How does the internal combustion engine

For a real motorist, the car is not easy to means of movement, and also a tool of freedom. With the help of a car, you can get anywhere in the city, country or continent. But the availability of rights for the real traveler is not enough. After all, there are still many places where it does not catch a mobile, and where evacuators cannot get there. In such cases, with a breakdown, all responsibility falls on the shoulders of the motorist.

Therefore, every driver should at least understand the device of his car, and you need to start with the engine. Of course, modern automotive companies produce many cars with different types of engines, but most often manufacturers in structures use internal combustion engines. They have a high efficiency and at the same time provide high reliability of the entire system.

Attention! In most scientific articles, internal combustion engines are abbreviated by the DVS.

What are the economy

Before proceeding with a detailed study of the DVS device and their principle of work, consider what the internal combustion engines are. Immediately need to make one important remark. For more than 100 years of evolution, many types of structures were invented by scientists, each of which has its own advantages. Therefore, to begin withdrawing the main criteria for which these mechanisms can be distinguished:

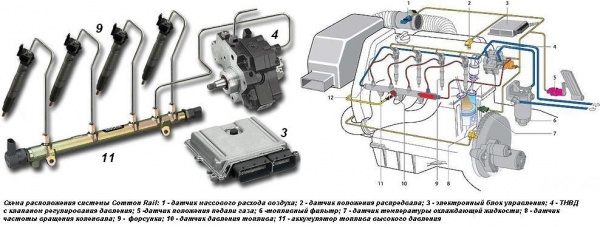

- Depending on the method of creating a combustible mixture, all ICEs are divided into carburetor, gas and injection devices. And this is a class with external mixture formation. If we talk about internal, then it is diesel engines.

- Depending on the type of fuel, the engine can be divided into gasoline, gas and diesel.

- Cooling the devices of the engines can be of two types: liquid and air.

- Cylinders can be located both in opposite each other and in the form of the letter V.

- The mixture inside the cylinders can ignite the spark. This happens in carburetor and injection engine or at the expense of self-ignition.

In most automotive magazines and among professional autoexports, it is customary to classify the DVS, on such types:

- Gas engine. This device works at the expense of gasoline. The ignition is forcibly with the help of a spark that the candle generates. Carburetor and injection systems are responsible for the dosage of the fuel and air mixture. Inflammation occurs when compressed.

- Diesel . Engines with a device of this type operate due to the combustion of diesel fuel. The main difference in comparison with gasoline aggregates is that fuel is exploded due to the increase in air temperature. The latter becomes possible due to the growth of pressure inside the cylinder.

- Gas systems function using propane-butane. Ignition occurs forcedly.Gas with air is supplied to the cylinder. Otherwise, the device of such a DVS is similar to a gasoline motor.

It is such a classification that is most often used, indicating the specific features of the system.

Device and principle of operation

Internal combustion engine device

It is best to consider the DVS device on the example of a single-cylinder engine. The main part in the mechanism is the cylinder. It is piston in it, which moves up and down. In this case, there are two control points of its movement: upper and lower. In professional literature, they are referred to as NMT and NMT. Decoding Next: Upper and lower dead dots.

Attention! The piston is also connected to the shaft. The connecting link serves the connecting rod.

The main task of the connecting rod is the conversion of energy that is formed as a result of the movement of the piston up-down into the rotational. The result of such a transformation is the movement of the car into the direction you need. It is for this that the device of the engine is responsible. Also, do not forget about the on-board network, the work of which becomes possible due to the energy generated by the engine.

The flywheel is attached to the end of the DVS shaft. It provides the stability of the rotation of the crankshaft. The intake and exhaust valves are at the top of the cylinder, which, in turn, is covered with a special head.

Attention! Valves open and close the corresponding channels at the right time.

So that the DVS valves opened, camshaft camshaft are affected. This happens by means of gear stations. The shaft itself moves with the crankshaft gear.

Attention! The piston is freely moving inside the cylinder, frozen on a moment, then in the upper dead point, then in the bottom.

In order for the DVS device in normal mode, the combustible mixture should be fed into a clearly verified proportion. Otherwise, fire may not happen. A huge role also plays the moment in which the feed occurs.

The oil is necessary in order to prevent premature wear of parts in the DVS device. In general, the entire device of the internal combustion engine consists of such main elements:

- ignition candles

- valves

- pistons

- piston rings

- rods

- crankshaft

- carter.

The interaction of these system elements allows the DVS device to produce the energy desired to move the car.

Principle of operation

Consider how the four-stroke engine works. To understand the principle of his work, you should know the meaning of the concept of tact. This is a certain period of time for which the device is required inside the cylinder inside the cylinder. It can be compression or ignition.

The wf cycles form a working cycle, which, in turn, provides the operation of the entire system. In the course of this cycle, thermal energy is converted into mechanical. Due to this, the movement of the crankshaft.

Attention! The working cycle is considered completed after the crankshaft will make one turn. But such a statement only works for a two-stroke engine.

Here you need to make one important explanation. Now the device of the four-stroke engine is mostly used in cars. Such systems are characterized by greater reliability and improved performance.

To perform the four-stroke cycle, two crankshaft turns are needed. These are four piston movements up-down. Each beat performs actions in the exact sequence:

- inlet,

- compression,

- expansion,

- release.

The penultimate tact is also called a workforce.About the upper and lower dead dots you already know. But the distance between them indicates another important parameter. Namely, the volume of DVS. It can fluctuate on average from 1.5 to 2.5 liters. The indicator is measured by hanging the data of each cylinder.

During the first half-timer, the piston with the NMT moves to NMT. At the same time, the intake valve remains open, in turn, the graduation is tightly closed. As a result of this process, discharge is formed in the cylinder.

The combustible mixture of gasoline and air falls into the Gas Pipeline of the DVS. It is mixed with exhaust gases. As a result, an ideal substance is formed to ignite, which is amenable to compression on the second act.

Compression occurs when the cylinder is completely filled with a working mixture. The crankshaft continues its turnover, and the piston moves from the bottom dead point in the upper one.

Attention! With a decrease in volume, the temperature of the mixture inside the CBO Cylinder is growing.

On the third tact there is an extension. When compression comes to its logical conclusion, the candle generates a spark and igniteness occurs. In the diesel engine, everything happens a little differently.

First, instead of the candle, a special nozzle is installed, which on the third clock injected fuel into the system. Secondly, air is injected into the cylinder, and not a mixture of gases.

The principle of operation of diesel engine is interesting in that it is flavored in it independently. This is due to the increase in air temperature inside the cylinder. Such a result is possible to achieve due to compression, as a result of which the pressure is growing and the temperature rises.

When the fuel through the nozzle falls inside the cylinder of the internal combustion engine, the temperature inside is so high that the ignition comes by itself. When using gasoline, it is impossible to achieve this result. All because it flammives with a much higher temperature.

Attention! In the process of the movement of the piston from the micro-sized engine, the DVS detail makes the return jerk, and the crankshaft scrolls.

The last beat in the four-stroke engine is the name of the inlet. It occurs on the fourth seven. The principle of its action is quite simple. The outlet valve opens, and all combustion products fall into it, from where to the exhaust gas pipeline.

Before getting into the atmosphere, spent gases from Usually pass the filter system. This allows you to minimize the damage caused by ecology. Nevertheless, the device of diesel engines is still much more environmentally friendly than gasoline.

Devices that allow you to increase the performance of the engine

Since the invention of the invention, the first FEF system is constantly being improved. If you remember the first serial car engines, they could accelerate a maximum of 50 miles per hour. Modern supercars are easily overcome the mark of 390 kilometers. Such results managed to achieve a scientist at the expense of integration into the device of the engine of additional systems and some structural changes.

A large increase in power in its time gave the valve mechanism embedded in ICA. Another step of evolution was the location of the camshaft at the top of the design. This made it possible to reduce the number of moving elements and increase productivity.

Also can not be denied the usefulness of the modern ignition system. It provides the highest possible stability of work. Initially, a charge that enters the distributor is generated, and from it to one of the candles.

Attention! Of course, you can not forget about the cooling system consisting of a radiator and pump. Due to her, it is possible to prevent timely overheating of the DVS device.

RESULTS

As you can see, the device of the internal combustion engine does not represent a special complexity. In order to understand it, you do not need any special knowledge - quite simple desire. Nevertheless, knowledge of the principles of operation of the OBS will not be superfluous for each driver.