Restoration of old car batteries. Restoration and repair of the car battery - how is it done? Rollover - the last chance in a hopeless situation

The car battery serves as a stable source of voltage, but unfortunately, its service life is limited. If on your car he began to serve the first signs of wear, do not hurry to change to a new one, because the battery can be restored with your own hands.

Signs of battery wear

To understand that the life of the battery comes to an end, you need to know several non-hard features, and carefully treat your car:

- Fast charge loss will be the first call, talking about the violation of the device. This sign indicates a reduction in the quality of the electrolyte.

- Another faithful sign will be fast charge with quick discharge. The reason is the started sulfation.

- The electrolyte darkening is a serious reason to think about how to restore the car battery, because this is a sure sign of destruction and sprinkling coal plates.

- Heating of individual sections of the device and boiling electrolyte becomes the result of damage and closure of the plates. One of the reasons for such a breakdown can be a long-term car during severe frosts. When freezing, the plates may be damaged, and even the instrument housing. The result is numerous closures and, as a result, too fast boiling electrolyte when charging. Such a device is most likely not happening.

Almost in all cases, with the exception of running, the car battery can be reanimated. And although it will not always be cheap, but still cheaper than a new device. From how the battery is operated and how attentive you are to various kinds of malfunctions, the battery life depends.

Before dealing with how to restore the car battery, It is necessary to find out what is actually subject to recovery.

Check the density of electrolyte

The electrolyte is a solution that fills the battery. In the most popular among motorists, a lead-acid car battery, it is a sulfuric acid cocktail and distilled water. Alkaline electrolyte is used in nickel-cadmium and nickel-iron batteries.

Before reanimating the car battery, the electrolyte density should be measured. This requires a special device - a carometer. It is inexpensive and sold at any auto parts store. The procedure for checking the solution is simpler and will not take much time. On the video you can see the entire procedure:

The acid density can also be measured with a voltmeter. To do this, you need to connect it to the car battery terminals. In calm state, the indicators should fluctuate within 11.9 - 12.5 V. After that, you need to start a car, Dial 2.5 thousand revolutions and make measurements again.If the voltage in this case varies in the range of 13.9 - 14.4 V, the electrolyte density is normal and the device simply requires additional recharging.

How to restore the car battery if the problem with the quality of electrolyte is revealed? Perhaps this problem is the smaller of the evils associated with the battery. Electrolite, in contrast to other parts, such as the plates, is easily treated. It is possible to restore it different ways:

- charge the battery with a special device;

- completely replace the solution;

- add an electrolyte of high density;

- add only sulfuric acid;

- add only distilled water.

Before reanimizing the acid solution, it is worth trying to recharge the device. It is possible that it is all this measure that will be limited. Moreover, she will not cost you anything. If nevertheless, after charging, a problem with an electrolyte density is detected, then restore the car battery can be changed by a change in the density of the solution.

Attention! In no case do not pour distilled water into concentrated sulfuric acid. Acid should be added to water. Otherwise, you risk getting serious burns from splashing boiling water in acid. This applies to the manufacture of new electrolyte. Dilution of too dense water solution is not as dangerous.

If the process of destruction and closure of plates began

Having found the destruction of the plates, be it a darkening or boiling electrolyte, you need to urgently take measures to resuscitate. A car battery, which detected significant destruction, will not be able to restore. Therefore, before reanimating the car battery with your own hands, make sure that this occupation will not be useless.

When detecting the process of destruction, You should rinse with distilled water:

- define the battery by connecting the load (for example, a light bulb);

- remove from the cans a damaged solution with rubber pear and place it in specially prepared glass dishes;

- rinse the cans with distilled water until it is possible to restore the purity within the cans. When washing the battery, you can shake and turn over. If the garbage is too much and after multiple washing, the coal crumb continues to crumble, most likely, the process came too far. In this case, to reanimate the battery do it with your own hands;

- having achieved clean water at the exit, pour a new solution into banks, checking the pre-density.

- put the battery for recharging and restore the voltage;

- check the electrolyte density in the charged device and, if necessary, correct the indicators.

Diagnose sulphate

One of the most frequent enemies of the car battery, of course, can be considered sulfate. Under normal conditions, reversible chemical processes occur during charging in the battery. However, over time, especially if the car is exploited rarely, these processes are disrupted: large labor-soluble lead sulfate crystals are formed on the plates, under which the recovery of active substances becomes difficult. The consequences of such an improper crystallization become:

- reducing the battery capacity.

- increase internal resistance.

- increase the volume of plates.

Sulfation can be a consequence of long standing of the car, overheating, critical flow conditions. The beginning of the sulfate is determined by a sharp drop of tank. It uses a special tester for its definition. Having found this trouble, you should think about how to reanimate the car battery in the shortest possible time until the device can still be restored.

To restore on your own car batterywhere sulfate was detected, a special additive to the electrolyte is a desulfactor, capable of dissolving large crystals. About this Read more on video:

Chemical ways of recovery do it yourself

Professionals allocate the following ways:

- The easiest and most cheap way to reanimate the battery is as follows: clean the banks from the electrolyte completely and fill them with distilled water.Watch out the battery with a weak current (0.01 from the capacity). Lead sulfate at the same time will begin to gradually move away from the plates, forming a new electrolyte. After two hours, make a break, and then start charging the device again. Several such cycles are sharply reduced sulfate, and the electrolyte that has newly generated in banks will again gain performance.

- Charge the battery and drain the acid solution. Then, as it should, rinse the cans with distilled water and pour into them the solution of drinking soda (concentration - 25g / 1l). Withstand 2-3 hours, Replace the contents with a solution of the cook salt (at the same concentration) and charge the device for an hour. After that, increase the salt concentration to 4% and fully charge the battery. Rinse the cans with distilled water, fill in the electrolyte and fully charge the battery.

- Charge the battery, drain the electrolyte and rinse the banks. Pour the trilon solution b and ammonia. You can purchase a solution in chemical laboratories. It should be stored in a dark ventilated room, in a closed form. The desulfation process lasts for about an hour, after which the chances of reanimating the car battery will increase significantly. In the process, gas is released and small splashes are observed on the surface. Termination of splashing indicates the end of the process. After such processing, it should be thoroughly rinse with distilled water (2-3 times). Bay new electrolyte solution, charge the battery. In this way, to restore the battery on your own will be faster.

Attention! It is necessary to understand that not any degree of sulfate will allow you to restore the car's battery. Therefore, early process detection is the right path to successful resuscitation of the car battery.

- Check the electrolyte density regularly in the battery. Remember that overheating or reloading may become the main cause of boiling. The sooner you manage to identify the problem, the greater the chances to restore the battery;

- if in the winter your car rests, the battery for a long time must be moved into a warm heated room. Remember that the engine freezing will lead it to a state, after which it will not be able to restore it;

- nominal Current Charge automotive battery - 0.1 from its container. Exceeding this threshold, you risk kill the device.

Modern rechargeable batteries remain one of the biggest problems for both manufacturers and consumers. And the point here is not so much in the potential risk of fire, but in the gradual exhaustion of the power source itself. Therefore, it is not to be surprised that with everyday charging, the batteries withstand a year or two active operation, after which their container disastrously falls and use the favorite gadget becomes problematic. It is impossible to fully reanimate the crash battery, but extend the period of active use while you are engaged in a replacement search, you can. We will talk about it today and talk.

The recommendations below are designed for a technically prepared user, because if you do not know which side approach the soldier, it is better to either contact the service center services, or immediately go to the store for the new battery.

Method number 1.

He will be able to help in cases where gases begin to accumulate due to long work inside, as a result of which the battery sweeps and does not hold bad charge.

Required tools and materials: soldering iron, slightly epoxy resin, thin needle, flat heavy item for alignment.

We gently disconnect the battery case from the top block with the sensor.

Separate the electronic sensor.

Under it should be a cap, inside which the control electronics is hidden. Carefully pierce it, for which a thin needle will fit well. Remember that with a damaged filling to reanimate the battery will already be impossible.

The most responsible moment. We put the battery on the table and press it with the press. Keep in mind: an excessive force can bring the battery into disrepair, and its disadvantage, on the contrary, will not lead to the desired result. It is also categorically recommended to be used when repairing visks or similar to the appointment of the device.

When everything is ready, drop by epoxy resin on the hole and solder the sensor.

Method No. 2.

To reanimate the battery with a significantly reduced resource, it is not able, but a little extend to her life can. You should not count on a lot, but to ensure the power of a modern smartphone while you are looking for a replacement, the reanimized battery will be able.

Required tools and materials: any power supply (5-12 V, current of at least 0.1 A), voltmeter or tester for voltage control, resistor (power of at least 500 MW, resistance from 330 to 1000 ohms).

If you do not have a spare power supply, it will suit almost any complete from the active network equipment (switches, routers, modems). It should be pre-make sure that the parameters of the current issued by them correspond to the necessary.

We free the contacts of the power supply and connect them with the served battery: "minus" of BP with a "minus" battery, and add a resistor to the "plus" line. Be sure to monitor the correct polarity of the connection using the multimeter.

When everything is done, connect the power supply to the network. The time of procedure is no more than 2-3 minutes. If possible, control the process using the tester: the maximum allowable voltage is not more than 3.3 V.

Several important comments

Do not leave a problem battery for repair without supervision. Cases of spontaneous fire is not the theory, but harsh reality.

Periodically check the "client" temperature with a remote thermocouple, electronic thermometer or just hand. If the surface seems to you hot, and not just warm, immediately stops the repair.

You should not use excessive charge currents. Maximum that you can afford - 50 mAh. This parameter is calculated as follows: Power supply voltage to divide the resistor capacity. For example, if the first parameter is 12 V, and the second is 500 ohms, the charge current will be equal to 24 mAh.

Instead of a resistor, you can use a standard 80mm computer fan.

To avoid spontaneous ignition, it is also recommended to control the initial charging of the recovered battery.

Method number 3.

The technique is controversial and dubious, but, according to reviews on specialized forums, it helps some users, because the responsibility for possible negative consequences lies with you.

Required tools and materials: Operating refrigerator.

The battery that does not give signs of life, remove from the smartphone and put the polyethylene package to be put in the freezer for 20-30 minutes.

Pull it out of the device, let it warm up to room temperature, then charge the usual way.

Method number 4.

Curly, but inefficient resuscitation technique. But if it seems to you that the battery in the smartphone finally failed, then why not try?

Required tools and materials: Smartphone with a standard charger.

Bring the battery to a complete discharge (when the phone is no longer turned on). Any resource-intensive game or an antutu utility can help.

Fully charge the battery to 100%.

Repeat items 1 and 2 several times.

Method number 5.

Almost all professional electricians consider the order of action below, but he helped many users of old batteries.

Required tools and materials: a razor blade, a thin twig, the glue "moment".

Remove the battery from the phone.

Open a sticker with technical specifications.

Cut off the top plastic cover as much as possible, behind which the control electronics is hidden.

We find the main contacts.

For a moment closing them with any metal subject.

We glue the top cover and give her to dry.

Once again we remind that none of the above resuscitation methods guarantees 100% of the result, and the whole responsibility is entirely and completely falling into your shoulders. But if the battery is completely disconnected, and the purchase of the new post is postponed for several days, it is worth trying. But if you rarely take a soldering iron and consider yourself a humanitarian, it is better to seek help to a friend-breaking in the subject.

Video instruction

Motor enthusiasts are treated with batteries that have lost their work. Some decide to immediately get rid of an unnecessary element, going to the store for a new battery. Others for savings are still trying to restore faulty AKB, experiencing all possible methods. In both cases, the actions can be justified, since the repair of the battery is not as simple, and the presence of toxic liquids in it becomes a warning for inexperienced motorists. And yet, if you are guided by the rules of security and follow the practical experience of experienced craftsmen, the life of the battery can be extended at least half a year.

Causes of the "death" of the battery

How to restore the volume of the battery?

The most affordable repair of auto / batteries is a multiple charging of a faulty battery with minor interruptions. A series of such charges increases the stress of the element, after which it does not perceive exposure to the current. On the other hand, in the intervals between operations, the process of aligning electrode potentials is launched. Normalization of the condition of the plates contributes to the transition of a dense electrolyte into the space between the electrodes from the pores on the surface of the plates. Thus, in the intervals, the voltage on the battery is reduced and as the charges are charged, the battery gradually gains volume.

This technique allows not only to repair automotive batteries, but also restore batteries with a similar composition from other equipment and even electronic devices. In the course of simple manipulations with charges, the density of the electrolyte is increasing, gaining normal for operation. Charging time is determined concrete model Battery and, as a rule, is 6-8 hours. Breaks between them vary from 8 to 16 hours.

Full battery disulfide

There are not so often there are situations when the battery has completely lost the volume as a result of the development and damage to sulfate. Usually, up to this point, the battery or is revealed or ejected because it is impractical in such a state. Despite the severity of the lesion, and in this case it is quite possible to repair the battery with your own hands using the disulfacy method. The essence of the recovery is to feed and long hold the high voltage on the battery. But here it is not without small pauses, since the growth of voltage contributes to the intensity of gas dividing, which is undesirable in terms of security.

So, disulfide is performed according to the following instructions:

- Water poured into the battery.

- The current is connected to the power source.

- First, in two cycles of 13 minutes, approximately 14.4 V.

- Next, two more cycles are performed, but with a voltage of 14.6 V.

Subsequent extension voltage should be done until an explicit capacity of the container appears. Thus, you can repair any type of battery. But if the recovery operation does not give any results, it remains only to dispose of the device.

Operational recovery battery

This technique allows you to restore the battery within an hour. Fully discharged acb must be charged. After that, the entire electrolyte merges from it, and the cavity is washed several times with distilled water. Next is the ammonia solution, so such a repair of automotive batteries should be carried out with maximum body insulation from possible contacts with the substance.

The composition used should include 2% (weighing) trilons and 5% ammonia. Chemical mixture and will act as an activator of the disulfation process, which on average takes 40 to 60 minutes. The rapid repair of the battery using a solution should be accompanied by gas release and the appearance of small splashes. When gas evolution stops, the procedure can be completed.

Repair of battery constant voltage

This method is slightly similar to the effect on a high voltage battery, but has its own characteristics. A stable charge is supplied to the discharged battery. It is impossible to increase it, but it should not be reduced. In this state, the battery should remain 12-13 hours, after which it must be discharged a little. Under the constant voltage, the repair of the battery gives almost a 100% result in the form of recovery. This procedure can be repeated twice, and then make the voltage measurement in the battery. If it is approximately 13 B - this means that the element is correct, and it can be used. If this indicator does not exceed 10 V, then the battery can be disposed. The battery is mechanically faulty, and no other method of repair will help it.

Prevention of malfunctions of AKB

First of all, it is necessary to track the level and state of the electrolyte in the AcB sections. In addition, it is necessary to maintain the tightness of the hull and the integrity of its serving elements, among which the battery terminal - the quality of the supply of current depends on it. You should also protect the battery from external influences, especially from low temperatures. In winter, it is desirable not to leave the block in the car, and attach to the night in the garage or to the house (if it is possible to isolate it from the residential premises). Much as a work and durability of the ACB depends on how correctly the charging procedure is performed. Compliance with operational standards will allow to extend the battery life of up to several years.

Read 5 min. Views 114. Published November 26, 2015

In this article we will tell you how to restore the battery with your own hands.

Motorists with experience probably came across or his complete failure. In such situations, it is not necessary to throw the battery in the scrap and buy a new one, you can try to restore the battery. In this article we will tell you how to restore the battery with your own hands.

During the operation of the car there are many situations when the battery fails. The output battery has several reasons. We will consider them below. The main causes of exit rechargeable battery Categories are shown in the table below.

| Cause | Description |

| Age of automotive battery | Pretty old battery, whose age is rapidly approaching 10 years, it will not be possible to restore. Any restoration of such a battery does not help. |

| Lack of electrolyte | Due to the low quality or lack of electrolyte, the battery can also fail, and it will be necessary to restore it. With a lack of electrolyte, it is necessary to inspect the entire battery case. The electrolyte could simply lean through the crack. |

| Strong frosts on the street | At a pretty cold period of the year, the battery may not keep charge and quickly fail. An experienced motorist knows that strong temperature differences can quickly kill any reliable battery. |

| Circuit Rechargeable Battery Plates | If the plates are closed in one battery section, then the entire battery can go with you. It is possible to determine the closure of the plates by boiling electrolyte in one of the sections. |

| Damage to the carbon plates of the battery | Damage to coal plates can be determined by staining electrolyte into black. |

| Sulfating of the plates of the battery. | With sulfatization of the plates, the battery will also not keep charge and fail. |

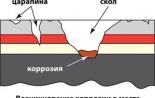

Separately, it is worth mentioning the impact of low temperatures on the batteries of cars. Due to severe frosts in the battery, the sides can bloom, and then drop out the electrolyte as soon as you start charging the battery. All these signs are talking about the watery of the battery. If the battery has been subjected to pretty low temperatures and was varying, then it will not be possible to restore it, as there will be a set of short circuits in different plates of the battery.

Next, we will tell about the possibilities for restoring the car battery. Also they will be told the best ways Recovery of car batteries. And these methods are suitable for the restoration of acid batteries, as well as such batteries that operated incorrect way.

During the operation of the car there are many situations when the battery fails. The output battery has several reasons.

During the operation of the car there are many situations when the battery fails. The output battery has several reasons. Car battery recovery

An independent recovery of the car battery is impossible without using certain materials and tools. To restore the battery with your own hands, you will need the following tools and materials:

- Pipette,

small enema,

- concentrated electrolyte,

- distilled water,

- Charger in which you can adjust the current level,

- electrolyte density meter,

- Areometer,

- Additive sulfate for electrolyte.

The first way is suitable for the restoration of such batteries, the work of which occurred with a minimum charge, equal to almost zero. To restore such rechargeable batteries for the car, it is necessary to use for them a long-time charging cycle.

The long-term charging cycle procedure must be used for the tired batteries at least twice. This reduction method is also suitable for a battery with plate sulfate.

The second way to restore batteries implies a complete resuscitation of the battery. This method can be applied when restoring acid battery. To do this, it is necessary to pour out the entire electrolyte from the battery sections, then rinse its insides with distilled water.

We will write a couple of ways to restore the battery with your own hands.

We will write a couple of ways to restore the battery with your own hands. For flushing batteries, only distilled water is suitable, otherwise, on the inner walls of the battery, third-party impurities and salts are mounted, which are present in conventional tap water.

After flushing the battery, we dilute the electrolyte with distilled water or a special additive. After that, we pour it back to the battery and connect it to the charger. With the first charging after washing the battery, it is impossible to close the lid through which the electrolyte-water mixture was poured. The fact is that the battery can highlight gas at the first charging, and if the inner part of the battery is closed, then the gas accumulation can lead to an explosion due to excessive pressure inside. By typing the first complete charge, the battery must be discharged using any electrical appliance connected to it. As soon as it is completely discharged, it is necessary to charge again until the complete charge.

The discharge and charging cycles must be carried out when rechargeable battery as long as the voltmeter shows us the voltage at minimum of 14 V. The battery capacity can be calculated using the battery discharge to 10.5 V and subsequent charging. At this point it will be necessary to mark the time of charging and indicator charging Tok.. These two indicators will need to multiply to obtain the battery capacity.

Basic Rules of Acid Acid Battery

In order for your battery to serve as long as possible, you need to stick to:

- Protect the low temperature battery in winter. If the weather is predicted for the night with a sharp decrease in temperature, then you can not leave the battery inside the car, you need to pick it up with you into the warm room.

- Controlling the level of electrolyte in battery sections. It is necessary to regularly check the electrolyte level in all battery sections. If the level is insufficient, the electrolyte must be replenished with distilled water.

- Control the battery power compliance and charger. Using an excessively powerful charger will affect the durability of the battery.

Each motorist knows how important the correct operation of the battery is the functioning of the entire mechanism. It is lead-acid batteries that are used as starter cars for passenger cars.

In this article, we will tell about the device and the principle of operation of the AKB, also it will be about the diagnosis of the battery, the most common problems and the methods of its recovery.

The device and the principle of operation of the AKB

The body of the product is expected from propylene, this material was selected for two main reasons:

- Does not spend current

- Not destroyed by acid

One device includes six batteries interconnected. A separate battery combines negative and positive electrodes (a lead alloy is taken for their manufacture, for negative electrodes - lead-calcium composition), filled with active mass.

The insulation of the opposite charge layers provides a separator from plastics. In order to improve corrosion resistance, lead-calcium alloy for electrodes can be diluted with silver or tin.

The active mass of negative electrodes consists of spongy lead, positive - from lead dioxide.

There are two types of battery:

- With liquid electrolyte.

- SO special Material, pre-impregnated with non-long electrolyte.

Today, batteries with a liquid electrolyte are most common.

The principle of operation is based on the transformation electrical Energy In the chemical during charge, during the discharge there is an opposite effect - chemical energy is converted into electrical.

The battery discharge occurs as a result of the connection of consumers: the active mass of the electrodes (negative and positive) enters into interaction with the electrolyte.

As a result, lead sulfate with water and the level of electrolyte density drops. With the proper operation of the generator, it gives charging the battery during engine operation.

Also, the battery can also be charged with a special device, as a result of the charge, lead sulfate and water turn into lead, lead dioxide and sulfuric acid, thus the density level increases.

Note! The charge must be performed taking into account the recommended electrical voltage, in case of violation of this operation rule, the service life of the device can be significantly less than the specified one.

As a result of high voltage, the electrolyte level drops, the low voltage can cause an incomplete charge of the battery. In general, the battery life is about five years, it all depends on the conditions in which the device is operated.

Instrument parameters:

- Rated container. This indicator is measured in amps-hours (Ah) depends on the energy of the charged device during the discharge (20 hours). For example, the device at 50 ACC for twenty-hours gives current 2.5 A.

- Rated voltage consists of a voltage of individual batteries, a passenger car is 12 V.

- Cold scrolling current indicates the ability of a car to start in a cold period. The higher the indicator, the easier the engine to start in the frost.

Akb faults

The battery, like any mechanism, may fail, as a result of which it will not work incorrectly either stop working at all. Below we will look at the most frequent problems in the work of the system and teach how to fix them.

Very often, car owners face the problem of the oxidation of the conclusions, as a result of which the current supply is stopped and the opposition increases in the chain, thus the entire electrical system comes out.

To solve the problem you need:

- Remove terminals.

- Clean the terminals and battery conclusions.

- Now we put everything in place, check the correctness and reliability of fasteners - the terminal should not move or depart from the output.

- It is recommended that the terminal is lubricated by technical vaseline.

Many drivers complain about the rapid discharge of the battery.

There may be two reasons for this:

- Pollution of electrolyte located inside the device.

- Contamination of the device itself.

In this case, it is necessary to remove the battery and wipe all contacts well, pay attention to the instrument can not be left wet. Next, you need to check the purity and level of electrolyte, if necessary, it is necessary to replace the liquid to the new one.

How to diagnose a car battery

Before you begin the diagnosis of the device, it is necessary to remove it.

Note! The first is removed negative terminal. However, when installing it connects the latter.

Electrolyte level

Conduct the level and density of the battery solution is recommended for at least once every three months. The level is checked using a glass tube (the inner diameter should be 4-5 mm) through the filler appeals.

The tube should be lowered to the end, the outer prompts must be fine with your finger and remove. The permissible level of electrolyte in the battery must be 12-15 mm.

If there is a tube in the battery, the level may exceed 3-5 mm.

Electrolyte density

The second indicator is the electrolyte density - plays an equally important role, so it is also necessary to control it.

During operation, the density of the liquid can fluctuate full of discharge - Full charge, indicators may vary by 0.15-0.16 units.

The high level of density can cause a rapid wear of the instrument, with a low density level, the engine start will be performed for a long time and problematic.

Battery charge level

To check the charge rate of the car battery, use the load plug. This device has a voltmeter, switch loading resistance, handle and two contacts.

Also, the charge can be determined by repaying from the output voltage, for this you will need a multimeter and a voltmeter (it is important to turn off the minus terminal).

Modern devices are equipped with an indicator showing the battery charge. If the device is charged, the indicator lights green, smashed white or red.

To charge the car battery, you must use the charger, which is the current source: Positive contact attach to plus TerminalNegative - to the minus.

Methods for recovering battery

Each motorist is interested in how to extend the battery life or how to restore it.

And yet, if you missed or ignored some tips regarding the operation of the device, we should not despair, below we will tell you what ways to restore the functioning of this device.

Using CTC

KTC (Training Cycle), this procedure helps to restore the capacity and avoidance of the sulfate process. The CTC procedure consists of several stages of discharge and battery charge.

For this we will need:

- Charger.

- The voltage control device is a voltmeter.

- The device for monitoring the level of electrolyte density is a carometer.

- Light bulb.

So, first fully charge the battery. It is important that while charging a cover with cans were removed. The battery should be charged from 6 to 8 hours.

Upon completion of the procedure using the area, it is necessary to check the electrolyte density level in each bank separately - the indicator should be 1.27 g / cm. cube If necessary, distilled water is added to the banks or sulfuric acid, after which the battery is postponed for another half an hour.

Multiple charging mode

No less simple method Restore the correct operation of the battery, proposed by car specialists, is to conduct several stages of the charge of the device with interruptions. Initially, it is necessary to set the current level to the indicator 0.04 of the nominal battery volume. After 8 hours of charging, you must make a 12-hour break (not more than 16 hours).

The break is necessary for aligning the inner potential and external lead plates, the diffusion of dense electrolyte is performed in the intervals between the electrodes.

After the break, the battery charge procedure is renewed. It is recommended to carry out at least 5 such procedures. During the increase in volume, the level of electrolyte density will increase, as a result of which it must be diluted with distilled water and control the level indicator, it is important to keep it within the normal range.

Chemicals

So, first, you must complete the battery charging device, after which it is important to drain the entire electrolyte. Now it is necessary to wash the container with distilled water, at least three times.

For the next stage of washing, we take a solution of 5% (weight.) Ammonia and 2% (weight) of the trillion V. pour it into the tank pre-purified with distilled water, with which the electrolyte was pulled out and leave for an hour.

The spray and active gas release will be observed, this is the process of desulfation. Upon completion of the gas division, the procedure can be considered complete. Now we drain the liquid from the battery and rinse the container again using distilled water (2-3 times). Now fill the battery with a new electrolyte and spend a complete charge.

If strong sulfate is observed, then the recovery of the battery can be spent a couple of times. However, we note that such a solution cannot be prepared independently, it is recommended to contact a specialist.

Pulsed current

This method will help solve the problem of closure in a battery bank, many do not know about such a method or do not risk it to use, however, according to the reviews of many motorists, it is safe to say that the burning method with a pulmonary current is quite effective.

Connect the battery to the source produced by the high current (in this case it is at least 100 amps). Very often, a welding machine is used with such a goal. The closure in the bank is burned as a result of a two-second passage of this current.