Parking brake system auto and its maintenance

Each car has a brake system divided into two components - workers and parking brakes. The first provides slowdown and stop the car while driving. The second excludes the unauthorized movement of the car after it is put on the parking lot. In this case, the parking brake should ensure the fixedness of the car not only on a flat surface, but also on the slopes and lines.

Working brake mechanisms on passenger cars usually have a hydraulic drive, the main working element of which is. This type of drive provides fast transmission of the effort that creates a driver on a pedal to brake mechanisms. In this case, this drive allows the use of amplifiers that increase the force in the drive. But it is impossible to use hydraulic drive as a parking system.

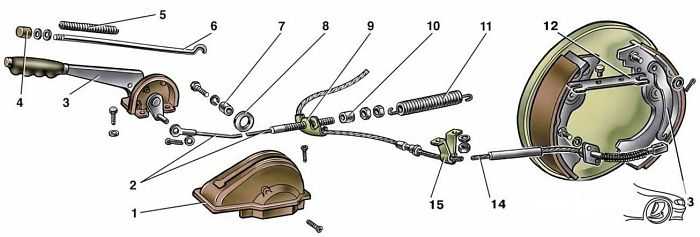

Details of the actuator of the parking brake VAZ 2105:

1 - case; 2 - front cable; 3 - lever; 4 - button; 5 - spring spring; 6 - Latching; 7 - sleeve; 8 - roller; 9 - rear cable guide; 10 - spacer sleeve; 11 - exhaust spring; 12 - spacer plank; 13 - manual lever pads; 14 - rear cable; 15 - Bracket fastening rear cable

The largest distribution on passenger cars has received a mechanical parking brake, as a drive of which metal cables perform. The device of this type of brake is sufficiently simple: a lever, which is connected to the drive cable. In turn, interacts with the brake mechanisms of the back of the wheels of the car, in the design of which special levers affecting on.

Everything works like this: the driver pulls the lever, and with it and the cable. The latter acts on the levers in the brake mechanisms and they connect the brake pads, pressing them to the brake drum. Due to this wheel, the car cannot rotate and the car is immobilized.

In order for when setting to the handbrake, the lever was not returned to its original position on it the ratchet mechanism consisting of a gear sector and the retainer. When pulling the lever, the retainer is among the teeth, preventing a self-voltage refund.

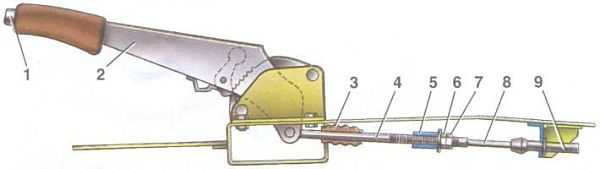

Driving parking brake system VAZ 2108, VAZ 2109, VAZ 21099:

1 - Manual brake lever fixation button;

2 - parking brake drive lever;

3 - protective case;

4 - traction;

5 - cable equalizer;

6 - adjusting nut;

7 - lock nut;

8 - cable;

9 - cable shell

To remove the car from the handbrake, the driver presses on the special key on the lever, thereby pressing the retainer, and the lever may return to its original position. The cable is delayed in place at the expense of springs. At the same time, it affects the levers in the mechanisms and those stop.

Significant distribution mechanical handbrake received due to the simplicity of design and reliability. Even with the refusal of the working brake, there is always the opportunity to stop the car, because the handbrake has its own drive, and completely independent of the other components of the car braking system.

Other types of parking brakes

There are several more types of parking brakes.

- The first, so-called is central, applied on cars equipped with automatic transmission. The essence of such a brake is reduced to the fact that when the PPC selector is transmitted to the "Parking" position, the drive shafts of the wheels are blocked. But it is worth noting that the central brake is only auxiliary, from the mechanism that ensures the blocking of the wheels, they did not refuse and it is present in the design of the brake system.

- The second type of machine brake is an electromechanical. In contrast to the cable, this type is not available as such a drive on the wheel lock mechanism, but there are electric motors that affect the levers in the brake mechanisms. That is, the driver simply presses the key and the electric motors block the wheels. Everything is simple, but not as securely like a cable.

Since the mechanical handbrake is the most common, in the future it will be considered. And start directly from the drive itself. And we consider it on the example of the VAZ-2109.

Most often, by car, the handbrake drive consists of a central cable, the equalizer, or as it is also called - the rocker, and two side cables. The central is connected by one end with a lever in the cabin, and the other with a rocker. But on the VAZ-2109 instead of the central cable, the thrust is used, at the end of which there is a thread for adjusting the tension. At the ends of the side cables are made by the terminats, which they engage in the rocker on the one hand, and the wheel lock levers - on the other.

Major faults

Despite its simplicity and reliability, the hand-made brake needs periodic inspection and maintenance. The fact is that over time the drive is somewhat stretched, because of which it is no longer able to provide full blocking of the wheels.

Such a malfunction may also occur as the casing of the braid. It happens often because of rarely using the handbrake. Since the entire drive passes under the car, moisture and dirt fall inside the braid, leading to metal corrosion. Because of this, the cable is difficult to move. In particularly launched cases, it can boot at all inside the braid.

Corrosion can lead to overjudation of the filament of the cable, which is why it "flies" and the ends of these threads cling to the braid, making it difficult to move. If you do not pay attention to the drive status, ultimately, the cables can be completely overwritten and the parking brake will stop fully functional.

Check and adjust the parking brake

Adjusting manual brake

Checking the efficiency of the parking brake on the VAZ-2109 as in any other car must be carried out about once every 30 thousand km of run. And it is not difficult to perform it. You can put a car on the descent or climb, drown out the motor and pull out the handbrake. If the car will remain on the spot and the unauthorized movement there is no movement, then you can continue to continue the operation of the machine.

Another method of checking is carried out like this: Auto put on the site, the speed is turned off and the handbrake is delayed. After that, you need to turn on the first gear and try to touch. If the machine is slightly shifted from space before the motor stalls, it means that the tension of the cables is needed.

Video: Adjusting the manual brake of the Niva. Ourselves stretch the cable of manual brake Niva

On the VAZ-2109 it is done like this:

- the car rushes onto the flight, pit, or in the extreme case, ponds the back of the car and put on the stops, the lever of the manual brake must be completely lowering down;

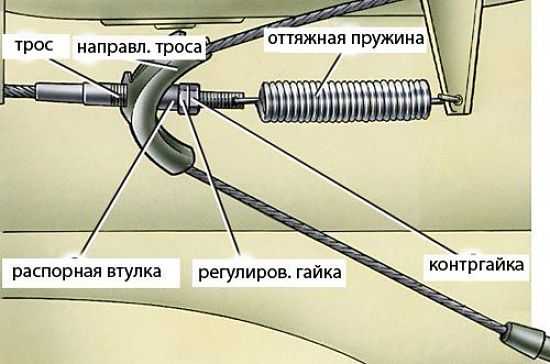

- under the car in the tunnel, it is necessary to find the rocker from which the central thrust with two nuts - adjusting and locking. With the help of two keys weakened lock nut;

- the adjusting nut is screwed to the thread of the thrust until the cables are stretched. After that, the course of the lever is checked until it stops, in a normal adjusted, it must be 2-4 clicks of the ratchet;

- after that, the adjusting nut is fixed with locknut and checking the efficiency of the parking brake.

The design algorithm described by the packer stretch is suitable for almost any car, which uses a mechanical handbrake. The difference only comes down to some constructive features.

Grease, replacement

Video: how to lubricate the handbrake cable

If the manual brake does not work due to the scope of the cables, you can try to lubricate and develop them. But for this you will have to remove them with the car. On VAZ-2109 it is done like this:

- the back of the car is subdomains and put on supports. Rear wheels with cars are removed. Dismantle will also have;

- next, adjustment and locking on the equalizer are unscrewed, and the cable terminals are removed from it;

- then it is necessary to remove the crossies from the levers in the brake mechanism. To retrieve, it remains only to distribute fastening of cables to the back of the beam and extract them.

Syringe and engine oil can be used to lubricate the scurrical cable. It is necessary to download it until it fails through the entire length of the braid, then you can try to develop a cable, alternately moving it out of the terminal.