attention.