Crankshaft sensor - signs of malfunction of this important vehicle

One of the most important assemblies of the modern car is the DPKV - the crankshaft position sensor, the signs of the malfunction of which signals the driver about the need for urgent repair of this unit. Such an immediate repair is really needed, as it will stop without it.

What is a DPKV

Before finding out how to determine the problem of the crankshaft sensor, also called the alarm indicator, should be declaring that it represents and for which it is intended. This node enables the vehicle fuel injection system to perform the synchronous functioning of fuel injectors and.

Its device is completely simple: the kapron frame, wrapped with copper wire, is attached on the steel core. The wire is enhanced by enamel, the role of the sealant performs the compute resin. During operation, the sensor sends the signals of the ECU on operation and position.

A malfunction deprives the CU system of the possibility to establish a number of important characteristics - the amount of injected fuel and the injection itself, the corner of the camshaft, the fact of ignition (gasoline engines) and others. That is why it is so important to know how to check the health of the crankshaft sensor, if you do not want to get stuck somewhere on a deserted road because of the engine stroke.

Crankshaft sensor - fault signs

The following crankshaft sensor malfunction symptoms are available for the driver:

- tangible detonation in the motor at dynamic load;

- turns with signs of instability at idle;

- reduction of engine power, noticeable without instrument readings;

- a significant reduction during the ride of the car dynamics - a clear symptom, which, however, can signal and about any other problems with the engine;

- the revs are incontrolled incomprehensively either downward.

Also evidence that the crankshaft position sensor is defective, it is a banal inability to start the auto motor. Thus, you do not need to be a superprofessional in the issues of the device of electronic circuit circuits to identify signs of the crankshaft position sensor fault.

How to check the crankshaft position sensor

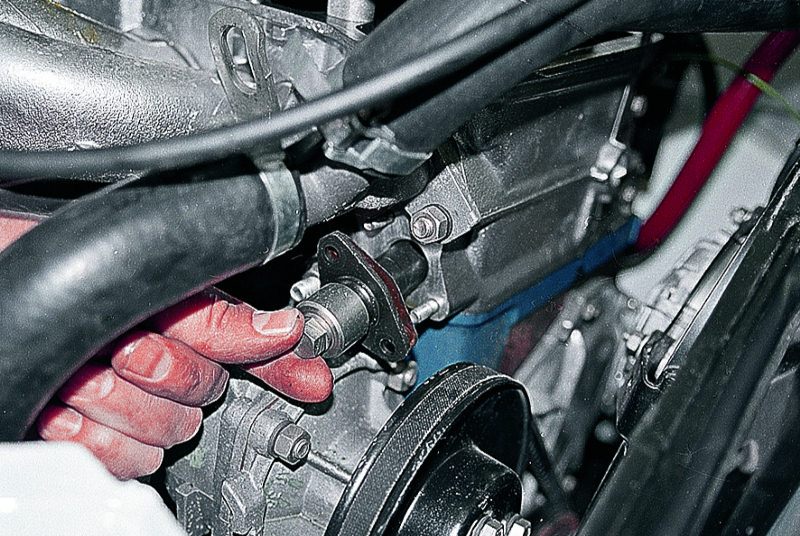

The performance of this node can be analyzed in several ways. You only need to stock up the necessary devices, remove the synchronization sensor from the engine, inspect it and proceed directly to check. Note that with an external inspection it is possible to establish certain damage to the contact pad, core or DPKV housing. Sometimes elementary cleaning of cores and contacts from pollution solves all problems. If the explicit defects of the unit are not detected, the "hidden threats" check should be started.

How to ring the crankshaft sensor by the mel

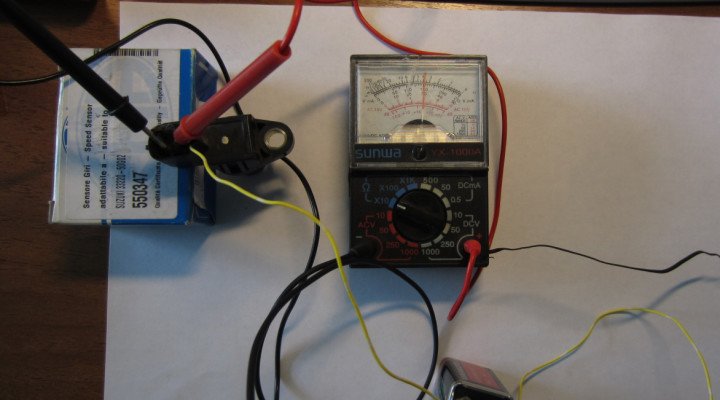

This, honestly, the elementary option makes it easy to solve the problem of how to check the crankshaft position sensor for service. Ommeter you just need to measure the resistance of the DPKV winding. For most vehicles, its normal value varies from 550 to 750 ohms.

The second method of checking

It is more complicated, involves the application:

- ommeter and megaommeter for measuring resistance (as indicated earlier);

- inductor meter, normal indicator - from 200 to 400 MHz;

- digital voltmeter (it is allowed to use a regular device) and a network transformer.

The result of measurements give a unambiguous response about whether the crankshaft position sensor is limited or faulty.