Symptoms of a mass flow sensor fault

Managing the operation of the automotive engine, the electronic unit acts according to the indications of the group of main sensors. This includes a meter for the amount of air absorbed by the intake manifold through an open throttle. Having obtained this data, the controller increases or reduces the supply of fuel, achieving the optimal ratio of combustible mixture components. The yield of the flow meter is notably worsens the operation of the power unit up to the impossibility of further movement. Therefore, novice drivers are desirable to study signs of a mass flow sensor fault (abbreviated DMRV).

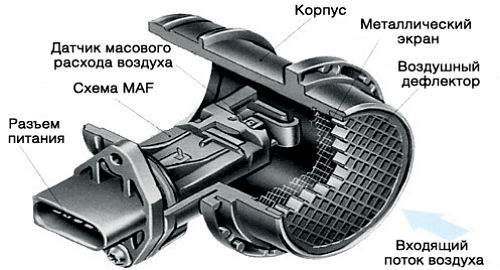

Flow meter design

Knowing the air sensor device, you quickly understand the principle of its work and understand why the defective meter is not repairable, but only replacement. It is not difficult to find the device - it is built into the air duct connecting the filter - the air flow cleaner with the throttle block. The exact location depends on the brand and auto model.

Most of the operating cars are installed thermoelectric or film meters. The difference in the design of the sensing element, the principle of operation remains unchanged. Anneometric flow meter is a housing where 2 platinum threads are placed - measuring and reference. How the DMRV functions in the car:

- The controller serves meals on both threads. Heating, they equally change resistance.

- With the engine running, the first thread is washed by air passing through choke and cooled. The stronger the air flow, the more intense cooling.

- The electronic unit records the resistance difference on the measuring and reference thread. By computing, the ECU determines the mass of the passing air and directs the corresponding amount of fuel to the nozzles.

Reference. In modern cars with turbochargers, mass flow sensors are replaced with absolute pressure meters (DDA) - more reliable devices with a long service life. Similar products manufacturers have begun to equip new atmospheric engines.

The film measuring device is valid for the same principle, only instead of the threads are used ceramic elements with platinum spraying. That is why check out the DMRV is quite possible, to repair - it is impossible. Disturbing thread or damaged coating will not be replaced, only the product is entirely.

The effects of the sensor breakdown

When, due to different reasons, the sensor fails or issues incorrect readings, the controller changes the work algorithm. It begins to prepare the fuel-air mixture, focusing on the meter of the position of the throttle valve and lambda - probe. Due to the lack of data arrived earlier from DMRV, the electronic unit "does not know" about the real number of incoming air and cannot mix it with gasoline in optimal proportions.

Thanks to the transition of the controller on the emergency operation, you can determine the main symptoms of the DMRV fault:

- on the driver's dashboard, the control unit includes a Check Engine lighting board, indicating problems in the fuel supply system or ignition;

- idling is unstable - it rises to 1500 rpm, it drops to zero (the engine stalls);

- "On the cold" motor will start with great difficulty;

- the incorrect preparation of a combustible mixture causes an increase in fuel consumption regardless of driving conditions and operating mode;

- there is a decrease in the power of the power unit and frequent undue jerks on the go.

Note. Enable the Check Engine indicator does not give the driver of specific data on the nature of the breakdown. The inscription encourages diagnose the engine system using a computer connected to the service port. In this way, you can check the efficiency of DMRV and other sensors in the maintenance station.

Indirectly on the fault of the flow meter indicates the appearance of black smoke from the exhaust pipe. If there is no on-board computer on the vehicle and track the instant gasoline consumption is impossible, it is worth unscrewing 1-2 candles from any cylinders and inspect the electrodes. The black soot layer will confirm the excessive enrichment of the mixture due to the emergency mode of operation of the electronics.

If the motorist does not respond to the above problems and continues the operation of the machine, then he will have to face larger troubles. The permanent overlap of the fuel mixture will quickly lead into disrepair of the spark plug, the combustion quality will deteriorate, the load on the cylindrophneum group will increase, and wear will increase significantly. The perspective is dark - repair of the power unit.

If the motorist does not respond to the above problems and continues the operation of the machine, then he will have to face larger troubles. The permanent overlap of the fuel mixture will quickly lead into disrepair of the spark plug, the combustion quality will deteriorate, the load on the cylindrophneum group will increase, and wear will increase significantly. The perspective is dark - repair of the power unit.

Causes of trouble

The air flow meter comes into disrepair for the following reasons:

- a lot of dust and dirt fall on the measuring elements, because the owner of the car rarely changes the air filter;

- on highly worn engines, the pairs of gasoline and oil penetrate into the DMRV through the crankcase ventilation pipe;

- the hole in the corrugated air duct, where dust is absorbed;

- random damage due to unqualified repair;

- cutting the wire connecting the sensor connector with the controller.

In addition to the listed causes, the natural wear of the device is also found. The resource of the new DMRV is 50-250 thousand km depending on the brand and origin of the car.

Diagnosis in garage conditions

The above symptoms are also manifested with other damage, for example, the output of the oxygen sensor or the throttle position. In all such cases, the electronic unit acts the same - enters the emergency mode of preparation of air-gasoline mixture. Hence similar consequences.

To check the air consumption sensor without instruments, perform a number of simple actions:

- Open the hood and disconnect the DMRV connector.

- Get the engine and track the work at idle. The controller should raise the crankshaft turnover to 1500 rpm and hold them stably. If idling continues to "swim", the flow meter is most likely in charge.

- Make a checkline for a short distance, watching the behavior of the car. If the motor started working even worse, then the problem lies elsewhere.

A similar technique does not allow you to accurately determine the "culprit" of problems, especially when there are several. For example, parallel lambda failed. It is necessary to carry out more accurate diagnostics - check the DMRV multimeter according to the following instructions:

- Switch the multimeter to the voltage measurement mode. Open the hood and find the sensor connection block.

- Connect the red wire from the device to the contact of the incoming signal (usually painted with yellow). Second clamp with black insulation Connect to a green conductor.

- Turn on the ignition and fix the voltmeter readings.

Voltage in the range of 1-1.03 V indicates the full performance of the sensor. If when driving a car, signs of emergency regime are monitored, it is worth checking the remaining meters affecting the fuel feed.

Voltage in the range of 1-1.03 V indicates the full performance of the sensor. If when driving a car, signs of emergency regime are monitored, it is worth checking the remaining meters affecting the fuel feed.

The readings 1.04-1.05 volts suggest that the platinum elements of the sensor are decently worn, it should be prepared for the replacement of DMRV. The value of 1.06 V and more testifies that the air flow meter ordered to live long. You need to purchase a new meter and install it on the air duct instead of the old one.

If, as a result of the diagnostics, you received the average indicators, the sensor does not prevent clearance. Do not try to penetrate into the DMRV various brushes - for this purpose there is a special liquid, flushing the dirt from the air grid and measuring elements.