Removing rust with car body: stages of work, means and recommendations. How to cope with rust on the car body? How to deal with rust by car

Corrosion or rust body is a patient the theme of any car enthusiast. If such an infection falls on the body of your car, and you will miss the time or do not notice corrosion, it is a malicious rust to stop the roots throughout the body and the bottom of the car and after a while you will see holes on the body of your favorite "horses". To prevent the spread of rust and remove it, the car enthusiast should take into service various ways to deal with rust.

If you at school did not skip chemistry lessons, you must remember that corrosion is the result of the interaction of metal with water, air, with chemical reagents.

Finding on the metal, the chemical reaction occurs and the result of this reaction is the oxide of iron and hydrogen.

And since your work machine is in constant contact not only with water and air, but also with chemical reagents (especially in winter) we get rust on our car.

Anticorrosive processing can prevent corrosion on the car.

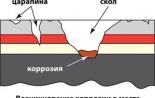

Modern car body consists of a thin steel sheet on which a thin layer of paint coating is applied.

Any bulk or scratch leads to a violation of the layer of paintwork and in this place there is direct contact with the environment. The task of anti-corrosion processing is to eliminate direct contact with the aggressive medium.

Anticorrosion treatment types

There are many methods of anti-corrosion processing, in this article we present the following:

- to effectively repulsion water from the surface of the machine, the protective coating of Ceramic Pro has proven itself;

- it is good in operation Dinitrol 479 - he has established itself in the form of protection of the body from corrosion and noise insulation;

- to avoid the appearance on the body of chips and small scratches - use the carbon type vinyl film;

- preparing for the Russian Winter, to protect the bottoms from chemical reagents, make a car nise wax;

- you can advise a very reliable but dear way to protect the car from corrosion - spend galvanizing the bottom of the car;

- there is another electrochemical wayites from corrosion, but feedback on this method is contradictory, and the money will throw away the money.

Buying a new car, we are reported that the car has passed all the necessary anti-corrosion processing.

But the fact is that not all cars have high-quality anti-corrosion processing.

Manufacturers qualitatively cover the bottom and wheel arches with Dinitrol 479, paints and varnish materials have good water repellent properties, high-quality galvania is used. Therefore, cars of these manufacturers and through a quarter of a century on the roads, will give odds to our domestic cars or such as Chinese cars.

Car lubers know that the body begins to rust in the most problem places, namely:

- rust corrosive thresholds;

- wheeled arches;

- quickly disagree the locations of the details.

Sophisticated above said if you want to extend your car's life, do not forget to make anti-corrosion processing with one of the above methods.

And if you cheated and traces of rust appeared on the body, you will have to work hard.

Corrosion of the car body, what to do with rust

Answer one, remove rust.

But if the slightest chill paint appeared, the chief need to be immediately removed. Eliminate the chip in the following ways:

- with polishing, if the damage is very small and does not reach the metal;

- with painting, this is necessary in the case of a deeper chip to the soil layer;

- if deep cracks appeared - cracks need to be treated, painted, apply varnish and polishing.

You can advise motorists more often wash your cars, because the scratches and chips can be viewed under mud and dust, which will later lead to rust.

Scratchs and chips are noticeable on a clean car and you can polish the shallow chips on time or close them with a clear varnish.

If there are cracks to the ground and metal on the car, to close them, it is necessary to choose the desired color of the paint and varnish.

If corrosion or rust appeared on the car, the rust converter must be purchased to combat it.

You will have to work hard and carry out the following actions:

- with the help of sandpaper or grinding disks of medium grain for a drill, it is necessary to clean the damaged part of the machine;

- you can handle the anti-corrosion composition. Preparations such as WD-40, Rust Killer, Rust Treatment can dissolve iron oxide and degrease metal;

- after the damaged surface was processed, it is necessary to sharpen it, apply primer, paint and apply lacquer;

- polish the place of your work.

If you doubt success, you invite specialists.

Professionals Repairmen will select the necessary shade of paint, produce high-quality polishing and you will not be able to find the place of your ex-rust.

The galvanizing of problem seats is done at home, in this case, on problem areas, zinc settles a thin hoist.

How to process your car zinc, we will tell in the following articles.

Corrosion sooner or later may appear on any car, and the sooner you start fighting it, the less the body will suffer. But how to get rid of rust so that on the affected area she no longer appeared and at the same time the car returned an attractive look? The phased description of the rust removal process with the subsequent we prepared for you in the article.

1 Body preparation, or where to get started?

Before removing the foci of rust from the body, it is necessary to thoroughly wash it so that the car's surface is perfectly clean. The fact is that the affected areas are poorly visible on the dirty surface, besides, without compliance with this requirement it is impossible to qualitatively follow the subsequent finish and protection of metal from corrosion.

If access to the affected corrosion is hampered by access due to other parts, they must be dismantled. It may be a bumper, molding, turn signal, emblem, etc. In addition, the surfaces around the affected rust area must be saved by painting scotch, so as not to damage them in the process of work and not stain paint. This prepared actions end.

2 Body repair materials - Tools

To high quality and quickly get rid of home from rust on the car body, you must prepare the following set of tools:

- angle grinding machine or even an ordinary electric drill with a special nozzle in the form of a metal brush;

- sandpaper with abrasive P120, P600 and P1000;

- rust converter type "zincar";

- degreaser;

- polyester resin for lamination and glass cholester.

- anticorrosive primer;

- putchal with fiberglass;

- spacure without filler (finish);

- paint.

It must be said that there are repair kits for combating rust, such as "zincor-car". They contain three components - the rust converter, a degreaser and an anti-corrosion coating, as a rule, based on zinc. Such sets allow to eliminate small foci of corrosion.

3 We remove corrosion with minimal loss of forces and time

As you know, there are two methods of combating corrosion:

- mechanical;

- chemical.

The greatest effect can be achieved if you fight rust comprehensive. Therefore, we will further apply both methods at once.

We start working with mechanical processing of rusty places. To do this, it is better to use the grinder or an electric drill, as it is high enough to clean it hard and long. Rust must be removed with the old paint and the layer of old soil, i.e. It is necessary to work before the appearance of a pure shiny metal not only on an affected rust plot, but also a plot around it, a width around centimeter-two. When the surface is cleaned, pass the P600 sandpaper from above, if necessary, clean the hard-to-reach places manually.

If you do not have the power tool at hand, you will have to eliminate the paint manually. To do this, use the skin with a grain P120. Then make the P600 brand in the skurt. If the metal rotted through, it is necessary to expand the hole to the "living" metal. The prepared surface is then treated with rust converter. The chemical will allow to get rid of even from microscopic traces of corrosion.

Do not use more rough sandpaper than P120, as it will leave deep scratches on the surface, which will have to put out.

Before using the composition, shake it carefully. Then, with the help of a sprayer, tassels or even rags, apply a liquid so that the surface is carefully moocked. After that, stop working and wait until the composition is completely dry. Next, process the surface with a metal brush to remove the residues of the converter that did not react, as well as the transformed sandpaper.

For the greatest effect, the procedure must be repeated. At the end of operation, the processed area must be thoroughly rinsed with water and then wipe dry with a cloth. Note that this is a mandatory requirement that cannot be neglected.

By this principle, process all rusty points on the surface of the car.

Most often, corrosion appears on the doors under moldings, where dirt and moisture accumulates, as well as on the thresholds. Therefore, dismantle all the attached parts on these areas, as the rust can be hidden under them.

4 We restore the damaged area

So, with the removal of rust, we successfully coped. Now it is necessary to immediately begin the anti-corrosion processing of the prepared area, otherwise, after a few days, new traces of corrosion will begin to appear on the surface. Work is starting with metal wip degreasing. To do this, simply feed the rags in the liquid and then wipe the stripped metal.

Next, it is necessary to apply anticorrosive soil on the surface. It not only protects the metal from corrosion, but also improve adhesion between the base and putty or paint and varnish material. The soil is applied using a sprayer or ordinary brush. After drying the first layer, apply the second layer and then the third one. Read more about the use of soil, read in the instructions from the manufacturer. The fact is that different soils have their own nuances that need to be considered when applied. Thus, treat the primer all stripped from corrosion space.

Anticorrosive primer allows you to stop the process of corrosion development. Therefore, if necessary, after its application, you can take a break in work, but it's not worth it anyway.

After that, you need to close holes, if, of course, they are available. For sealing a small hole, use the fiberglass putty. Apply it with a spatula as an ordinary solid surface. Due to the sufficiently thick consistency and the presence of fiberglass in the structure, it will not fall into the hole.

If the hole is more, with a diameter of 2-3 cm, with the back of the metal, you can put the greasy tape. If the hole is large, i.e. More than 3-4 cm in diameter, it can be sealed with a glassball, which is glued with a polyester resin. To do this, pre-cut the glass of the glass bag so that it will be placed on the 5-10 centimeters to overlap intact metal. Then mix the resin with the hardener, as a rule, the latter is added in an amount of 3% of the amount of resin.

Keep in mind that the "vitality" resin is about 10 minutes, after which it hardens and grabbing. Therefore, immediately after kneading, apply it to a brush on the prepared surface and attach a fiberglass latch to this section. Melt the surface of the planes to the resin so that it is completely soaked. After pouring the resin, it must be pasted with sandpaper to remove all major irregularities.

If the body damage is insignificant, the surface can not even be putty, it is enough to apply several layers of soil, after which you can start painting.

Then apply the finish or universal putty to the surface with a thin layer, trying to smooth it as careful as possible. After drying, the coating is cleaned by the sandpaper "zero". Next, the surface must be carefully cleaned from dust. In order for the paint, the spots did not show up and the paint itself was well, apply another layer of primer on the surface. After pouring, the soil must be pulled by the sandpaper "zero", pre-operated in water.

After that, the prepared surface must be painted. To repair a small area, you can use the paint in the canister. If you need to cut a very small plot, you can use a repair pencil with paint or paint in small tubes, which is sold with a tassel like a female nail polish. On this, actually, repair of the body of the machine and completed. The only thing can be applied on top of the paint varnish and then polish it.

We offer you to finally get acquainted with some useful rust removal tips:

- the best quality of corrosion removal by mechanical way can be achieved using a sandblasting machine, since it allows you to process even the smallest pores, but does not change the thickness of the metal;

- to eliminate rust with a chemical way, immersible transducers can be used, which convert rust into a protective film suitable for applying finishing materials;

- if the grip rust is carried out manually, wet the sandpaper in White-Spirit, which will slightly increase the efficiency of work;

- if you do not have a rust converter, make it with your own hands. To do this, by two liters of water, add grams of 15-20 oxalic acid, as well as some lemon acid and food soda. The resulting liquid needs to be treated by corrosion areas and wait 3-5 minutes. Then the surface must be rinsed well;

- instead of a degreaser, you can use the usual detergent for dishes;

- when the rust is removed, overlaps a piece of paint from the car and save it, it will make it possible to accurately choose the paint for the body color.

Here, perhaps, all the highlights, knowing which you even can perform high-quality repair of the body of your car.

As practice shows, not all motorists care about the body of their vehicle. And very in vain, because even the new iron is subject to corrosion. For some reason, people are confident that they will always be able to sell the car to another person when the first problems appear. But practice shows that even foreign cars can rust can rust, where the car was made and what is its price. If you are from those people who are ready to take care of the body of their car, then this article will be very useful.

Where to begin?

To begin with, carefully inspect the bottom of your car. You can do this on the overpass or observation pit. The greatest attention is paid to a number of problem areas - thresholds, wings, spars. Most often rotten the so-called pockets where water is constantly accumulated. Of course, in such places there should be special holes for water flow, but, as a rule, they turn out to be painted or scored mud. In this case, you can clean the old or additional holes.

After checking the drain holes, inspect the quality of anti-corrosion processing. Special attention is paid to the places described above. Very often, anti-corrosion processing is done poorly and not all places can be covered. In general, covering problem areas with special compositions is preferably before the appearance of rust. Otherwise, you will have to first prepare the surface (remove any traces of corrosion), and then apply special compositions on the body.

Features processing

There is no special complexity in the processing procedure. It is necessary to stock high-quality metal brush, several brushes (shape and sizes should be different), sandpaper, rag, White spirit and directly the most mastic. In the hands there must be gloves (skin must be protected). Special attention is paid to getting rid of rust on the surface. If this is not done, then all efforts may be in vain. Moreover, applying mastic over the existing rust can only aggravate the situation.

To begin with, get rid of the dirt that adhered to the bottom of the vehicle. This can be done with a powerful jet of water. If there is no special apparatus at hand, go to the nearest sink, where experts quickly and efficiently wash the car.

After the whole dirt is removed, and the bottom is perfectly cleaned, it must be dried or wipe it with a soft cloth. After that, suspicious places should be processed using a special scraper or metal brush. In the case of rust detection, make the emery paper processing. Check all the cavities on the fact of the presence of dirt and water.

As soon as the verification is complete, the bottom is processed using White Spirit. Only after that you can use anti-corrosion materials. Apply a mastic only with a special brush or hands (everything depends on its consistency and application features). If the viscosity of the material is low, then the processing is better to produce in several goals. Each centimeter of the surface should be treated with maximum attention. Otherwise, moisture will begin to accumulate moisture and the body, which will speed up the corrosion process.

The best option is the use of bitumen mastic, which has excellent viscosity. It is enough to apply a spatula or hand into one layer to ensure maximum protection. Such a material is not afraid of frosts, so you can not worry about the safety of the body of the machine in the winter. As for wax compositions, they are also well suited for covering the body. The optimal version is the processing of bitumen and wax mastic. At the same time, remember that even in the case of double processing about 100% of efficiency and speech can not be. The risk of corrosion remains always.

Another popular anti-corrosion agent is Movil. Its advantage is that the composition can be applied even on an unprepared (not cleaned) surface. Moreover, due to the liquid form of the product, it can be poured into the most hard-to-reach places, which allows you to fully process the car. Movil is applied using special sprayers. You can buy an "anti-corrosion" in the canopy and significantly simplify the task.

Some subtleties of the process

Remember that you spend processing for yourself, so all the extra details that can interfere with efficient processing, it is better to immediately remove. If in any cavity you can not find a hole for filling the lubricant, then drill new (naturally, it is necessary to do it with the mind, given the design features of your car).

Chrome details should also be processed. At the same time, stock specialized compositions intended for these purposes. In the store, be sure to specify that the product is suitable for processing precisely chrome details. Otherwise, the appearance of the product will be significantly sought.

Main types of protection used

Finally, let's remember what types of corrosion body protection are used today. There are several of them:

The cathode is a special type of electrochemical protection, when a special cathode "protector is applied to the most problematic part of the body. When moisture gets into the body, it reacts and takes the harmful effects of rust on itself;

Printing is one of the oldest methods of surface treatment. In recent years, has already lost its relevance and practically not applied by motorists;

Galvanized. In this case, the metal is covered with a special layer (its thickness is about 8-9 microns). One of the most effective methods of protection against the appearance of rust;

Electronic. According to manufacturers, protects against corrosion for up to 10 years. It has a kind of special instrument.

Output

To protect the body from corrosion and extend the life of his life, you must monitor the state of the metal and from time to time to produce anti-corrosion processing. Otherwise, the car will lose a trade look very quickly. Good luck.

Probably, most car enthusiasts after the acquisition of a new or used car in second place after the problem of protection against hijacking is a question fight With corrosion body?

For a new car, on the body of which there are no corrosion foci and the factory coating new and clean, these are preventive order measures. However, they give the maximum effect.

For a used car, proceed from the fact that its body is more or less struck by corrosion and it is impossible to completely get rid of it. Therefore, in this case, it is necessary to maximize its action and protect the disabilities.

Follow the body, wash, polish it, and it will be securely protected. The bottom, even treated with the most persistent mechanical effects of polyvinyl chloride plastisole, can not resist the exposure to sand, gravel, salt and temperature differences. Under the influence of these factors, the factory coating gradually collapses.

Wings are in the same position as the bottom. Moreover, the wings have also pockets where dirt and moisture are going and accumulated. Even a new car has a sense before starting operation, remove the wheels and pickyly inspect the quality of the application of bitumen mastic on the inner surfaces of the wings, especially in the location of the headlights. And at the factory can be mistaken, as a result, such a wing becomes a "victim" of corrosion.

Internal cavities of thresholds, bases of central racks, spars are no less vulnerable. They are processed at the factory, but the probability of flaws is not excluded. In particularly serious position, the thresholds turn out if the drainage holes are clogged, intended for drain penetrated into the water thresholds.

Subject to the additional anti-corrosion protection just purchased by the car - the case is simple. Only material and tools are needed to apply it. It is much more difficult to fulfill this operation by car, which has already been exploited. Here the lion's share and physical effort should be spent on the preparation of the surface.

It makes no sense to postpone this dirty, time-consuming and responsible operation for later. Take care of the car processing, after preparing a metal brush for work, a wooden scraper, sandpaper, brush, white spirit, rust converter, anti-corrosion mastic and rag.

What contributes to the appearance of rust?

Water is the first enemy. It contributes to the appearance of rust, and this is very well known to those who live in areas with a wet climate. For example, take the VAZ car. If there was no anti-corrosion treatment of the body on this car, then the moisture together with the road salt and dust is capable of leaving the car through rust on the body.

Getting started, it should be remembered that work and funds will be spent not in vain only subject to good surface preparation. It must be carefully cleansed from dirt, old destroyed coating, all kinds of fats. Only on a clean low-fat surface, the adhesion of mastic mastic will be reliable. Rinse the prepared surfaces best with a powerful water jet under pressure.

Getting rid of dirt, you can see, in what state is the old coating. If it began to flap, the metal brush and the scraper will bring the matter to the end. Metal brush is a reliable tool and cleaning from loose and plastic rust. After performing draft work, the surfaces stripped by the sandpaper is degreased using White Spirit.

Chemists invented one very effective composition - Rust converter.

The easiest and easier way to get rid of the corrosion of the body. This substance converts rust on the body already in a disadvantage, as a result of further growth corrosion. In a short time, such a composition applied to the red rust surface will create a miracle.

Redhead raids will become grayish, and the rust is converted into a more stable and no harmful connection. The surface-processed surface is ready to apply anti-corrosion materials on them. Mastics and pastes depending on their viscosity can be applied with a brush, spatula or hand in a mitten. The main condition: there should be no bare seats.

Most technological for hand-made bitumen mastics. They are well opposed to the action of moisture and salt, but not enough rack against sand and rubble, and also differ in low frost resistance. At low temperatures, the coating becomes fragile, and sufficiently blow a stone so that the mastic began to crumble.

Often, wax formulations are used for short-term protection of the bottom and wings. They have their advantages and disadvantages. They penetrate well inside and fill the pores, cracks, flanging and pockets, but they do not bring shocks. By reflection, the inventive motorists decided to apply wax formulations on top of bitumen than provided smaller fragility at low temperatures.

As already noted, all the details having a box cross section are particularly subject to corrosion. And it is not by chance. In cavities due to insufficient ventilation, always wet. In the cracks between the welding points there is access to water and dirt, and if we consider that these cavities do not always manage to treat anti-corrosion compositions, it will be clear why corrosion "chose" these places.

Until the 50s, hidden cavities were practically not processed, they saved them only a significant thickness of the metal. The so-called ml developed in Sweden is the method of combating corrosion (from the first letters of the name "Motorman Laurine") allowed "to lead" the process of aging and wear of box structures.

Naturally, the new method required the corresponding materials that could be sealing hidden cavities, as well as a uniform thin layer spray them all over the surface. This required special equipment. The domestic drug specially designed to apply material to hidden cavities is Movil.

The drug is interesting in that it can be applied on the surface, which were previously covered with liquid oil and affected corrosion. This is important, since it is not always possible to clean the inner surfaces of the boxed structures from old coatings.

Car owners have to solve serious problems associated primarily with the lack of equipment for applying the drug. To make a few challenge the task of those who, without having another opportunity, decided to independently treat the body, we will advise you to take advantage of the experience gained in this area. In principle, the necessary equipment is very simple.

It works on the basis of air spraying under the pressure of 4-6 kgf / cm, which is quite enough to spray the Movil preparation. A worker has been developed - a nozzle, which creates a torch of sprayed material. The nozzle using a tubular plastic elastic extension can be connected to the Cro-1 gun and is entered through or re-drilled holes into the zone of a box element.

If you do not have such an apparatus, we offer homemade structures of installations and sprayers. Everything is suitable here: manual and foot pumps, paintopulizers, sprayers, sprayers.

Here is one of the simplest structures.

You can use a nozzle from a conventional cologne spacing, sprinkling it to the brass tube and drums a nozzle by 1.2 mm in the tip. To the inner wall of the tube, you need to solder a brass tube through which a preservative enters.

The pump (it can be more powerful) the hose is connected to the tube. To supply a preservative to the tube used polychlorvinyl Cambridge. The sprayer of such a design provides the torch of the sprayed preparation of Movil with a diameter of up to 0.2 m at a constant air supply,

The places of applying anticorrosion material under the hood and in the luggage compartment at the maintenance stations are washed with water. At home, where the possibilities for drying are limited, you can thoroughly wipe these places with a damp cloth. It is convenient to carry out the body to carry out the body on the lift.

The main number of processed points is located on the bottom.

To get inside the thresholds, to a niche of a spare wheel and crossbar under the front seats, you need to get special rubber plug plugs. They are located two on each side under the front wing, one piece on each side in the rear wheel arch, in the center of the recess under the spare wheel, one on each side in the crossbar under the front seats. You should also clean the drainage holes of the thresholds.

The bottom, the arches of the wheels and the hard-to-reach hidden cavities must be rinsed well under pressure under pressure, otherwise the work done will be in vain. With the help of compressed air, it is much faster than driving the washed bodies of the body. So that the wheels do not interfere, it is advisable to remove, installing the car on the stand, and the discs, brake drums, rear axle, drive shafts and gearbox should be wrapped with paper. It remains to open the doors, the hood, the trunk lid and you can begin processing.

If you inspect the bumpers and caps of the wheels of the car, which was operated more than 4-5 years, then definitely detect them tracks of corrosion. Consequently, chroming is not such reliable protection. Indeed, the chromium coating has a weak place - this is a porous coating. It is for this reason that the details first cover the layers of copper and nickel, and then chrome.

However, moisture, salt, sulfur gas, and for them and corrosion find ways and penetrate into the coating through the pores. One thing is clear: decorative details must be maintained in good condition. These details can be divided into two stages: cleaning from dirt (car washing); Immediately removing corrosion and traces of sweating.

The coating layer (copper - nickel - chrome) is very thin (90-10 μm), so wipe bumpers, caps and other decorative chrome details with a dry cloth are harmful. The coating is scratched and intensively destroyed. After washing, the details wipe dry, and then processed by the "chromed detail".

It should not be carried away by this composition, since one of its components is an abrasive material, which, removing corrosion raid, removes the coating layer at the same time. The use of a chromatic cleaner for chrome parts once every 2-3 months should ensure good condition of these parts.

In winter, the surrounding environment becomes complicated, and protective varnish or lubrication comes to the help of the "tacifer for chrome details". Covering the details, do not forget about their reappets, as items have a feature to rust from all sides.

And now I will talk about the last method of combating rust.

In my opinion, this method is the best and successful. This method is based on electrochemical processes. Unlike liquid anticorrosions, this method requires ten times less time. This method is considered the most reliable in the fight against metal corrosion. There is a zinc that settles on the metal and does not allow rust to appear again. I think everyone heard about a galvanized body which is not amenable to rust?

Such a set is called "zincor-car" into the composition of which the solution includes a solution for degreasing and removing rust, as well as a solution for applying a protective coating.

When working with zinc drugs, you first need to remove rust from the selected section of the car body, and then process the section moistened with a cotton swab, which is connected to the battery over the wires. After this operation, the zinc particle is settled on the car body, and the area treated by you becomes grayish.

The body is the most expensive and represented part of the car. Many motorists choose the car precisely in its appearance, and not by speed or other indicators. Each car manufacturer applies its own methods of painting the machine and processing its body to maintain its original look as much as possible. But there is such a nuisance as a rust, which is subject to all cars without exception. If the body of the machine began to rust, you must urgently eliminate the "focus" of the problem, and you can do it with your own hands.

Because of what rust appears by car

When a rust appears on the car body, it instantly loses in the price, and even in the secondary market to sell the car with corrosion on the body will be very difficult. Professionals will always be able to determine whether the work on the body of the car to eliminate the manifestations of rust or not, that is why it is better not to bring it to such a situation.

In order for the car body metal, corrosion did not appear, it is necessary to take care of it:

Corrosion can be divided into two types, which differ in the degree of danger and reasons for the occurrence:

As part of this article, it will be considered how to deal with wet corrosion on the body of the car and eliminate rust independently.

Any car enthusiast knows that the rust on the car body is formed during damage to the paintwork, for example, after an accident. But in a relaxed situation, corrosion can manifest themselves on the metal, and most often it happens on the areas of the joints of the parts of the machine body, for example, near headlights, radiator lattice or moldings.

The process of the appearance of rust on the body of the car can be divided into three stages:

In order to avoid the destruction of the car's body as a result of the active action of rust, it is recommended to inspect the thresholds, wings, bottom and other elements of the machine for the appearance of signs of the first stage of corrosion on them weekly.

If during the inspection of the car, corrosive body damage was discovered, it is necessary to eliminate the problem as soon as possible. To remove rust by car, you will need to stock the following tools:

Depending on the corrosion stage, the set of necessary tools will vary.

When the necessary set of tools is prepared, you can move to the elimination of rust on the car body. This procedure is performed as follows:

As you can see, remove rust from the car yourself very simply, and with such a task, any car enthusiast will cope.