Technical characteristics of mksm. Technical characteristics MKSM Tractor MKSM 800 technical characteristics

In the economy of any enterprise, maneuverable, easy-to-operate and maintain equipment capable of performing many functions is especially popular. The miniature loader MKSM 800 possesses all of the above characteristics; the technical characteristics of this machine allow it to perform many tasks.

Areas of use of the mini loader

The MKSM 800 loader is manufactured at the Kurgan Machine-Building Plant. This multi-purpose machine is easy to operate, has a smooth ride, due to its small size, it can work in confined spaces and is easily transported without the involvement of expensive special equipment. It has high speed and good performance.

The features of the loader allow it to be successfully used in public utilities for moving goods in warehouses, during construction work. It turns out to be an indispensable assistant when cleaning garbage and snow, digging trenches, drilling wells, landscaping streets and landscaping areas.

Due to its dimensions, the MKSM-800 mini-loader can perform work where the use of other special equipment is impossible, including indoors.

What can be additionally equipped with a loader

Numerous attachments that are quick and easy to install help expand the machine's range of uses.

Mini-loader MKSM 800, in addition to the frontal bucket, can be equipped with:

- open pit bucket for loading lump materials;

- bulldozer blade for land management and clearing the area from snow;

- a jackhammer for crushing hard rocks and materials;

- bucket or trench excavator used for excavation and digging trenches;

- forks (cargo or clamping) for working in a warehouse and loading long lengths;

- drilling equipment for planting trees, installing supports and foundations;

- snow blower;

- brushing equipment for cleaning the territory;

- concrete mixer for the preparation of concrete solutions;

- a ripper used in landscaping and sowing;

- reagent spreader;

- cargo pin for moving roll materials;

- rubber-metal tracks, allowing to improve the cross-country ability of the mini-loader.

Mini loader parameters

The loader can turn almost in one place and smoothly change the speed, which is ensured by the presence of a volumetric hydraulic drive and stepless gear shifting. Maintenance of the MKSM-800 is not particularly difficult due to easy access to all its nodes. Defective items or consumables can be replaced within a short time.

Dimensions of mini-loader MKSM 800

Technical characteristics of MKSM-800:

MKSM 800 engine parameters

Loaders are equipped with Cummins engines (manufactured by an American plant) or German HATZ. The latter is included as standard. They run on diesel fuel, the power varies from 32 to 38 kW (44-52.9 horsepower). Installation of Japanese power units "Kubota" is also possible.

The distinctive features of mini-loaders are:

- a long period between scheduled maintenance;

- automatic shutdown in case of pressure drop or belt drive breakage;

- the use of an air cooling method, which eliminates the need for a radiator and coolant (for models with a HATZ engine);

- engine resource of 18 thousand hours.

Fuel consumption rates

MKSM 800 is economical. The machine is equipped with a tank with a volume of 55 liters. On average, a forklift truck requires about 6 liters of diesel fuel per hour.

Cabin structure

In the manufacture of the MKSM 800 mini-loader cabin, an all-metal profile, glued-in glass and swing vents were used. The design is reliable, able to protect the driver from falling loads, as well as overturning.

The operator's workplace provides for the location of all control levers and display systems, it is arranged in accordance with all safety and ergonomic requirements. A climate system has been installed that provides comfort in winter and hot days, hooks for clothes, boxes for storing things and parts.

The cab door is its front side. The MKSM 800 loader cab is lifted for access to the machine units and is fixed by means of the provided devices.

The wide glass provides excellent visibility. A screen wiper is installed to clean it. In emergency situations, the rear window is used to go outside. The windows are made of heavy-duty glass. If necessary, the cab windows can be replaced with grilles.

Modifications of MKSM 800

The plant produces the basic model of the loader, as well as its modifications 800K, 800N, 800A and 800A-1, which differ in the engine model and equipment.

What are the characteristics of the MKSM 800 mini-loader models:

- MKSM-800A- installed a Cummins A2300 engine with 4 cylinders with a capacity of 48 hp;

- MKSM-800K has a Cummins A2300 engine with a capacity of 44 hp;

- MKSM-800N equipped with a Hatz 3M41 three-cylinder power unit with a capacity of 52.9 hp;

- MKSM-800A-1 equipped with a four-cylinder Kubota V2403 engine, producing 51 hp.

Frontal mini-loader MKSM-800 is a special unit that performs multiple functions in the municipal construction sector. The main types of work include: planning the area for construction, loading and unloading a variety of bulk materials, drilling, shaping trenches and depressions in the ground, removing snow in winter, as well as performing simple work in warehouses.

The multipurpose loader MKSM-800 is manufactured by the Chetra group of companies. It gained its popularity on the market due to its relatively small size (compared to competitors) and the implementation of many simple, quick and necessary tasks in construction and municipal services, where often large-sized equipment cannot be used for its intended purpose.

Review of loader MKSM-800

Description

This type of equipment, as we wrote earlier, refers to multi-purpose special-purpose equipment due to the large number of interchangeable equipment that is used to perform various kinds of tasks.

It is useful to know that the replacement of attachments on a mini-loader can be performed even by one operator, because the technological process of replacement is quite simple and does not require special technical knowledge from the operating personnel. Moreover, the replacement of equipment is carried out in a short period of time, which is highly appreciated in the production of work!

MKSM-800 for organizations and entrepreneurs is an excellent option for work in "tight" overall conditions. There is always work for this type of equipment, which means that the loader will pay off very quickly, which is very, very profitable. I would also like to note that the cost of the work performed using the small-sized MKSM is significantly lower in comparison with other equipment.

Main features of the loader

The considered version of the equipment is deployed literally on the spot and by means of the volumetric hydraulic drive with infinitely variable speed switching included by the Chetra engineers in the list of equipment, it smoothly picks up and decreases the speed. The control is carried out by means of two joysticks, which is quite simple!

Compared with competitors' analogues (CASE 410 and Lui Gong 365A), the considered option has pronounced distinctive features and characteristics. Let's highlight some of them:

- A quality engine from John Deere or Hatz, which fascinates us a lot.

- Higher rates of cross-country ability and handling even of a standard chassis.

- Developed and installed volumetric hydraulic drive (we wrote about it just above).

- Convenient location, and hence the use of controls.

- Maintenance, daily inspection and repairs are made much easier due to design features.

Varieties

Today on the market there are not only standard MKSM-800 models, but also some of their modifications with various applications of the main components and assemblies. Let's describe each of them in more detail.

Model MKSM-800A - has a welded frame and a special clutch is installed for work at negative ambient temperatures.

Model MKSM-800K - is completed only with a diesel power unit from the American company John Deere, in rare cases from Cummins.

Model MKSM-800N - is completed only with a diesel unit of the German company Hatz.

Model MKSM-800A-1 - is the latest fresh modification with pneumatic wheels and tubeless tires, as well as improved chassis suspension.

Main technical characteristics of MKSM-800

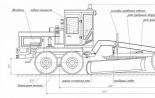

The mini-loader, depending on the modification, is equipped with a power diesel unit, which has a specific diesel fuel consumption of 161.8 g / h.p. per hour or 220 g / kWh, which is quite economical. The upper limit of the maximum speed is 10 km / h. The fuel tank, fixed to the chassis, holds 55 liters of diesel fuel. The main dimensions are shown in the figure below.

Other characteristics of the model in question are shown in the table below.

| Characteristic | Index |

|---|---|

| Total weight, t | 2,8 |

| Maximum lifting capacity, t | 0,8 |

| Maximum speed, km / h | 10 |

| engine's type | Diesel |

| Power unit power, hp / kW | 46,2/34 |

| Fuel consumption per hour, g / hp h or g / kW * h | 161,8/220 |

| Maximum tractive effort, kN | 24 |

| Transmission | Hydromechanical |

| Chassis type | Wheeled |

| Tank volume, l | 55 |

| Track width, m | 1,41 |

| Unit length, m | 2,48 |

| Unit height, m | 2,065 |

| Control type | Mechanical or electrical |

How much does the MKSM-800 loader and its analogues cost?

Price loader MKSM-800 varies from 1 to 1.3 million rubles, depending on the choice of attachment equipment. The closest analogue - CASE-420 will cost you about the same amount of money. Naturally, we consider the price category for used equipment.

We hope that our brief overview allowed you to draw the conclusions you need, stay ahead of us with a lot of different material and good luck!

This service and maintenance manual is intended for the universal mini loader MKSM 800. It is developed in accordance with the manuals for the maintenance and care of individual units of the MKSM 800 loader, technical specifications, as well as safety rules.

The manual contains technical data of the MKSM loader, a description of its design, instructions for servicing and caring for the machine, as well as lubrication, safety rules when working with the loader and its transportation. With proper observance of the instructions given in this manual, it is possible to avoid malfunctions and injuries, and therefore it is necessary that the personnel dealing with the MKSM 800 mini loader, before starting any work, are sufficiently familiar with the contents of this manual.

In view of continuous improvement of products and their parameters, the manufacturer reserves the right to make appropriate changes to the design of the MKSM 800 mini loader.

The universal mini loader MKSM is designed for loading, leveling and moving parods of classes 1-4 using the main bucket, digging narrow trenches, drilling holes in rocks of 1-2 classes using appropriate replaceable working equipment.

Technical characteristics of the mini loader MKSM 800

| Diesel engine | Zetor 5201.22 |

| View | Four-stroke |

| Cylinder diameter | 102 mm. |

| Piston stroke | 110 mm. |

| Compression ratio | 17 |

| Number of cylinders | 3 |

| Working volume of cylinders | 2696 cm3 |

| DIN power | 31.1 kW |

| StrAU power | 34.4 kW |

| Average fuel consumption | 6 l / hour |

| Idling speed | 600 +50 rpm. |

| The order of the cylinders | 1 - 3 - 2 |

| Onboard reducer | mechanical, cylindrical gears |

| Number of gearboxes | 1+1 |

| Weight of one gearbox | 169 kg. |

| Pump drive | mechanical, disconnected by means of a clutch |

| Hydraulic Travel Pumps | NPA 33 |

| Hydraulic Travel Motors | MPA 33 |

| Tires | 10,0/75 - 15,3 |

| Disks | 9 x 15.3 |

| Tire pressures | 0.392 Mpa |

| Steering | Mechanical |

| Implement hydraulic pump | U32l |

| Operating pressure | 16 Mpa |

| Hydraulic distributor | RSK 16 T3 |

| Hydraulic filter | H 22 |

| Continuous forward speed | 12 km / h |

| Maximum pulling force | 24 kN |

| Minimum turning radius with bucket | 2440 mm. |

| Working on a slope | 10 degrees |

| Parking brake brakes on a slope | 13 degrees |

| Overcome ascent of the path | 13 degrees |

| Boom lift | 5 sec. |

| Lowering the boom | 3 sec. |

| Bucket unloading at max. lifting height | 1.9 sec. |

| Theoretical duty cycle | 12 sec. |

| Rated lifting capacity | 800 kg. |

| Operating weight with bucket | 2851 kg. |

| Wasp transport weight with main bucket | 2711 kg. |

| Gross weight of MKSM 800 loader | 3700 kg. |

| Electrical voltage | 12 in |

| Accumulator battery | 2 x 12V |

| Battery capacity | 90 amperes |

| Generator, voltage and current | 14V x 55 amp. |

| Starter | 2.9 kW x 12V |

| Loader width MKSM 800 | 1680 mm. |

| Loader length MKSM 800 | 3270 mm. |

| Dina loader MKSM 800 without bucket | 2480 mm. |

| Loader height MKSM 800 | 2005 mm. |

| Track width | 1419 mm. |

| Maximum reach | 1370 mm. |

| Main bucket width | 1730 mm. |

| Maximum height of loader with bucket | 3700 mm. |

| Ground clearance | 206 mm. |

Refueling volumes of the mini loader MKSM 800

Technical description of units

The travel drive of the MKSM 800 mini loader is provided by a transmission with a Zetor 5201 diesel engine, which is rigidly connected to the pump drive and to the NPA 33 movement pumps and the U32l working equipment pump. ... The oil cooler of the hydraulic system and the radiator of the cooling system of the skid steer are located in front of the engine. The fuel tank is located on the right side, the hydraulic tank on the left side in the inner frame. The RSK16T3 distributor is located in front of the NPA 33 variable pumps under the hydraulic filter of the working fluid. To provide convenient access to individual units of the MKSM 800 loader, the safe type cab is tilted after preliminary disconnection of the hinges in the loader cab. The cab contains all controls and controls, instrumentation and the operator's seat. All this together forms a single assembly unit. The loader wheels are attached to final drives, which are fixed on opposite sides of the loader frame. Heating is located on the left side of the cab from the inside. The batteries are located on the right and left fenders. Access to them is possible after lifting the covers, which are equipped with a motorcycle lock.

Mini loader MKSM 800 is equipped with a Zetor 5201 diesel engine, which is elasticly installed. The engine is accessible from the rear after lifting the rear radiator shroud and from the top after tipping the bonnet and cab. It is a direct injection, four-stroke, three-cylinder, water-cooled diesel engine. The crankshaft housing is cast from gray cast iron, one-piece, with a flange for mounting the pump drive. The cylinder head is independent for each cylinder, the cylinder liners are replaceable.

The engine cooling system is liquid with forced circulation and with a thermostat. The circulating pressure lubrication system with a wet bath, the MKSM loader is equipped with a two-stage or replaceable oil filter. The fuel delivery system consists of a fuel pump, a mechanical all-speed regulator, and a fuel priming pump. The Zetor 5201 engine is cooled with a forced circulation liquid provided by a centrifugal pump mounted on the front of the engine crankcase and driven through a water pump via a V-belt drive. The cooling system includes a small circuit with a thermostat that quickly heats up the motor to an operating temperature of up to 80 degrees. The filler cap is located on top of the radiator, the coolant drain cock is located on the bottom left side of the radiator. The power supply system of the MKSM loader consists of a fuel tank, a fuel supply system on the engine and fuel pipes. The fuel tank is located on the right side of the rear with a filler neck behind the cab. The fuel tank has a capacity of 55 liters. From the bottom of the tank, fuel is sucked in by the fuel priming pump through the fuel line. A coarse fuel filter is installed on the lower part of the fuel priming pump. From the fuel priming pump, diesel is pumped into the Motorpal fuel pump through a single-stage fuel filter. The fuel pump delivers fuel through the high pressure pipes to the injectors. Excess fuel from the engine injectors flows back to the fuel tank via the return line.

MKSM 800 loader hydraulic system

Serves to drive the working equipment and the running gear. It consists of two hydraulic circuits: the implement circuit and the trolley drive circuit.

MKSM 800 working equipment contour

Consists of U32l pump, RSK16T3 three-section distributor, two hydraulic cylinders for raising and lowering the boom and two hydraulic cylinders for opening and closing the bucket. This circuit is protected by a pressure of 16 MPa at an engine speed of 1500 rpm by a safety valve on the RSK16T3 distributor.

MKSM 800 stroke drive circuit

Consists of two hydraulic pumps NPA 33 and two hydraulic motors MPA 33. This circuit is protected by a pressure of 35 MPa by means of high pressure safety valves built into the MPA 33 hydraulic motors. The working fluid tank, radiator and filter are common to both circuits. The hydraulic tank has a capacity of 55 liters.

Pump drive MKSM 800

Serves for the transmission of torque from the engine through the clutch to the adjustable pumps NPA 33, which ensure the movement of the loader by means of hydraulic motors MPA 33, as well as to the gear pump U32L, which serves to power the hydraulic cylinders of the working equipment.

The pump drive consists of a power take-off and a clutch, which together form one unit.

Controlling the pump drive is reduced to disconnecting it from the engine, especially to facilitate starting the engine at lower temperatures. This operation is performed mechanically with the clutch pedal located in the operator's cab.

The MKSM 800 loader drive is hydrostatic. The power unit is a Zetor 5201 diesel engine, the power of which provides optimal dynamic parameters of the loader during operation. The torque from the engine is transmitted through the flywheel and the clutch to the pump drive. The clutch is single-disc, disengaged with a pedal in the operator's cab. It serves to disconnect the pump drive in order to facilitate engine starting.

The pump drive crankcase is equipped with flanges for fastening two adjustable pumps NPA 33, which provide a drive for the chassis, and one gear pump U 32l, which fills the hydraulic system of the working equipment. From the adjustable hydraulic pumps, the torque is transmitted hydrostatically to the MPA 33 hydraulic motors by means of high pressure hoses. From the hydraulic motor, the torque is transmitted to the final drives by means of gears that are located between the hydraulic motors and the final drives. The design of the gear assembly allows the loader to be braked by the force of the Belleville springs. The loader is braked by means of a safety lever that is mechanically connected to the parking brake bypass valve when the safety ramp is folded back. The bypass valve allows pressurized oil into the drain branch of the hydraulic system (which releases the loader), causing the loader to brake. The raised safety arm protects against spontaneous or uncontrolled movement of the MKSM 800 loader.

MKSM 800 loader control

The control of the MKSM 800 loader differs structurally from the loaders produced at the present time. One-handed movement control - with the left hand, control of the working equipment, including the bucket, is carried out with the right hand.

Attention! When learning to operate the MKSM 800 loader, the levers and handles must be moved carefully. The clutch may only be used when starting the engine in cold weather, while the clutch can be depressed for a maximum of 1 minute. Never use the clutch while the engine is running. In this case, it threatens the destruction of the clutch with the bearing.

Starting the engine at low temperatures.

When operating the MKSM 800 loader in winter conditions, it is very important to change the oil and oil filter at the intervals recommended by the manufacturer, since it may happen that the viscosity of the oil increases during operation. Thus, the thickened oil flows around the engine oil filter when starting the engine, which ultimately means that the oil enters the engine without filtration. As a result, engine wear increases several times.

A prerequisite for starting the engine at temperatures below -5 is to replace the oil with 10W30, the cooling system must contain a liquid with a freezing point of -25 degrees. The hydraulic system must be filled with VMGZ oil.

It is recommended to build an electric antifreeze heater into the motor block on an external 220V power source, which preheats the coolant to a temperature that meets the summer operating conditions of the MKSM loader. It is recommended to turn on the dipped beam for a short time before starting. It is imperative to squeeze the clutches to disengage the hydraulic pumps and the pump drive.

For the purchase of the full version of the MKSM 800 loader maintenance manual, MKSM 800 spare parts, MKSM 800 repair, please contact our company.

The multipurpose municipal construction vehicle MKSM is one of the sales leaders in its segment, because technical characteristics, durability and performance of these machines are at a high level, and over the many years of using MKSM machines, users have been able to make sure of the reliability and durability of this model.

Scope of application of multipurpose municipal construction machines MKSM

Extremely wide: from small areas to industrial zones. The design features of these machines allow you to smoothly change their speed and direction of movement, turn around their own axis. The MKSM are most in demand in construction organizations, housing and communal services, road facilities, industry and transport. The popularity of this technique is explained by its combination of its versatility, which makes it possible to mechanize almost all communal, transport, construction, loading and earthmoving operations, its compactness and high maneuverability, which makes it possible to organize work in cramped conditions (in narrow aisles, enclosed spaces, in yard areas), where overall restrictions make the use of conventional techniques impossible.

The overall dimensions of the MKSM make it possible to penetrate even into openings 2.1 m high and 1.8 m wide. MKSM is ideal for the maintenance of sidewalks, footpaths, alleys, markets, when laying communications, road maintenance and landscaping.

In addition, the temperature range of MKSM operation is from -40 to +45, satisfying the needs of consumers in all climatic zones of Russia. MKSM models are equipped with modern diesel engines that meet European environmental standards. With regard to all manufactured modifications of the MKSM, the basic principle remains - to ensure maximum versatility of equipment, i.e. applicability in all major market segments, including by maintaining a wide range of quick-detachable attachments.

At the request of consumers, a set of attachments is supplied to MKSM: for loading (various buckets, forks and other equipment), cleaning (brush, blade, snowplow, etc.), earthmoving (drilling, excavator equipment), construction (concrete mixer) and others. works, including on soils with a low bearing capacity (in the case of installing a set of metal tracks on the MKSM, increasing the traction and coupling properties of the machine).

At the same time, it takes a little time to replace the working equipment - the equipment is equipped with a quick-acting clamp, which allows the operator to change equipment independently and without the use of additional tools.

Characteristics of the MKSM

| MKSM 800N | MKSM 800K | MKSM 1000 | |||

|---|---|---|---|---|---|

| Engine | |||||

| Model | HATZ 2M41 | HATZ 2M41 | HATZ 3M41 | CAMMINS А2300 | HATZ 3M41 |

| engine's type | diesel, four-stroke 2-cylinder |

diesel, four-stroke 3-cylinder | diesel, four-stroke | diesel, four-stroke 3-cylinder |

|

| Cooling system | air | air | water | air | |

| Rated power, kW (hp) | 27 (36) | 27 (36) | 36,8 (50) | 33 (44) | 36,8 (50) |

| Specific fuel consumption, g / kWh (g / hp h) | 220 (161,8) | 220 (161,8) | 220 (161,8) | 253 (186) | 220 (161,8) |

| Fuel tank, l | 50 | 50 | 50 | 50 | 50 |

| Preheater | auto | auto | auto | ||

| Performance characteristics | |||||

| Maximum lifting capacity, kg | 550 | 650 | 800 | 990 | |

| Maximum travel speed, km / h | 10 | 10 | 10 | 10 | |

| Overcoming rise, hail, no more | 13 | 13 | 13 | ||

| Heater | autonomous | autonomous dependent | autonomous | ||

| Overall dimensions, weight | |||||

| Length with main bucket, mm | 3200 | 3200 | 3270 | 3270 | |

| Machine width with tires, mm | 1400 | 1400 | 1680 | 1680 | |

| Track width, no more, mm | 1180 | 1180 | 1410 | 1410 | |

| Machine height by flashing light, mm | 2200 | 2200 | 2215 | 2215 | |

| Ground clearance, not less, mm | 200 | 200 | 206 | 206 | |

| Operating weight with the main bucket, mm | 2400 | 2400 | 2800 | 3400 | |

Attachments to MKSM for loading operations

Main bucket... Designed for loading and moving various cargoes - fertilizers, bulk materials (sawdust, shavings), snow, various types of soil. In addition, the bucket can be used as a blade for moving and leveling the soil.

Boom cargo... It is used for lifting, moving, loading and transporting bulky goods.

Cargo pin... It is used for moving, loading and transporting bulky goods (paper rolls, coils of wire, pipes).

Fork with clamp... They are used in construction, agriculture, in the arrangement of gardens, parks and in other sectors of the economy. They can be used when loading chopped off bushes, sawn trunks, branches, when working with straw, hay, silage, manure, scrap metal, rubble stone, pipes, scrap materials and other long loads.

Freight forks... They are used for transportation, warehousing and other cargo operations performed with stacked loads, boxes, pallets and other materials that can be stacked. Forks are used incl. in warehouses and customs terminals.

MKSM attachments for public utilities

Rotary blade... Designed for moving (raking and distributing) various materials when planning territories, for removing rocks and various granular and piece materials from sites, for backfilling trenches, as well as for cleaning the road from debris.

Sweeper... It is used for municipal works when cleaning industrial premises, yards, sidewalks, pedestrian paths and other areas with a hard surface from garbage, as well as for collecting dust, sand, dirt.

Road brush... It is used for cleaning and sweeping footpaths, squares, roads, sidewalks, courtyards and other areas with a hard surface.

Snow blower... Designed for cleaning freshly fallen and packed snow.

Spreader of deicing materials... It is intended for processing roads, streets, squares, airfields and other territories with special anti-ice materials.

Equipment for the MKSM for performing land works

Trench excavator... Designed for digging rectangular trenches in soils: light sandy clay, plant soil, peat, wet sand, fine gravel.

Bucket excavator... Designed for digging holes, pits, trenches in soils: light sandy clay, plant soil, peat, wet sand, fine gravel.

Ripper... Designed for loosening heavy, dense soils, including: clay, loam, cobblestone, frozen sand.

Drilling equipment... Designed for drilling wells with a diameter of 200, 300 and 400 mm in non-frozen soils of 1-4 categories (clay, vegetable soil, peat, raw sand, - fine gravel).

Attachments for construction work

Concrete mixer... Designed for the preparation of mobile concrete mixtures at various construction sites with a small amount of work at an ambient temperature of at least 5 ° C

The MKSM-800 loader is a multipurpose special equipment that is used in warehouses, construction works, and public utilities. The functionality of the loader depends on the attachment.

Despite its enormous capabilities, MKSM-800 has a small size, which allows the loader to be moved from site to site by truck and ensures uninterrupted operation in narrow aisles of warehouses. The loader can enter the room through a gate measuring 2.1 meters in height and 1.8 meters, and a volumetric hydraulic drive, which makes it possible to independently steplessly change the rotation speed of the right and left gearboxes, can turn the MKSM-800 on the spot, which makes it an excellent assistant when work in a warehouse.

The designers have done everything for the comfort of the driver. So in the cabin of the loader there are two hangers for outerwear, a box with the necessary tools, and the presence of vents, heating and thermal insulation will maintain a favorable temperature regime in any weather. All the main nodes of the MKSM-800 are located in easily accessible places. For example, if it is necessary to prevent or inspect the engine, it is enough just to open the rear hood, and for the same actions with the hydraulic system, it is enough just to raise and fix the cab.

The loader is equipped with different engines depending on the model. If this is a CUMMINS A2300 motor, made in the USA, then it gets to the name of the model "K" and is called MKSM-800K. And when the German HATZ 3M41 engine is installed, then the MKSM-800N. To change the functional purpose of the loader, the following attachments are produced: cargo forks, snow plows, road brushes, trench excavator, sweeper, cargo boom, drilling equipment, tracks, etc.

1 - hydraulic tank; 2 - capacitor; 3 - frame; 4 - cab heater; 5 - electronic control unit; 6 - freon pipelines with a receiver; 7 - evaporator; 8 - arrow; 9 - cockpit; 10 - joystick of electric control; 11 - main bucket; 12 - wheel; 13 - wing; 14 - storage battery; 15 - side chain transmission; 16 - hydraulic system; 17 - pump drive friction clutch; 18 - fuel tank; 19 - engine; 20 - radiator block; 21 - air conditioning compressor /

dimensions

Cabin

The cab is the operator's workplace. It contains all the controls, display systems to ensure proper working conditions for the operator. Installed on chassis 1 with silent blocks 5 at the front and tapered supports 2 at the rear.

Governing bodies

1 - friction clutch control pedal; 2 - fuel supply pedal; 3 - fuel supply lever.

Hydraulic system

The hydraulic system is used to drive the working equipment of the machine, replaceable

attachments and ensuring the movement of the machine. The hydraulic system consists of two circuits:

- the contour of the working equipment;

- the contour of the running gear.

1 - hydraulic motor; 2 - hydraulic pump; 3 - hydraulic valve; 4 - equalization valve; 5 - boom hydraulic cylinder; 6 - mesh filter; 7 - filler neck cover; 8 - filler neck; 9 - drain filter; 10, 16, 17 - quick disconnect connection; 11 - oil level sensor; 12 - hydraulic tank; 13 - drain plug; 14 - speed switching valve; 15 - bucket hydraulic cylinder; 18 - pressure filter.

Technical characteristics of the MKSM-800 loader

| TOTAL INFORMATION | ||

| PARAMETER | MKSM-800 | |

| Theoretical working cycle of loading with a bucket, s, no more | 12 | |

| Operating weight with main bucket, kg | 3245 | |

| Transport weight with main bucket, kg | 3100 | |

| Full weight of the car, kg | 4045 | |

| Hydraulic system pressure: - running, mPa - working equipment, mPa |

up to 350 |

|

| Hydraulic system performance: - running, l / min - working equipment, l / min - working equipment with additional pump, l / min |

49 |

|

| Maximum travel speed, km / h, not less | 18 | |

| Maximum static tipping load, N | 16000 | |

|

ENGINE |

||

| Brand | Cummins А2300 | |

| Type of |

diesel, four-stroke, four-cylinder |

|

| Rated power at rated speed engine crankshaft, kW, (hp) |

35,2 (48) | |

| Specific fuel consumption at rated speed engine crankshaft, g / kW × h (g / hp × h) |

253 (186) | |

| Maximum engine speed | 2800 | |

| Minimum engine speed per idle, rpm |

800 | |

|

POWER TRANSMISSION |

||

| Transmission (Japan) | chain drive | |

| Pumping unit (1 pc.) Manufactured by EATON (USA) | 558AK00085A | |

| Hydraulic motor with brake and drive sprocket (2 pcs.) made by EATON (USA) |

ADT31M24AA 208A0C | |

| Hydraulic distributor manufactured by EATON (USA) | AR1708-097 | |

| Leveling valve, manufactured by EATON (USA) | 39055-XXX | |

| Speed change valve, made by EATON (USA) | HF54753-09 | |

| Valve of the "High-Flow" function, made by EATON (USA) | – | |

| Tire | 10.0 / 75 - 15.3 Model F-201 PR6 TU 2521-027-00148984-98 | |

| Rim size | 9,0 – 15,3 | |

| Tire pressure, kPa (kgf / cm 2) | 240 ± 25 (2.4 ± 0.25) | |

|

The tires are suitable for work on low load-bearing soil |

||

|

Electrical equipment |

||

| Rated voltage of electrical equipment, V | 12 | |

| Grounded | on the case | |

| Rechargeable battery (2 pcs.) | 6ST-90A or 6ST-90AP | |

| Voltage, V | 12 | |

| Capacity, A. h | 90 | |

| Generator | comes with engine | |

| Rated voltage, V | 14 | |

| Maximum current, A | 45 | |

| Starter | comes with engine | |

| power, kWt | 2,2 | |

| Voltage, V | 12 | |

|

WIPER |

||

| Electric gear motor (2 pcs.) | 476.3730 | |

| Electric washer (2 pcs.) | 124.5208 | |

|

LIGHTING DEVICES |

||

|

Front road headlight |

||

| Left (1 pc.) | 05.0895.0000 LH RHD | |

| Right (1 pc.) | 05.0894.0000 RH RHD | |

| Left (1 pc.) | 05.1101.000 LH | |

| Right (1 pc.) | 05.1102.000 RH | |

| Rear working light (1 pc.) | 05.1102.000 RH | |

| Plafond | BAAF.453754.001 | |

|

LIGHTING AND TRAFFIC SIGNALING DEVICES |

||

|

Back lamp |

||

| Left (1 pc.) | 02.1244.0000 LH | |

| Right (1 pc.) | 02.1245.0000 RH | |

| Sound signaling device (2 pcs.) | 201.3721-01 | |

| Flashing beacon (1 pc.) | "Agent-12U" AG 11.000 | |

|

INSTRUMENTATION AND MEASURING DEVICES |

||

| Operating time counter | SVN2-01-3.1 | |

| Hydraulic oil pressure switch | K4-SP-C-F-3 / 10U / P1 | |

| Engine coolant temperature sensor | 2M02V003 | |

| Receiver for coolant temperature gauge engine |

U06620028 | |

| Engine oil pressure switch | comes with engine | |

| Fuel level indicator sensor | DT7.3-900 | |

| Fuel level indicator receiver | U06620021 | |

| Hydraulic oil temperature sensor | 2M02V003 | |

| Hydraulic oil temperature gauge receiver | U06620035 | |

| Oil drain filter clogging sensor hydraulic systems |

comes with filter | |

| Pressure oil filter clogging sensor hydraulic systems |

comes with filter | |

| Hydraulic oil level sensor | LVE 3 | |

|

VOLUME OF FILLED LIQUID BY SYSTEMS, l, not less: |

||

| Cooling system | 12 | |

| Crankcase | 6,5 | |

| Fuel tank | 75 | |

| Hydraulic system | 75 | |

| Onboard gearboxes | 2x9 | |

Video review of the MKSM-800 loader