Why is the rear axle gearbox humming on the VAZ 2107 and Niva?

A considerable number of owners of classic Zhiguli cars wondered why the rear axle gearbox of the VAZ 2107 and previous models was humming. This unit was expensive at all times, and it is almost impossible to repair it yourself. When the rear of a car howls, all that remains is to clearly diagnose the problem and contact a good technician. And also understand the cause of the breakdown in order to avoid a repetition of the situation in the future.

Causes of malfunction

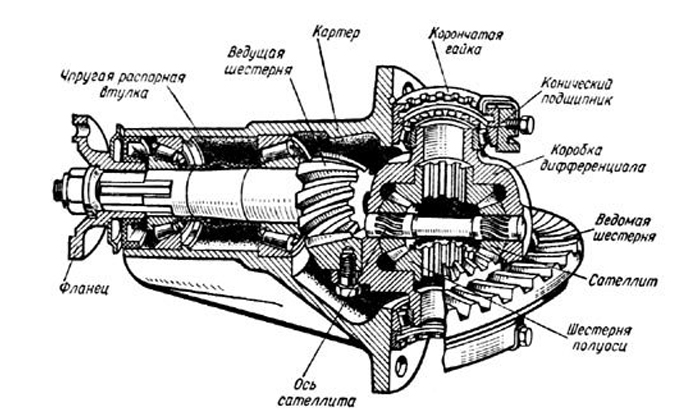

The VAZ 2107 rear axle gearbox is a complex and precise mechanism with a high degree of reliability. Nevertheless, for one car enthusiast it lasts the entire “life” of the car without the slightest problem, while another changes the gearboxes one after another, but the result is still the same. Based on practical observations, it is worth highlighting several reasons for the breakdown of the unit:

- operation of VAZ 2101-07 in extreme mode with overload;

- frequent slipping when moving from a stop;

- strong jerks when towing another car;

- loss of oil and dry driving;

- intervention of incompetent “masters”.

Driving with a heavy load means driving with an overloaded trailer and car. For such car enthusiasts, gearboxes fail very often. The same can be said about extreme sports enthusiasts who love to drive off to the sound of squealing tires. After such loads, the unit can howl at any moment.

The hum of the rear axle gearbox may occur after towing another car, when it needs to be pulled out of some hole or mud. For this reason, the mechanism on the Niva often suffers among fans of extreme off-road driving.

Loss of oil from the rear axle housing can occur for the following reasons:

- mechanical damage to the crankcase or “stocking”;

- failure of the oil seal on the shank or axle shaft plus the owner’s inattention to this problem;

- incompetent disassembly of any of the rear hubs when oil leaks from a skewed beam.

Separately, it is worth mentioning the actions of some “specialists” who interfere with the operation of the unit. A simple example: when replacing a crosspiece, a car mechanic discovers that the nut on the shank is loose, and tightens it with a wrench, but more firmly. As a result, the bearing is clamped to the limit, the spacer sleeve is deformed and wear appears on the teeth of the working pair, causing the rear axle to hum.

A humming sound coming from the gearbox can be caused by the addition of various additives to the lubricant of the unit. It is also possible to predict the occurrence of a hum when using oils that do not comply with the manufacturer’s recommendations.

As a rule, in 99 cases out of 100, a “sounding” unit must be repaired with the replacement of the main working pair of gears; it will not be possible to get by with “little loss.”

Diagnostics of the mechanism by sound

It is very important to catch the moment when the gearbox just begins to hum. Then there is a chance to save a little on repairs. Usually, when the main pair is exhausted, the howl begins to appear at a speed of 60-80 km/h. If you do not pay attention to it, the hum will spread over a wider range of speeds and will become audible already at 40 km/h. Completely neglected units begin to hum at 20 km/h, and at a speed of 80-100 km/h it is impossible to even talk inside the car.

Experts recognize the following types of humming sounds from the rear axle:

- The howl is heard only when driving “under load”, that is, when the accelerator pedal is pressed. If you release it, the sound disappears.

- Constant hum that only stops when the car stops.

- Crunching sounds. Their frequency depends on the speed of the vehicle.

- "The trolleybus effect." A howl, similar to the noise of an approaching trolleybus, occurs only when the accelerator pedal is released, provided that some speed is turned on. If you coast in the neutral position of the gearbox, the sound becomes much quieter, but does not disappear completely.

A whine under load indicates that wear has appeared on the gear teeth. At the initial stage, good craftsmen sometimes manage to eliminate the malfunction with adjustments, but this does not last long. You should prepare to replace the shank and planetary gear. An incessant whine indicates wear on the shank bearings. If they are not changed in a timely manner, production will appear on the main steam.

Crunching noises are produced by worn differential bearings, and the “trolleybus” appears due to a loose or completely unscrewed nut on the shank. This malfunction is especially dangerous, since if the nut is unscrewed, the teeth of the drive gear can break at any time. Therefore, it must be eliminated immediately, otherwise the broken teeth may jam the entire mechanism.

Clarifying the diagnosis

Many motorists, out of ignorance, confuse noise from the gearbox with other faults, and then begin to change completely working parts. Often they are helped in this by garage “masters” who are incompetent in the work of gearboxes. Following their advice, the owner of a VAZ 2106 can pour some additive into the crankcase of a working gearbox, which will disable it. This cannot be done; additives will not restore a humming unit, but they can ruin a working one.

To make an accurate diagnosis, you need to check the following points:

- make sure there is lubricant in the crankcase;

- check if the seals are leaking;

- measure the amount of play in the mechanism.

The backlash is determined by freely turning the cardan manually and placing marks on it and the gearbox housing. The ideal backlash is 2-3 mm, acceptable - 10 mm.

In order not to confuse the noise from the gearbox with the hum of axle bearings or the crunching of crosspieces, it is recommended to perform an on-site hearing test. To do this, you need to, together with an assistant, hang the rear of the car so that both wheels do not touch the ground. After starting the engine, turn on the gear and listen in different modes to where the sound source is. The procedure is performed on an inspection ditch or lift.