Motor Diagram VAZ-2114 Engine Injector 8 Valves

To independently repair the VAZ-2114 with an 8 valve injector, you need to know the device and the engine performance principle. Possessing these knowledge, you can set the cause of the fault without resorting to assistance.

On the VAZ series engines installed a fuel injection system that allows you to improve the ride rate, and it is characteristic of a decrease in the percentage of toxins in the exhaust gases. There are two types of fuel injection systems: with feedback, as well as without it, they may differ in details. It all depends on the export or import of products.

The feedback of the injection is usually used in models of machines supplied abroad, and is equipped with a neutralizer. In the system without feedback (sold within the country), a co-potentiometer is mounted, which performs adjusting the exhaust gases.

Neutralizer

To change the toxic elements and transform them into the components without toxins, the car is equipped with a neutralizer. Its location is an exhaust system, directly behind the silencer pipe.

For the qualitative functioning of this unit, it is necessary that the mixture supplied to the engine contains a certain proportion of air and fuel. This is due to the electronic injection system, which controls the distribution of fuel based on the efficiency of the load on the engine.

Electronic control unit

This unit controls the information coming from the sensors, and is responsible for managing the fuel injection system.

In the control unit there is a diagnostic system, due to which the system fails is recognized. It signals all the problems occurring in the system through a light bulb located on the dashboard - Check Engine. It also saves all the errors ever. Subsequently, their codes help to figure out when diagnosing problems.

Memory

The ECU contains three types of memory. RAM is a kind of notebook. All temporary data is made to it. The microprocessor of RAM is located on the board of the ECU. To preserve all incoming information, it needs to be in uninterrupted voltage intake.

ROM is an energetically independent memory that saves all the data. The sequence of all the actions performed is fixed in the PPZ.

Sensors

The temperature sensor is a small thermostat in the cylinder head pipe, with its help the temperature indicator of Tosol occurs.

The temperature sensor is a small thermostat in the cylinder head pipe, with its help the temperature indicator of Tosol occurs.

The detonation sensor is screwed into the cylinder block and fixes the detonating phenomena occurring in the motor. In the event of the appearance of the slightest vibration in the motor, the pulse is transmitted to it. After that, in the signal coming from the control unit, the ignition is adjusted, during which unwanted fuel flashes are eliminated, leading to the appearance of detonation.

Oxygen level sensor is installed in a feedback system. His fastening site is in front of the muffler. The normal temperature indicator reaches 360 degrees, and for active warming of the motor, a special heating element is provided.

Air flow sensor is attached not far from the air filter. It consists of three elements, one of them determines the ambient temperature, the remaining is needed to maintain a certain temperature level exceeding the figure of the first. The air flow cools all the heating elements, and the ECU applies this information to determine the air flow and sets the duration of the opening or closing of the nozzles.

The location of the co-potentiometer - the engine compartment (the wall of the air inflow box). This element gives a signal to the ECU used to adjust the desired proportion of air and fuel.

The vehicle determination sensor is located near the engine oil level. Through it is given a signal to the ECU similar speed of leading wheels.

Sync sensor - located on the oil pump covers near the pulley of the generator drive. According to information coming from it, the control unit calculates the crankshaft rotation frequency and then supplies the characteristic signal to the nozzles.

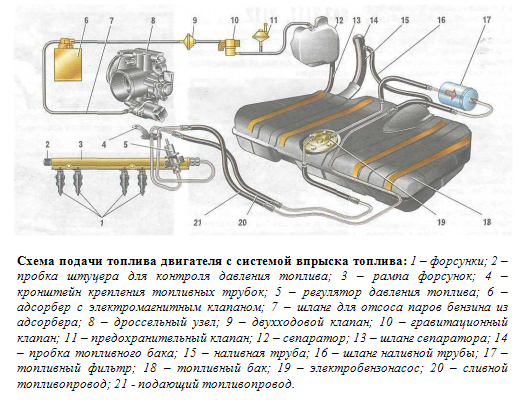

Supply system

The air filter is placed in the front of the motor and is equipped with fixing elements from rubber. If you need to replace them, the corrugation is located on one parallel with the axial line of the car. The main function of the throttle nozzle is determined by the dosing of the air flow entering the inlet tube. The air falling into the engine is adjusted due to the throttle, which is connected to the accelerator pedal. The throttle nozzle consists of two components: the throttle position sensor and idle regulator.

The air filter is placed in the front of the motor and is equipped with fixing elements from rubber. If you need to replace them, the corrugation is located on one parallel with the axial line of the car. The main function of the throttle nozzle is determined by the dosing of the air flow entering the inlet tube. The air falling into the engine is adjusted due to the throttle, which is connected to the accelerator pedal. The throttle nozzle consists of two components: the throttle position sensor and idle regulator.