Zis 5 drawings of the cab and frame. Four generations of trucks

From the heroes of the old days

Sometimes there are no names left.

Those who have accepted mortal combat

Became just earth and grass ...

According to the already established tradition, new projects were prepared for the Victory Day. In past years, these were three Su-37 for group aerobatics.

This year, a new ZIS project was launched for Victory Day. With flights, it was still not clear whether it was allowed or not.

So, the car is a veteran ZiS 5V. The grandfather of our chief designer of this project during the Second World War was driving to Victory in such a car. This is the memory of him and other veterans of the Second World War.

In terms of events, it was that this model will take part in the Victory Parade on May 9 in the Column of the College where we are now based. We managed to prepare everything less than a day before the events. In less than a day, it was decided to make a frame and an awning in the body.

It was decided to use a ready-made chassis based on Baja at a scale of 1: 5 for the scale of the project.

The car is new, just run-in. It was the rear-wheel drive version that was chosen to "stretch" it for a future project.

The front part with the electronics is disconnected from the frame. The frame is increased in length by 50 cm. Wheels with a diameter of 25 cm.

The main problem was in assembling the frame and making the wheels themselves or using ready-made ones.

In winter, various options were considered, but they presented some difficulty, although, according to the plan, they should look more copy-like. But this was abandoned in favor of finished products. The solution was found in the use with the modification of finished wheels from carts. So, 7 wheels are prepared. incl. one spare. A drawing was taken on the emery on the sides of the tires. The hubs were dismantled and in their place were made of wood for stock hexes for more convenient installation. The rear wheels are double, connected by screws. The wheels are chambered, everything is left as is.

The frame is reinforced at the bottom with aluminum corners. At the top with an aluminum rail. The body and the cabin will be attached to it.

From the electronics side, the steering servo radio boxes have been moved forward as they were in the stock version. The brake servo was left in the stock location on the new mount due to the reason of not changing the settings for dismantling and collecting the stock version of the Baja.

Drawings were made on a scale of 1: 1. On them and is the assembly of the car.

Variants of making a body, a cab from plywood were considered, but due to a more exact match, it was decided to make it from slats, everything is as in the original.

To maintain the proportions, a ZIS 5V model was assembled at a scale of 1:35.

It was on it that the number of boards (rails) in each node was calculated. Thus, the body and the cab contain the same number of slats and planks as in this scale model. The dimensions are also respected.  Body boards, cabins are glued together. Tied into a shield with clamps and wedges. The body is finished with small copy parts - hinges, awnings.

Body boards, cabins are glued together. Tied into a shield with clamps and wedges. The body is finished with small copy parts - hinges, awnings.

Cabin.

As in the original, it is made of planks (slats). The hood and roof will be made of tin. Ventilation ribs are made on the sides of the hood.

The steering wheel is made, the seat is modeled as in the scale model.

The doors are also recruited from slats. Opening doors.

The local art school, (children of the art modeling circle), were engaged in the manufacture of a driver and a passenger. The driver was sculpted from the photo of the grandfather of the Chief Designer of this project.

To reduce the volume of the exhaust, a muffler is assembled from corrugations and squeegees of water pipes. A metal mesh was placed in the barrel.

The model is quite heavy. The stock 26cc engine is rather weak for her. In general, the task was to drive along a flat straight line, on asphalt. Which was done. The sound, the smoke, everything was as intended.

The task was not set to maximum detail and similarity to the prototype, but we tried to make it similar.

Perhaps we will later convert it to an electric version. The stock 26cc engine is weak for her.

Model making.

Frame break-in

Participation in the parade. In general, everything turned out as planned. At the end of the parade, the model was exhibited for a photo session for everyone, of whom there were plenty, even queued up.

It was nice to listen to the old people who said that they had a chance to ride on such trucks after the war, as well as those whose fathers and grandfathers went to the front and returned in such vehicles.

Of course, there will be replicas - cars assembled on the basis of modern units, but outwardly similar to these three-ton. But there are still places where you can see a real ZiS, even with a new cab and body - the tree cannot survive for seventy years. But a real ZiS will have a dear heart - a motor. Where do these units come from now? This is what we will devote today's material to, a story about how the restoration of the motor takes place. To do this, we watched for several months how the engine is being restored in one of the best restoration workshops in St. Petersburg, RetroTruck.

It all starts with theory

Before proceeding with the story about the process, let's say a few words about the ZiSa motor. It is called that - ZiS-5, just like the car. Its production began in 1932, and its very close relative can be considered the American Hercules unit, and the ZiS-5 engine was used on almost all pre-war trucks and buses - there was simply no other engine.

1 / 4

2 / 4

3 / 4

4 / 4

ZiS-5 "1933–41

Its capacity is 73 liters. with., volume - 5.55 liters. This six-cylinder engine is low-speed, and with a torque of 279 Nm at 1,200 rpm, it has a locomotive thrust. The motor has an in-line arrangement with a bottom valve arrangement. Since during the restoration we will still have time to pay attention to the peculiarities of its design, we will finish the theoretical part on this and proceed to ... the search for our future motor.

Such different people

Obviously, military equipment should be sought where there was a lot of it during the war. But not every motor found can be restored: a lot depends on where this motor was found. The main enemy of any iron is corrosion, rust. It is formed during the oxidation of the metal. There were times when from the bottom of Ladoga they raised seemingly magnificent specimens of equipment (after all, we remember, for example, about the Road of Life, don't we?). But working with them did not work: the iron was almost completely destroyed by water. The most "unbearable" storage conditions are warm and humid air. Another thing is a technique that has lain somewhere in the northern region, in a swamp, where clay blocks the access of oxygen. Or at least just in the ground, but better - in a cold climate. If you are very lucky, the motor can simply be cleaned and it will be almost in working order. But this, unfortunately, is from the category of miracles, usually old motors (more precisely, blocks) are in a very poor state, and with some there is no point in messing around at all. Therefore, the first thing a restorer has to deal with is the search for a future engine and its attachments. Where was that motor found in our story? Different people walk in our forests, steppes and swamps. They are not interested in mushrooms and berries, but in scrap metal, which in some regions has remained since the Great Patriotic War. Until now, they find a lot of all kinds of iron, sometimes interesting, sometimes not. Let's say, found such a "search engine" metal, what will it do next? In the worst case, he will hand over to the metal collection point. For a penny, but quickly. In this case, no matter how valuable his find turns out to be, she has only one way - to be melted down. And restorers can only guess what kind of "wealth" they have lost due to the activities of people of this type. There is also another extreme. A person who finds something interesting is trying to sell his find as expensive as possible. He puts up for sale, arranges auctions, wants to squeeze out the maximum profit. Sometimes it works, sometimes it doesn't. It is bad that the prices for his finds can be so inhumane that something valuable again passes by the restorers. The owners of RetroTruck are lucky to know a good person named Valera. He has a job, and searching for old hardware is more of a hobby and, of course, additional income. What does Valera have that many others do not? Most likely conscience. He understands what can be scrapped and what not. But the price for interesting finds never breaks, he sells at the price of scrap, the main thing is to get to someone who is really interested in it. One of the finds seemed interesting to him, and he sent a photograph to his friends from the restoration workshop. On it is the ZiS-5 engine block. "Must go!" - decided in the workshop, got into the van and drove to Medvezhyegorsk. In the photo received by mail, only the block was shown. On the spot, everything turned out to be more interesting - a huge pile of scrap metal from all eras, except, perhaps, the Neolithic - everything was made of stone.

At the machining center for engine parts

The disassembled engine is sent to a specialized workshop, where the craftsmen will be engaged in the restoration of the block and crankshaft. Before that, specialists from the restoration workshop and PKF Motor Technologies LLC carefully examine the block and determine the future scope of work. There are no cracks on the block, which is good. But there is a lot of work to be done. First, the block must be sealed. The technology of this operation is no different from that used in the repair of modern engines. But with valve seats it will be a little more difficult: the ZiSa unit, in principle, has no seats, there are only seats. Time did not spare them, they have defects. We'll have to repair them.

The repair method is quite obvious: the installation of bushings, followed by the manufacture of a seat for the valve disc. We will see how this is done. In the meantime, let's note this fact to ourselves and move on to the crankshaft. The crankshaft was not in the worst condition. Here it was not necessary to weld the main journals, but, of course, one cannot do without grooving and grinding. And this operation must be carried out as quickly as possible: how much babbitt will have to be poured onto each crankshaft support depends on its results.

1 / 3

2 / 3

3 / 3

What does it mean to fill? There are also inserts! But no. The sliding bearings in the ZiS-5 motor are filled with babbit (antifriction alloy), there are no main and connecting rod bearings. Why was it done using this technology? Because it is the most maintainable solution. Imagine an era when a trip over a hundred kilometers is already "long-range", there are no auto parts stores, and the engine needs to be repaired. Where can I get the earbuds? What is the repair size? There were no cell phones either, you get up on virgin soil - you have to get out yourself. This is where babbitt came in handy. Many took with them ready-made mandrels, into which they could pour molten babbitt and get a new "insert". Of course, the tolerances in those days were simply huge, the machining center machines for such repairs turn out to be even too accurate, but still, you have to control the parameters during boring every second. Now modern high-precision machine tools are used for this, and then such equipment was only in large factories, in MTS (machine and tractor stations) and similar enterprises. The main and connecting rod bearings were bored by hand. For the main inserts, special devices were made, which were attached to the block, then the handle was twisted, and the cutter, mounted on the screw mechanism, bored the support. The connecting rods were bored with a mandrel on a conventional lathe. In addition to grooving the crankshaft supports, it is also necessary to prepare the camshaft bushings and cylinder liners. Here everything happens according to modern technologies, about which a lot has already been said. The camshaft bushings, like the crankshaft bearings, are bored in one "pass". The liners, like the pistons installed on this engine, are from the reserves of Yakov Fedorovich - the original, factory ones. Even the fastening of the pin in the connecting rod remained "correct" - the bolt on the connecting rod tightened the finger tightly in the head and freely entered the piston. On modern engines, the pin is rigidly attached to the piston, but has a gap in the connecting rod bushing.

1 / 4

2 / 4

3 / 4

4 / 4

So, the crankshaft supports are ready. But what are the copper plates under the crankshaft bearing caps? And this is again another way to simplify the repair of the motor. This is not an initiative of modern repairmen, as it might seem at first glance: thin copper plates were installed at the factory both during the manufacture of a new motor and during its overhaul. Babbitt is a soft material. If now multilayer liners serve tens, or even hundreds of thousands of kilometers, then a flooded babbitt wears out thousands over 20 kilometers. It is then that they remember about the copper gaskets. The repair was carried out as follows: they removed the oil pan, support covers, pulled out one plate and put everything back together. That's it, the motor is in working order again! Every driver should have been able to do such an operation (come on, tell me how you know how to fill "non-freeze" in your Focus!). The number of plates varied from three to five - they were placed in different ways. This means that the engine could be repaired three to five times in a few hours. Not completely, but somehow.

1 / 4

2 / 4

3 / 4

4 / 4

The work on the block and crankshaft is completed. The engine is now returning to RetroTruck.

About spare parts and methods

How is our insert on the valve seat doing there? As you can see, it has changed its shape - now there is a saddle. How was it made? There is such a tool - countersink. Its full definition sounds like this: a multi-edge cutting tool for machining holes in parts in order to obtain conical or cylindrical recesses, support planes around holes or chamfering center holes. This is how the workshop specialists worked. But their countersinks have a very interesting feature: they are made specifically for the repair of engines of Soviet trucks, namely, GAZ-AA and ZiS-5. Yes, an old motor is an old instrument! At the end of the work, a practically new valve seat is obtained. Can the motor be assembled? But no.1 / 5

2 / 5

3 / 5

4 / 5

5 / 5

The block, pistons, valves, liners, crankshaft - these are all, of course, wonderful details, but this is still far from the whole engine. If you have all the components, the restoration will take one and a half to two months. But it does not happen that fate sends a brand new generator, starter, water pump, oil pump, distributor, filters, or at least a set of springs for valves or piston rings to a found motor. Collecting everything you need, completing the engine is just a hell of a job, and it sometimes lasts for years. Until everything you need is collected, there is no point in even starting to tinker with the block. Where to get spare parts? The owners of the restoration workshop were lucky to know an amazing person - Yakov Fedorovich Lisin. This man became the driver of the ZiSa-5 back in the war, in 1943. And he was him until the last days of his life - until 2009 ... It's incredible, but the mileage of his truck, on which he worked all his life, during this time amounted to more than four million kilometers! After his death, ZiS ended up in a restoration workshop, and a huge amount of spare parts for the "three-ton" vehicle moved with him to a new place of residence. Moreover, both already used and completely new (even half a century) parts. Of course, among this "wealth" there is absolutely nothing, but a lot is used from the reserves of Yakov Fedorovich. And yet a lot has to be restored - it is impossible to use a "remake" in a high-quality restored car.

1 / 3

2 / 3

3 / 3

It is easy to restore the oil filter: cut the felt boot and you're done, because this filter was made of felt. But with most of the other units, there is much more work. Take a look at the pictures of the current water pump and how it looked before it was restored. I don’t know about you, but I was very impressed. Once upon a time I drove on a penny in 1978 and was extremely happy when I changed the starter brushes myself for the first time. But what is a neglected case and how to treat it, I understood only when I saw what was happening with the starter or generator in the hands of the masters.

1 / 9

2 / 9

3 / 9

4 / 9

5 / 9

6 / 9

7 / 9

8 / 9

9 / 9

Assembling a new old motor

After all the attachments are assembled, the fun begins - the assembly of the engine. There are no these of your phase change systems and intercoolers with turbines, so the assembly is done pretty quickly. While the team of the restoration workshop lovingly and lovingly tightens the nuts, we can finally appreciate the design features of this unit. Question one: why do we need the wire on the bolts of the crankshaft covers? The fact is that it was the easiest way to "lock" the bolts, to prevent their possible loosening. The growers were already there, but not in responsible places, and the wire was everywhere in bulk. I note that such a breathtaking technology was used even after the end of production of the ZiS-5. For example, in the engines of the Gorky Automobile Plant. Question two: what is the cover on the oil pan? This cover is one of the hallmarks of early motors. Removing it, it was possible to get to the oil pump, although there is also a separate drain plug for oil in this cover. Later, the crankcase lost this part. If we started talking about what changed in the ZiS engines during the time of their production, let's talk about this in a little more detail. The modernization of the engine took place gradually, so it is impossible to unequivocally name the year when the engines changed. But you can roughly say: the early units differ from those that were produced after 1938, and changes began to be made back in 1936. Firstly, the units produced before 1938 do not have a water jacket cover. After 1943, the block head changed: grooves for spark plugs appeared. Thus, the volume of the combustion chamber was reduced, increasing the compression. Based on these and some other signs, it can be established that our motor is one of the earliest, produced before 1936. But back to the design features of the engine.1 / 3

2 / 3

Earlier we talked about, a brief historical background was given and detailed photographs of this truck were presented. Today I want to tell you about the construction of his model on a scale of 1:72 from the "Elf" company.

Overview of the ZiS-5 model

If we first consider the kit itself, then we can say with confidence that today, with a number of shortcomings, this is the best model of the ZiS-5 truck on a scale of 1:72. True, it is very difficult to acquire it now. First, a quick overview of the source material. The model represents the ZiS-5V car, it consists of seven small sprues, body platform parts, two frame parts, cockpit fenders and footrests, glazing, rubber tires for wheels, instructions. There is no decal in the set.

Everything is cast very high quality, however, there are two small sinks on the body platform. The wheels are made of very high quality, I hope those who know the products of the Elf company will understand what is at stake, the headlights consist of several parts, including reflectors.

Assembling the ZiS-5 model

Let's move on to the assembly itself. At the first inspection, the minimum scope of work becomes immediately clear. What I noticed right away was the radiator grill. In the set, it is very weak, it needs to be changed. In the photo above, this is clearly visible. I really didn’t like the wings, but I’m afraid it’s a technology cost. Although, at a scale of 1:72, I saw thinner and more delicate elements, made much more accurately. Well, the initial scope of work has been determined, the rest will become clear along the way. Let's start with the radiator. From the plastic part, I left only the edging, cut out the rest and chose from the inside with an engraver to install the metal mesh. On the reverse side, I made an insert of sheet polystyrene and laid it with a two-component putty for Tamiya models. The result is such a detail.

After I assembled the engine hood. Since the lower part of the radiator grille is smaller than it should be, it had to be increased according to the drawing and photo.

In preparation for work, I read peer reviews and model building descriptions. It noted that the rear wall of the cab is narrower than necessary. When checking against the drawing and recalculating the dimensions to a scale of 1:72, it became clear that this is indeed the case, therefore, the part needs to be done again. I made it from sheet plastic. Due to the change in the width of the rear wall, the roof had to be re-made, also from a piece of polystyrene. When assembling the frame, it turned out that it was somewhat short, respectively, the axles of the wheels did not coincide either with the drawing or with the overall dimensions. I had to build up the frame, white inserts are visible in the photo. I also needed to putty the sinks from the sides.

During dry assembly of the bridges, it was found that the frame was not parallel to the ground. I had to make substrates on the front springs. In the photo, they are visible from white plastic.

The next stage, as expected, turned out to be quite difficult - making the wings. When looking at the photos, it turned out that there are several options for the execution of this unit. I had to stop at one of them and think about how to translate it into metal. First, I cut off the plastic fenders from the part of the bottom of the cab.

Then I made wing patterns from paper, and then, from copper foil, I made plates of the desired shape, and bent them in the right way. Then, using the same principle, I made the side, inner parts of the wings.

It didn't work on the first try, but in the end, we have the following result.

While all the units are disassembled, I made the headlight brackets from foil and copper wire.

I made the door handles in the same way.

Made of copper foil, made the footrest brackets

Now, after the final assembly of the cab, body and a number of adjustments, this is an intermediate assembly of the entire model.

After that, I made handles for opening the sides of the body and assembled the headlight brackets. Then, again, an intermediate assembly with a fitting.

Then I made and painted the inside of the cab: the steering wheel, the gearshift lever, the pedals, and added some other little things. Now you can start painting work. All glasses were limited, along the contour, with thin strips of Tamiya tape and closed with a stop color Mr. Masking Sol from Hansa.

For painting used paint AKAN, color 4BO. This ZiS-5V was made for the exhibition on May 9, painting was done at night, before the deadline. Due to the lack of time, there was no talk of toning and washes. In the morning, almost all the remaining elements were installed: headlights, a muffler with an exhaust pipe, wheels and all the components were glued. In this form, the model was put up for the competition, where it won first place, sharing it with a colleague in the nomination. According to legend, the car has just rolled off the assembly line. Further, of course, tinting and washes will be applied, the glass will be cleaned, there are a number of shortcomings. While the model is lying, I can’t find the state. number on the tailgate and cabin doors. In the meantime, a small video and a gallery of photos of the newly painted work.

For painting used paint AKAN, color 4BO. This ZiS-5V was made for the exhibition on May 9, painting was done at night, before the deadline. Due to the lack of time, there was no talk of toning and washes. In the morning, almost all the remaining elements were installed: headlights, a muffler with an exhaust pipe, wheels and all the components were glued. In this form, the model was put up for the competition, where it won first place, sharing it with a colleague in the nomination. According to legend, the car has just rolled off the assembly line. Further, of course, tinting and washes will be applied, the glass will be cleaned, there are a number of shortcomings. While the model is lying, I can’t find the state. number on the tailgate and cabin doors. In the meantime, a small video and a gallery of photos of the newly painted work.

Video and gallery of the ZiS-5 model

The legend of the Soviet automobile industry, the ZIS-5 truck dates back to 1933, when its predecessor AMO-3 was modernized. Then the power plant was updated, increasing the engine power and, as a result, the carrying capacity of the machine.

The legend of the Soviet automobile industry, the ZIS-5 truck dates back to 1933, when its predecessor AMO-3 was modernized. Then the power plant was updated, increasing the engine power and, as a result, the carrying capacity of the machine.

The ZIS-5 had a very durable engine. Another very valuable feature of the "three-thin" was that almost all of its parts had such proportions and dimensions that they could not be damaged or broken even with the most rough and inept handling. The simplicity of the car meant a lot for the convenience of maintenance and repair. It consisted of only four and a half thousand parts, and its assemblies could be disassembled and repaired with minimal use of special equipment and tools. The three-tonka turned out to be an indispensable machine for working in the conditions of that time. The engine started easily in cold weather, and ran on any grade of gasoline. The car stood out for its good cross-country ability and won the sympathy of drivers. It withstood the tests of the war with flying colors, was modernized more than once and was discontinued (its last version, the Ural-355M), only in 1963. Thus, if you keep score from AMO-2, then this truck, which has become almost legendary, has been in production for 33 years.

Many interesting pages of the biography of the Soviet automotive industry are associated with the ZIS-5 car. It was the first domestic car to be bought abroad in 1936. When the Nazis approached the capital in 1941, the Moscow plant had to be evacuated to several cities, and a simplified version of the "three-ton" (ZIS-5V, that is, wartime) was produced at the Ural automobile plant. But the Moscow plant also resumed production of the same trucks in 1942. During the war years, the ZIS-5 meekly carried guns and wounded, ammunition and food. He carried a difficult service on the "Road of Life" that ran from Leningrad besieged by the Nazis on the ice of Lake Ladoga, went through the frosts and fire of Stalingrad, participated in the liberation from the fascist yoke of European countries.

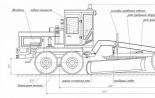

XI dimension characterizes the inclination of the frame relative to the ground in the area between the axles with a load of about 50 mm, without a load of about 140 mm. In the drawing, the frame is shown horizontal, and the ground is inclined, for the convenience of taking measurements of the body, the lines of which are parallel to the frame or are located at right angles to it.

Numerous models and their modifications were produced on the basis of the "three-ton". Among them, it is necessary to highlight all-terrain vehicles - three-axle, - half-track and with a drive not only to the rear, but also to the front wheels. The first Katyushas were mounted on a three-axle ZIS-6 chassis.

In parallel with the military branch, the civil branch also developed. So, in 1933, an elongated ZIS-11 chassis appeared (it was used for fire trucks), and three years later the production of gas generating machines began. The fuel for them was the gas obtained from wood chunks in gas generators. Based on the experience gained with these models, it was possible to create a ZIS-30 truck, for which liquefied methane or luminous gas served as fuel. The calorific value of this fuel is significantly higher than that of generator gas.

Over time, the "three-ton" engine became more and more powerful (up to 85 hp), a hydraulic brake drive appeared, in 1956 the car acquired a rounded steering mechanism. Finally, from 1958 to 1963, the Ural-355M was produced. It was distinguished by an all-metal cabin of the GAZ-51 type, new fenders, a radiator lining and a hood.

At the Moscow plant ZIS-5V held out until 1946. It was replaced by another truck - the ZIS-150. It was a significant step forward. It had a five-speed gearbox, air brakes and many other design differences. On the basis of its units, the ZIS-151 with three drive axles, a truck tractor, a dump truck, as well as cars running on liquefied and compressed gas were produced.

ZIS-150 - the successor to the ZIS-5 on a pedestal in Ivanteevka near Moscow

A large family of ZIS trucks gave rise to two more related lines. In 1951, the production of "Zisov" truck tractors and dump trucks began in Kutaisi. Almost simultaneously, the Mytishchi machine-building plant began to build on the basis of the chassis obtained from the ZIS, dump trucks and road trains with truck tractors. In the mid-fifties, the ZIS-150 had new "relatives": trucks were built on its model in China and Romania.

In 1957, the ZIS-150 underwent a radical modernization, after which the car received the index 164, and later - 164A and 164AP. Outwardly, these cars differed slightly from the ZIS-150, but they had engines of greater power and improved units. Since in 1956 the plant was named after I.A. Likhachev, who was its director for a long time, then all models received the designation "ZIL". The ZIS-151 was replaced by the ZIL-157, equipped with single wheels and a centralized tire pressure control system.

By 1965, the Likhachev Automobile Plant created a completely new basic model of a truck. She gave rise to the fourth generation of trucks of this enterprise. The first, the ancestor of which was AMO-F15, existed for seven years. The second, which began with the AMO-2 and developed into the ZIS-5, as we already know, spanned three decades. The post-war generation of the ZIS-150, the third in a row, was almost twenty years old. It retained the most important engine unit - the continuity from the ZIS-5 and even from the "Avtokar"; Inch measurements of many parts have been preserved, for example, starting with AMO-2 and up to ZIL-164A, but the size of the piston stroke has changed - 114.3 mm, that is, exactly 41/2 inches. Despite numerous improvements, this engine was outdated by 1965. The transition to a new one inevitably required the reconstruction of other units, the entire car. And in 1965, a ZIL-130 with an overhead valve eight-cylinder engine entered the conveyor. Along with this model, its modifications were produced - 130G with an extended base, 130V1 truck tractor, MMZ-555G dump truck, ZIL-131 car with stirrups.

At the beginning of the 1960s, the Ural Automobile Plant prepared a three-axle off-road model, the Ural-375, to replace the "three-ton". On its basis, a truck tractor and a road-type truck are also produced. The engines installed on them are manufactured at ZIL and are of the same type as the engines of the ZIL-130 and ZIL-131 models.

The ZIS-6 is distinguished by the presence of a third axis and a slightly enlarged radiator. The half-track ZIS-22, ZIS-42 have caterpillars instead of the rear wheels, the ZIS-10 tractor has a support linkage instead of a platform. The cars of the pre-war production (before the evacuation of the plant to Ulyanovsk and the Urals) had no cab visor, buffer and front brakes, the mudguard of the footrest was shortened.

The cabin of the ZIS-5V (and all its modifications of the war and post-war times) is sheathed with wooden slats, the so-called "clapboard"; stamped wings were replaced by angular welded ones, and the platform's steel hinges were replaced by wooden posts; a significant part of the cars were produced with one (left) headlight, which was equipped with a blackout disc.

The external details of the main model ZIS-5 do not require special explanations - they are visible in the drawing. You just need to pay the modeler's attention to the new roof lining (which differed in color and texture from the color of the entire cab), the absence of horizontal stamping in the area between the hood and the door, the corrugation of the footrest, the steering wheel hub protruding upward with two shifters on it. Distinctive tire tread pattern with lugs extending to the sidewalls. Simple shapes of the engine and other mechanisms (this is for those modelers who want to make the hood open, and also show the chassis details from below) schematically in the drawing. Inside the cab, don't forget the wooden door sills and ceiling slats. The rear light is single, located on the left.

ZIS-5 cars were most often painted in a light protective green color, including the radiator lining and fenders. Wheels, frame and all chassis mechanisms, as well as headlights (except for chrome rims) were black. Cars intended for export were painted beige, and the radiator lining, headlight housings, bumper and wheel nuts were chrome plated.

Y. DOLMATOVSKY candidate of technical sciences, L. SHUGUROV, journalist

In the Arkhangelsk region, on one of the islands of the White Sea, the ZIS-5 miraculously survived, abandoned there back in the 60s due to the complete absence of roads. This is how we saw him.

The power unit turned out to be completely native, and the cutout in the engine shield was made by the driver who once drove this ZIS in winter. We need this cutout so that the warm air from the manifold goes directly into the cab.

The cab on this ZIS at the end of the 50s was replaced with a new one from the UralZIS-355 car. This is evidenced by the "late" steering column mounting bracket, a torpedo without an air intake hatch and a characteristic flange.

The rear axle with mechanical brakes, propeller shaft, brake rods are in very good condition. The body, of course, was not preserved, but later we found its exact drawings.

Before the war, the spare wheel bracket was installed at the rear under the frame, which was extremely inconvenient for operation. Since 1943, other brackets began to be installed on ZIS-5V cars, they were attached under the body on the right side.

The engine clearly shows the marking of the month and year of manufacture - March 1941, which is confirmed by a similar casting on the manifold. The fenders are also in good condition, even the bonnet locks have survived.

Even the factory engine protection has been preserved on the car. Usually, however, such protections were not preserved for two reasons: firstly, during operation, they severely rusted and rotted, and secondly, if the engine was removed from the car, then these shields were usually no longer put in place.

Before pulling out the ZIS, they had to dig it out of the snow and clean the road.

Special thanks to the virtuoso tractor driver of the Krasnoye Znamya fishing collective farm Sergei Ivanovich. He very carefully pulled the ZIS from the distant island to the mainland.

For the motor shield corresponding to the year of production of the car, I had to go to the area of the village of Luga, Leningrad Region. During the retreat in 1941 from Pskov to Leningrad, a lot of equipment was thrown in the swamps, and you can still find some Western ones. parts. In the photo, Alexander Olegovich Pavlov, a connoisseur of the ZIS-5 car. Thanks to his participation, our ZISs are among the best in the world in terms of the degree of restoration.

Since our ZIS did not have a hood and many more parts, we needed to find them somewhere. Invaluable help in this was provided by Vadim Igorevich Matveenko - the main "ideologist" of our project, candidate of historical sciences, author of the book "Forgotten and Famous".

Since the pre-war app. parts can only be found deep in the forest, then they had to be pulled out in this way.

The engine had to be seriously repaired and completed with missing spare parts. parts.

The cockpit was restored according to the factory drawings and samples found earlier.

The body is made of wood, made according to drawings and found metal elements. Painted in the same color as the cab.

Locks, body hinges and nuts are of the early type (until 1938). Chauffeurs did not like such locks very much - because of them, the sides were opened on the move, and were subsequently replaced with “American-type” locks, which are still installed on Russian trucks.

A 3-brush generator of the GBR-4600 brand, an MKZ-6 carburetor of the 1938 model, an MAAZ-5 air filter, a gas pump of an interesting design - an original "trim" of the engine.

The oil filter has a set of felt rings (you can cut it out of an old felt boot, rinse it and move on). The "Ross-Gear" steering system transferred the force from the steering column to the steering mechanism. On the engine block, you can see a triangle with the inscription ZIS, and under it - the year of manufacture.

The tire inflation pump was installed on the gearbox and powered by its gears.

The universal joint shaft has no elastic joints. Both hinges are metal of the "Spicer No. 500" type. The rear wheels have mechanical drum brakes with two pairs of pads, one of which is operated by the handbrake lever and the other by the brake pedal.

The front brakes are also mechanically actuated. Front brakes are very rare on ZIS, they practically did not work and required constant adjustments. Many drivers simply took them off and threw them away.

Difficulties with the restoration of the spare wheel bracket did not arise, and the hitch also had to be taken out of the forest.

The electrical equipment on our car is 6-volt - an original instrument panel with a speedometer, a pressure gauge, an ammeter and a central light switch that is quite difficult to repair. The starter button is visible below.

The gearbox of the ZIS car was installed original, it is a modernization of the gearbox of the company "Brown and Line" with increased dimensions of the gears. A gasoline tank with a volume of 60 liters was under the driver's seat - it is difficult for a modern person to understand the logic of designers, because to refuel it is necessary to open the door and remove the seat! Obviously, this was necessary so that the driver did exercises daily and did not smoke while driving.

The machine is ready for sea trials. A set of native rubber brand Ya-1 in size 34x7 (corresponds to the modern marking 200x508) produced by the Leningrad plant "Red Triangle" in 1938 is installed only for the duration of the exposition. For sea trials, a more modern rubber of a similar size is used.

Kasymov Alim Dzhumanazarovich - chief engineer, technologist, minder, aggregator, tinsmith, painter. There are no parts in the car that have not been in the hands of this ingenious person.