Chrome order at home

Chroming at home is a procedure with which almost every person can cope. Chrome details with your own hands, you can get high-quality coverage for relatively small money.

The chrome of parts is applied to their surface of the thin layer of chromium on their surface. It is possible to apply chromium on the workpiece of steel, copper, aluminum and other metals. The resulting coating not only gives the details a beautiful appearance, but also protects the metal from corrosion and negative environmental influence.

Methods of chrome

Surface treatment makes it possible to get high quality coating that protects the product from chemical and mechanical influence. Complete chrome at home can be three ways.

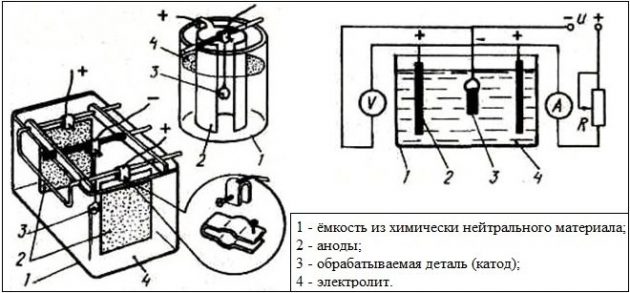

Galvanic

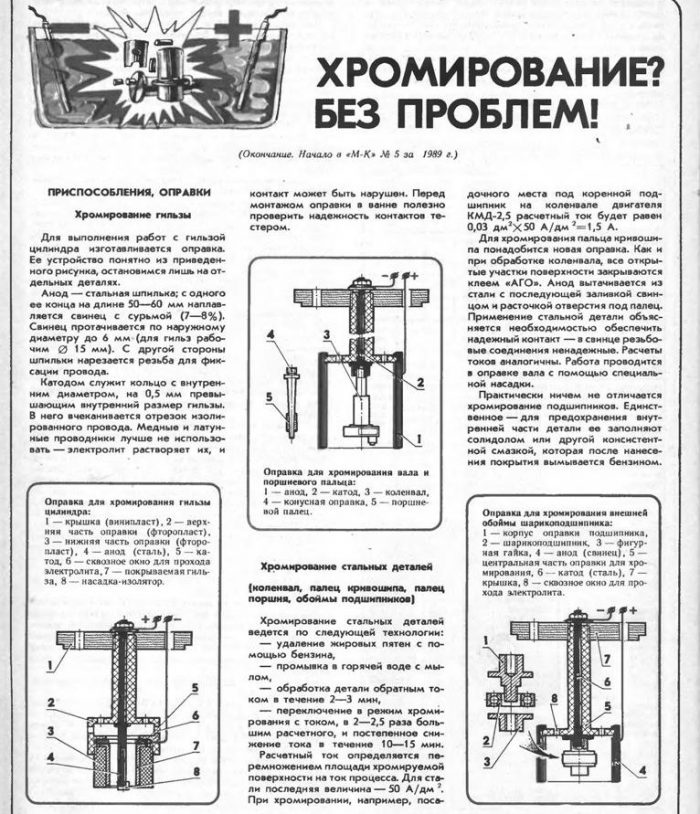

This is the most frequently used method. With a galvanic method, a specialized solution (electrolyte) is created. After placing a metal part into a container with electrolytic solution, a DC voltage is supplied to it and a specialized electrode. Under the influence of electric current, chrome atoms fall on the workpiece.

Chemical

When using this method of applying, a specialized solution from chemical reagents is manufactured. The product is placed in a bath with such a solution. The solution reagents interact with each other, and chrome salts lay on the part. With a chemical method there is no need to apply an electric current.

Reagent solutions are perfectly suitable for chroming parts with small surface damage. After the procedure is completed, it will be necessary to polish the workpiece. The product will acquire glitter only after polishing.

Spraying

To perform the procedure, this method will require a specialized galvanic brush. After making an electrolytic solution for chrome, it is applied on the product with a brush. At the same time, the DC voltage is supplied to the brush and the workpiece. Under the action of current, the chromium atoms from the solution lay on the surface of the product.

Spraying does not require using a bath for immersion parts into a solution. Therefore, in this way it is possible to apply a layer of chromium on the blanks of larger sizes.

Preparation for work

Before starting work, it is necessary to prepare products and necessary equipment. The quality of the coating obtained depends on the correctness of the preparation.

Preparation of the product

To obtain a qualitative and uniform chrome layer, you need to pre-clear the processed surfaces. It will be necessary to remove all the layers of dust, dirt, varnish, paints and rust. This can be done by sandpaper or using sandblasting.

When using sandpaper, it is necessary to remove dust and fine abrasive particles with compressed air. After cleaning, the surface should be equalized. The permissible size of irregularities is no more than one millimeter.

To chrome smoothly, it is necessary to degrease the workpiece. For degreasing, a specialized solution is used, which can be made independently. To create a solution, it is necessary to add 150 grams of sodium hydroxide, 5 g of silicate adhesive and 50 g of calcined soda. The ratio of components is indicated on one liter of water. After creating a solution, it is heated to 90 degrees and give it a product.

Preparation of electrolyte

Electrolite should be prepared for galvanic chromium. Its components are chromic anhydride, sulfuric acid and water. The preparation of the electrolyte to work is as follows:

- A distilled or boiled water is poured into hermetic non-metallic tank. Capacity should be filled with half.

- Water is heated to a temperature of 55 - 65 degrees.

- Anhydride chromium is added at the rate of 250 grams per liter of water

- Sulfuric acid is poured from the calculation of 2.5 grams per liter.

- After mixing through the electrolyte, the DC voltage is supplied for 3 hours. The current is 6.5 amp per liter.

- After purchasing a brown solution, it must be put in a cool place for 24 hours.

Preparation of equipment

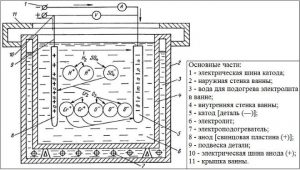

To obtain a galvanic coating, it will takes the use of the following equipment:

- Container for setting capacity. Suitable bin made of wood. The walls and the bottom of the box should be inspired by creating the effect of the thermos.

- Capacity required size. Capacity should be glass. The usual three-liter bank is suitable.

- Electric heating element. A ceramic tan is used.

- Thermometer to which liquid temperature can be measured to 100 o C.

- Non-metallic capacitance cap. It should herddle close the vessel. As a material for the lid, you can use Fane.

- DC source.

- Electrodes. The inner anode is made of lead plate. The cathode is the processed product.

- Wires for connecting.

When chrome, evaporation is allocated, negatively affecting human health. You should purchase personal protective equipment.

Chrome holding

The chromeration procedure is as follows:

- The electrolytic solution in the container is heated to 53 degrees;

- The processed part is fastened on the wire using a special clamp and falls into the electrolyte;

- After the temperature of the workpiece and the solution becomes approximately equal, the DC voltage is supplied to the anode and the cathode;

- After the process is completed, the part is heated in the furnace for 2.5 to 3 hours. This makes the coating obtained during chromium.

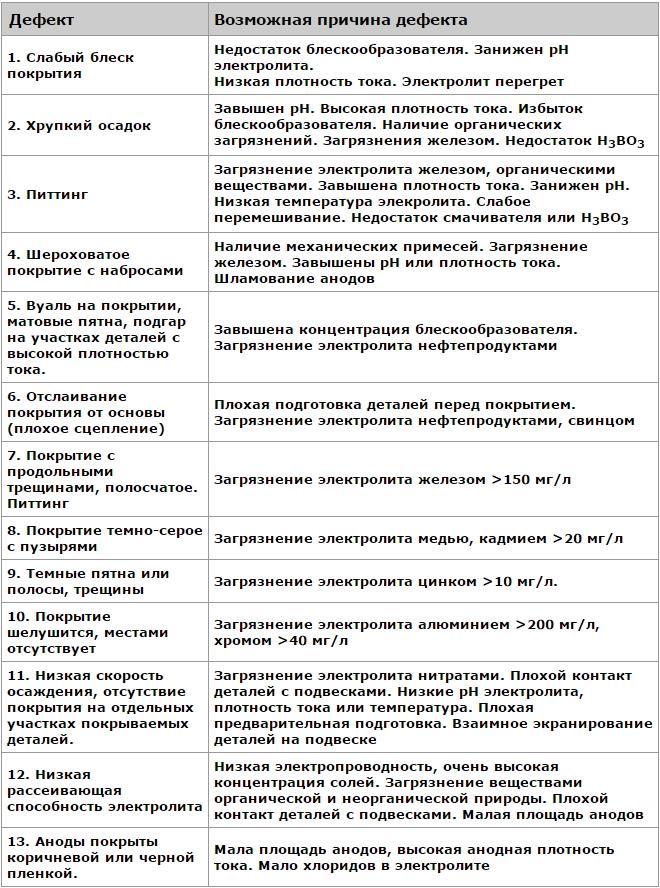

Causes of coating defects

There are several defects:

- Uneven shine - Too much current or low temperature temperature.

- Lack of brilliance - Insufficient amount of sulfuric acid or anhydride.

- The appearance of brown spots - Lack of sulfuric acid or excess chromium anhydride.

- Low coating strength - Low strength of the current or overestimated electrolyte temperature.

Scope of technology

Chromeing is used to improve the appearance of worn out parts of cars, motorcycles, etc. It is used to create products, the surface of which requires a special shine. Chromium applying protects parts from corrosion and mechanical damage.

From the above it follows that anyone can perform chrome of metal parts at home. To obtain a high-quality layer, it is necessary to strictly adhere to certain instructions.