Appointments of the komatsu d65 bulldozer ex 12. Komatsu D65E bulldozer (technical characteristics)

Hitachi Caterpillar Doosan XCMG

Special equipment JCB, Komatsu, Caterpillar, Hitachi, Doosan, XCMG

Bulldozer Komatsu D65

Bulldozer Komatsu D65 with economical engine

Installation of a SIGMA blade and an automatic transmission with a torque converter lock-up clutch on the new D65 bulldozer made it possible to achieve high performance and fuel economy.

The SIGMA blade, developed on the basis of an innovative approach to excavation, has provided a significant increase in labor productivity.

The new Komatsu D65 transmission with high efficiency has significantly reduced fuel consumption. Compared to conventional models, this Komatsu bulldozer is more fuel efficient.

The choice of automatic or manual mode of gear shifting, depending on the type of work being performed, is easily carried out by pressing the switch on the multifunctional control system unit (in neutral position).

Automatic gear shift mode for Komatsu D65 bulldozer

Used for general dozing work. When the load increases, the lower gear is automatically engaged, when there is no load, the Komatsu D65 gearbox automatically shifts to the highest gear to ensure maximum travel speed.

This load-dependent torque converter lock-up mode reduces fuel consumption and improves performance on a one-to-one basis.

Manual gearshift mode for Komatsu D 65 bulldozer

This mode is used for bulldozing and loosening hard rock. The transmission will automatically downshift under load, but no upshift occurs when the load is removed.

Economical Komatsu D65 Bulldozer Electronic Engine

The Komatsu SAA6D114E engine delivers 155 kW (207 hp) at 1,950 rpm. The economical, powerful Komatsu engine makes the D65 a top-notch bulldozer for loosening and dozing.

The engine meets US EPA Tier 3 and EU Stage 3A emission standards.

The Komatsu D 65 is equipped with a turbocharger, direct fuel injection and charge air cooling for maximum power, fuel efficiency and emission compliance. To reduce noise and vibration, the engine is mounted on the main frame using rubber mounts.

Komatsu D 65 bulldozer gearbox gearbox with ECMV valve (electronically controlled modulating valve)

Depending on the travel conditions, the controller automatically adjusts the engagement of each clutch, ensuring its smooth, shock-free engagement, as well as increasing the service life of the units and creating comfortable conditions for the operator's work.

Komatsu D 65 hydrostatic steering system - smooth, fast turn

When cornering, Komatsu D65 dozer engine power is transmitted to both tracks without interrupting the power flow to the inner track, allowing the machine to turn smoothly and quickly. Counter-rotation is provided at the smallest turning radius for increased maneuverability.

Settable gear shift pattern for Komatsu D65 bulldozer

When choosing an automatic gearshift scheme

Joystick electronic control system of movement of the bulldozer komatsu D 65

The hydraulic joystick controls blade / ripper operation. Combined with a highly reliable hydraulic system, it achieves high control precision.

Komatsu D 65 Bulldozer Cab with Integrated ROPS

The new Komatsu D65 bulldozer cab features an integrated ROPS design based on computer simulation. The robust and sealed cab significantly reduces operator noise and vibration and prevents dust from entering the cab.

Ease of control in a comfortable environment. In addition, the lack of external ROPS and struts has improved lateral visibility. This allowed for excellent visibility.

Blade with a variable angle of rotation and tilt of the Komatsu D65 bulldozer

Komatsu D65 Dozer Dozer Dozer Dozer Variable Angle and Tilt Dozer with Heavy Duty Box Frame is optional. This blade is used on the EX, WX and PX models.

The hydraulic pivot and tilt function of the blade expands the practical use of the machine and increases its productivity in a wide variety of applications. Manually adjusting the blade tilt angle also enhances operational capabilities and increases efficiency.

Preventive maintenance is the best way to ensure equipment longevity. Therefore, the Komatsu D65 is designed with convenient service points for quick and easy inspections and maintenance.

Komatsu D 65 Parallel Link Undercarriage (PLUS)

The parallel link undercarriage system of the Komatsu D65 bulldozer features rotating bushings that are highly durable under all operating conditions.

Free rotation of the bushings effectively reduces bushing wear, which results in twice the life of the undercarriage compared to conventional undercarriage. In addition, the wear limits for the link and carrier roller are also increased, which corresponds to the extended bushing life.

Idler wheel support with automatic adjustment of Komatsu D65 bulldozer

The self-adjusting idler support ensures that a constant spring force is applied to the idler guide, eliminating play in the idler. This in turn reduces noise and vibration and extends the life of the wear plate.

Komatsu D 65 bulldozer main frame design

The simple design of the main frame increases its strength and reduces stress concentration at critical points. The frame of the crawler bogie has a large cross-sectional area, a pivot pin is installed on it, which made it possible to increase the reliability of the machine.

Hydraulic Piping Protection - The tilt cylinder tubing is located inside the push bar to protect it from damage.

Komatsu D65 Bulldozer Modular Power Train Design

Komatsu D65 power train components are housed in sealed modules that can be removed and installed without oil leaks and allowing maintenance to be carried out quickly, smoothly and cleanly.

Komatsu D 65 Non-Adjustable Disc Brakes - Wet disc brakes do not require adjustment and have a long service life.

Technical characteristics of the Komatsu D65 bulldozer

Komatsu SAA6D114E-3 engine- 4-stroke, water-cooled and direct fuel injection

Suction type - turbocharged and charge air cooled

Number of cylinders - 6

Diameter and piston stroke - 114 × 135 mm

Working volume - 8.27 l

Regulator - all-mode, medium speed range, electronic

Komatsu engine power:

Gross: 155 kW (207 hp)

Net: 153 kW (205 hp)

Rated speed - 1 950 rpm

Fan drive - hydraulic

Lubrication system - Forced lubrication driven by a gear pump

Full-flow filter

Net Power @ Maximum Radiator Fan Speed 139 kW (186 HP)

Gearbox of the check point of the bulldozer komatsu D 65

The Komatsu TORQFLOW transmission consists of a three-piece, single-stage, two-phase, water-cooled torque converter with lock-up clutch and a planetary gearbox with hydraulically actuated multi-plate clutches.

The gearbox of the Komatsu D65 bulldozer gearbox has a forced lubrication system for optimal cooling. The shift lock lever and neutral lock switch prevent accidental machine movement.

Gear Forward Reverse

1st gear 3.6 km / h 4.4 km / h

2nd gear 5.5 km / h 6.6 km / h

3rd gear (low speed) 7.2 km / h 8.6 km / h

3rd gear 11.2 km / h 13.4 km / h

Steering system for Komatsu D65 bulldozer

Lever PCCS for driving in all directions. Moving the PCCS lever forward moves the machine forward; moving the lever backward moves the machine in reverse.

To swing to the left, tilt the PCCS lever to the left. To pivot to the right, tilt it to the right. The hydrostatic steering system of the Komatsu D65 bulldozer (HSS) is provided by the planetary gear, hydraulic pump and hydraulic motor. It is also possible to perform a counter-rotating rotation.

The Komatsu bulldozer has oil-cooled, multi-disc, spring-loaded, pedal-operated steering brakes with hydraulic release. The parking brake can also be engaged with the gear shift lock lever.

Minimum turning radius

komatsu bulldozer D65EX-16 - 1.9 m

bulldozer Komatsu D65EX-16 with PAT blade - 2.0 m

Komatsu bulldozer D65PX-16 - 2.2 m

bulldozer Komatsu D65WX-16 - 2.1 m

Undercarriage of the Komatsu D65 bulldozer

Suspension - oscillating type with balancer and kingpin

Track frame - high-strength monoblock design with large cross-sectional area

Track Rollers and Idler Wheels - Lubricated Track Rollers

Komatsu D65 Bulldozer Track Shoes - Lubricated tracks. The ingenious design of the dust seal prevents abrasive substances from entering the clearances between the pins and bushings, thereby prolonging the life of the tracks. Track tension is easily adjusted with a grease gun.

Blade type - SIGMA blade / Blade with variable angle of rotation and skew

Number of track rollers (on each side) - 7

Shoes Type (Standard) - Single Grouser

Number of shoes (on each side) - 42

Grouser height, mm - 65

Shoe width (standard), mm - 510/560

Support surface area, cm2 - 30395 (30295) / 33375 (33265)

Ground pressure (tractor), kPa (kgf / cm2) - 55.2 (56.4) / 0.56 (0.58) / 52.9 (54.0) 0.54 (0.55)

Track width, mm - 1 880/2 050

Supporting length of tracks, mm - 2 980 (2 970)

Komatsu D65 bulldozer final drives

A two-stage reduction gear with spur and planetary gears increases traction and reduces stress on the gear teeth, extending the life of the final drives. The drive sprocket segments are bolted for easy replacement.

Hydraulic system of the Komatsu D65 bulldozer

The Closed Center Load Sensing System (CLSS) is designed to provide fast and accurate control as well as efficient workflow when combining operations.

Komatsu D 65 bulldozer hydraulic control mechanism :

All slide valves are installed externally, next to the hydraulic tank. Piston hydraulic pump with a capacity (discharge flow) of 248 l / min at the rated engine speed.

Relief valve actuation pressure - 27.9 MPa 285 kgf / cm2

Control valves:

Spool valves for "SIGMA" blade or blade with adjustable tilt

Working positions:

When lifting the blade, raise, hold, lower and float

When the blade is skewed to the right, hold, to the left

Variable angle and tilt blade spool valves

Working positions:

When lifting the blade, raise, hold, lower and float when the blade is tilted to the right, hold, to the left

When turning the blade to the right, hold, to the left

Optional control valve for multi-shank ripper (EX, WX)

Working positions: when raising the ripper, raise, hold, lower

Komatsu D 65 bulldozer hydraulic cylinders- piston, double-acting

Komatsu D65 blade lift cylinder (diameter) - SIGMA blade / Adjustable tilt blade - 85 mm (Variable angle blade and tilt blade - 90 mm)

Blade tilt cylinder (diameter) - SIGMA blade / Adjustable tilt blade - 125 mm (Variable tilt and tilt blade - 130 mm)

Blade swing cylinder Komatsu D65 (diameter) - Blade with variable swing angle and tilt - 110 mm

Ripper lift cylinder (diameter) - SIGMA blade / Adjustable tilt blade - 125 mm (Adjustable tilt and swing blade - 125 mm)

Hydraulic oil volume (when changing): 55 l

Ripper Equipment (Extra Capacity): 7 L Multi-Shank Ripper

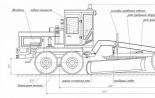

Dimensions of the Komatsu D 65 bulldozer with a SIGMA blade (D65EX-16) and shoes with one grouser.

Dimensions Komatsu D65 Bulldozer with Variable Angle and Tilt Dozer (D65EX-16) and Single Grouser Shoes.

Bulldozer equipment Komatsu D65

Operating weight of the bulldozer Komatsu D 65

Tractor Weight: Includes ROPS cab, lubrication, coolant, hydraulic control, full fuel tank, operator and standard equipment.

D65EX-16 - 17,120 kg (17,430 kg)

D65PX-16 - 18,890 kg (19,210 kg)

D65WX-16 - 17,860 kg (18,170 kg)

D65EX-16 - 18,030 kg (18,340 kg)

D65PX-16 - 18 870 kg (19 210 kg)

D65WX-16 - 18,900 kg (19,210 kg)

Operating Weight - Includes SIGMA Blade (EX / WX) or Adjustable Tilt Blade (PX) or Variable Angle and Tilt Blade, ROPS cab, operator weight, weight of standard equipment, nominal volumes of lubrication systems, coolant, machinery hydraulic control, the weight of the full fuel tank.

D65EX-16 - 19,510 kg (19,820 kg)

D65PX-16 - 20,990 kg (21,310 kg)

D65WX-16 - 20 360 kg (20 670 kg)

Komatsu D 65 bulldozer with a dozer with a variable angle of rotation and tilt

D65EX-16 - 20,990 kg (21,300 kg)

D65PX-16 - 21,860 kg (22,200 kg)

D65WX-16 - 21,890 kg (22,200 kg)

Komatsu D65 Bulldozer Standard Equipment

Air filter, two-element, with clogging indicator

Alternator, 60A / 24V

Rechargeable batteries, 140 Ah / 2 × 12 V

Engine speed retarder pedal

Engine hood

Gull-wing engine side covers

Hydraulically driven radiator fan with cleaning mode

Locks, filler caps and shields

Muffler with profiled exhaust pipe

Fittings for measuring oil pressure in power train assemblies

Reinforced hinged radiator guard

Expansion tank for radiator

Rear counterweight (EX, WX with PAT blade)

Back cover

Adjustable seat

Starter, 7.5 kW / 24 V

Steering system: HSS (Hydrostatic Steering System)

Track roller guards, center and end sections (PX)

Track Roller Guards, End Sections (EX, WX)

Track Chain Assembly - Sealed and Lubricated Heavy Duty Track Chain

510mm Single Grouser Shoe (EX)

560mm Single Grouser Shoe (EX with PAT)

760mm Single Grouser Shoe (WX)

760mm single grouser shoe (PX, WX with PAT blade)

915mm Single Grouser Shoe (PX)

Bottom guard: oil pan and heavy duty gearbox

Water separator

ROPS cab

Air conditioning

Air conditioner intake air filter

The Komatsu D65E-12 is a heavy-duty mining crawler bulldozer. The model belongs to the thrust class 10-12. This technique is used to move massive volumes of soil over short distances. Komatsu D65E-12 is suitable for the construction of dams, dams, backfilling of trenches, grading of dirt roads or embankments, soil removal and leveling of soil surfaces.

The Komatsu D65E-12 is a heavy-duty mining crawler bulldozer. The model belongs to the thrust class 10-12. This technique is used to move massive volumes of soil over short distances. Komatsu D65E-12 is suitable for the construction of dams, dams, backfilling of trenches, grading of dirt roads or embankments, soil removal and leveling of soil surfaces.

Despite the clearly expressed focus in the field of application, the bulldozer is a fairly versatile technique. Quite often, Komatsu D65E-12 is used in repair and construction work on roads, in the construction of canals or construction of real estate, in mining and clearing a strip of trees and stumps. The model received a wide range of interchangeable equipment: extenders, rippers, slopes, openers and other devices. This has significantly expanded the scope of the Komatsu D65E-12 and has a positive impact on efficiency in various jobs.

Komatsu products are the highest quality machinery with an unusually long service life and unrivaled performance. The D65E-12 is distinguished by its well thought out ergonomics of the working area, ease of maintenance and the highest profitability in any field of use. The model will be especially useful in technological processes where continuity plays a decisive role. Komatsu uses its own power pack for its bulldozers. The hydraulic drives, transmissions and motors installed in the equipment of the Japanese manufacturer are developed and manufactured on site, which ensures a long service life and unsurpassed quality of Komatsu products.

In the D65E-12, the high performance is due to the new direct injection engine.

- The Komatsu bulldozer with a mass of 19.78 tons has a specific ground pressure of 55.9 (0.57) kPa (kgf / cm2).

- The model is quite large in size: height - 3165 mm, width - 3460 mm, length - 6660 mm.

- The capacity of the D65E-12 blade is 3.55-5.61 cubic meters.

- The wheelbase is 2675 mm, the wheel track is 1880 mm.

- Komatsu D65E-12 is equipped with a 180-horsepower engine that can reach speeds of 13.4 km / h.

- The fuel consumption of the Komatsu D65E-12 model is 180 g / kWh, and the fuel tank holds up to 406 liters.

Engine

Komatsu D65E-12 is equipped with a 4-stroke diesel engine model 6D125E with liquid cooling, direct injection, standardized exhaust gas composition and natural suction. The engine power is 190 (159) hp. (kW), speed - 1800 rpm. Among the analogues, the D65E-12 is considered the most economical bulldozer.

The power of the unit is fed to the final drives through a torque converter. This process is highly efficient. The 6D125E meets the latest global environmental requirements, despite its high power and performance. The access to the check of the engine and its components is facilitated thanks to the side doors, which are opened by the action of a gas spring cylinder.

Device

The track carrier frame, swing axles, and flat bottom frame give the Komatsu D65E-12 excellent maneuverability in sticky and wet terrain and prevent dirt from sticking to the frame.

The modular design of the power train allows units to be installed or removed at maximum speed. Multi-disc brakes, operating in oil, extend service life by eliminating the need for maintenance during operation and adjusting the brake band. Thanks to the straight body frame made of thicker plate, Komatsu has been able to reduce the number of component parts, which has a positive effect on the model's reliability. For maximum durability, the manufacturer has reinforced the box blade back beam and increased the track frame cross section.

Almost all Komatsu bulldozers (including the D65E-12) are equipped with a Torkflow hydromechanical transmission. It provides smooth gear shifting under load. You can change the direction of movement or change gear using the multifunction joystick. He is also responsible for controlling the turn of the bulldozer. The planetary gear-hydraulic motor and brake-clutch function allow the machine to move smoothly, even when cornering. If the operator needs to change the route, he moves the joystick to the left or forward. The driver uses the wrist to change gears. The machine instantly responds to a change in the position of the joystick.

Comfortable and smooth movement in the Komatsu D65E-12 was achieved thanks to the installation of hydraulic valves and components of the power train on the frame with the use of shock-absorbing pads.

The basic equipment of the model includes an adjustable seat with a comfortable backrest. Free movement of the fuel control lever and 3-stage height adjustment of the armrests provide a comfortable working environment for the operator. Dust does not penetrate into the Komatsu D65E-12 cab due to excessive pressure inside it and the use of air filters. The modernized cab design has a positive effect on visibility.

Price

The Komatsu D65E-12 bulldozer is not cheap at all. It will not be possible to buy this used equipment for less than 3 million rubles in adequate condition. The average cost of a model is 3.3-3.5 million rubles. The new bulldozer costs over 10 million rubles.

The company "Naftakom Group" renders services for renting a modern, universal, high-performance bulldozer Komatsu D65EX-15.

This type of special equipment is intended for use in the mining industry (in the extraction of minerals), for road construction works, as well as in the construction of any objects, buildings and structures. The Komatsu D65EX bulldozer easily copes with the following types of work:

- planning, clearing, cleaning of territories;

- the production of excavations in the ground of any volume and nature - trenches, pits, ditches;

- creation of embankments (dams, dams);

- construction of earthen cloths for automobiles and railways;

- demolition of buildings.

Komatsu specialized construction equipment is characterized by such qualities as reliability, versatility, productivity and the ability to work in difficult climatic conditions (at ambient temperatures down to -50 degrees).

Renting a bulldozer from a well-known Japanese company will allow you to solve all the production problems facing the tenant.

Bulldozer Komatsu D65EX - a powerful machine from the best manufacturer

The Komatsu D65 bulldozer demonstrates high efficiency when working with soil, coal, crushed stone, gravel and other materials. Komatsu D65 is capable of excavating all types of soil, transporting it, creating embankments when working on a construction site, in mining, in mines or quarries.

Bulldozer specifications:

- weight in working order - 20.31 t;

- engine power - 142 kW;

- speed - 10.6 km / h;

- front blade-blade width - 3.97 m.

The main advantages of the Komatsu D65 bulldozer:

- To reduce fuel consumption, the developers have designed the installation of a modern gearbox with increased efficiency.

- A hemispherical blade with variable tilt angle and an automatic transmission with a hydraulic transformer lock-up clutch gave the machine high performance and reduced fuel consumption.

- The steering of the bulldozer is easily accomplished by installing a hydrostatic system.

- The machine is equipped with a modern Komtrax system, a fan for lowering the temperature of the motor with a hydraulic drive and the possibility of reversing.

- Convenient and understandable control system.

- Reduced noise and vibration of the power plant.

- Minimal environmental impact of exhaust gases and compliance with international standards, making this model suitable for urban use.

The Komatsu D65 bulldozer is equipped with an improved undercarriage. It has parallel links, which are a proprietary Japanese manufacturer, and rotating bushings, which are characterized by increased wear resistance regardless of operating conditions. Also, this model of the bulldozer has a turbocharged engine of increased power and a three-shank ripper.

Advantages of renting special equipment in Naftakom Group

Having been in the specialized equipment rental market for many years, our company provides the most profitable and attractive conditions for hiring Komatsu D65. We can offer our clients:

- the optimal cost of renting a bulldozer;

- almost any rental period (from several hours);

- fast delivery of rented special equipment to the customer's site;

- provision of the services of an experienced bulldozer operator;

- individual approach when concluding a lease agreement;

- the ability to use a rented bulldozer throughout Russia.

If you have decided to rent a Komatsu D65, contact our qualified managers who will answer all additional questions and help you place an order. Contacts for communication are indicated on our website.

Among the main advantages of the Komatsu D65EX bulldozer, the manufacturer names an automatic transmission with a torque converter lockup, a Komatsu SAA6D114 engine and a Sigma blade.

Photo source: komek.ru

Specifications Komatsu D65EX-16, weight

The blade is designed to cut and move soil with the front of the blade. The result is an increase in the capacity of the working body and a decrease in cutting resistance. The movement of the soil is carried out more evenly. All this improves productivity by 15%.

The used transmission helps to reduce fuel consumption by 10% by selecting the optimal speed range for specific operating conditions. When working in the normal speed range, the torque converter lock-up mechanism is automatically engaged and power is transmitted directly to the transmission.

Photo source: komek.ru

Photo source: komek.ru

You can select Power (P) or Economy (E) mode. In the second case, at the output you get power, which is enough to carry out specific work. In particular, this is relevant when performing work with movement down the slope, leveling operations, etc. Switching between modes is performed on the control panel.

Engine

The Komatsu D65EX-16 bulldozer is equipped with an electronically controlled SAA6D114E-3 engine, which is the company's own development. The powertrain design includes a turbocharger, direct fuel injection and charge air cooling. The installation of the diesel engine on the main frame is made with the use of rubber cushions, thereby the developers have achieved a reduction in the level of noise and vibration. The radiator fan speed is electrically controlled.

Cab and controls

The control system is also the development of Komatsu specialists, it is called PCCS. There are separate joysticks to control the blade / ripper (hydraulically driven) and move the machine. The operator is required to make a minimum of effort.

For the Komatsu D65EX-16 bulldozer, two gear shift modes are available: automatic and manual. The use of the former is recommended by the manufacturer for standard work. In this case, the inclusion of a lower gear when the load increases and the transition to a higher gear when there is no load occurs automatically, which helps to save time with repetitive operations. In manual mode, the lower gear is also engaged automatically, but when the load drops, operator intervention is required.

Photo source: komek.ru

Photo source: komek.ru

Special attention is paid to smooth cornering performance. When driving, engine power is transmitted to both tracks, so there is no interruption to the power flow on the inner track. In addition, there is a counter-rotation function, which is useful when the turning radius is small.

The cab is mounted using dampers (instead of rubber mounts) to reduce shock and vibration. Blades with adjustable swivel / tilt angle are available on special order.

Dimensions (with Sigma blade)

Maintenance Komatsu D65EX-16

The Komatsu D65EX-16 operator has a large color monitor at his disposal. The side doors of the engine compartment can be folded up, the opening angle is increased. Wiring and controller connectors are made using sealed connectors. The power train is modular in design: the components are housed in sealed modules for easy removal and installation. Wet disc brakes require no adjustment.

Japanese equipment is rightfully considered advanced in many respects, and the technical characteristics of the Komatsu D65 bulldozer once again prove that the Japanese miracle of technology surpasses foreign counterparts in many functions. By the way, for the first time the whole world started talking about the company only 100 years ago, when a small plant appeared on the territory of Japan in the suburbs of Tokyo, which in a few decades will become the largest industrial giant in the special equipment industry. Today the enterprise employs about 33 thousand employees who produce not only the Komatsu D65E bulldozer, but also other industrial-grade special equipment.

Characteristics of the use of special equipment

Considering the technical characteristics of the Komatsu D 65 bulldozer, it can be noted that the technique allows you to perform a fairly large front of earthmoving production tasks, regardless of the complexity and labor intensity of the task. The main industries where the equipment is used are the construction segment, quarrying, mining and processing and other areas. The technical characteristics of the Komatsu D 65 bulldozer allow you to perform the following types of work:

- Moving to ground distances.

- Loosening and milling of the soil.

- Planning and technological leveling works for production sites.

- Erection of earth embankments, as well as embankments of sand and other soil structures.

- Digging production trenches or foundation pits, followed by backfilling.

- Clearing any territories, areas from rubble and debris.

- Snow removal from roadways.

Komatsu d65 bulldozer at work

General technical characteristics of the bulldozer Komatsu D65E 12:

How a car motor works

Not the least important for the car is the installation of the propulsion system, on which a 6-cylinder four-stroke engine is installed, which belongs to the serial class SAA6D114E-3. For this group of engines, direct fuel injection is provided, which is provided by an additional direct cooling system. According to the main technical characteristics, the Komatsu D65EX 16 bulldozer consumes 180 g / kWh of fuel. The power unit complex has the following parameters for the controls of the Komatsu D65 bulldozer:

Features of working comfort for the driver

The cab of the machine has a reinforced version, which provides additional protection options for the operator of special equipment. The cabin interior is equipped with additional protection systems to prevent moisture and dust ingress. Additionally, protective screens are installed that reduce the noise level inside the cab, thus the operator practically does not feel the operation of the motors, which negatively affect the hearing.

For comfortable control, a joystick is installed inside the cab, and a special technological operator's workplace is also equipped. Convenient control in hot and cold seasons is provided by air conditioners, heating and ventilation systems, which have an innovative solution. Better visibility and visibility is ensured through the implementation of panoramic glazing inside the car.

General device and design

As the main frame for the bulldozer, a suspended frame made of special durable steel grades is used. For the frame used in the tracked vehicle, special metal structural elements and blanks with a dimensional cross-section are used. The undercarriage of the machine is equipped with a special tracked link of increased strength, which has self-lubricating characteristics, where up to 39 belt links with increased overall dimensions are provided. This factor allows the bulldozer to move comfortably and without problems on land plots that have a difficult geographic relief.

For the supports that are used in driving wheels, an automatic adjustment is provided, which ultimately guarantees a long service life of specialized equipment in various conditions of the machine's use. In addition, the supports reduce such negative factors as noise and vibration.

Positive and negative aspects of special equipment

Like any type of transport, the Japanese manufacturer's bulldozers have their negative and positive sides. So, the plus are:

- All parts and components of the machine have high technical parameters from a direct manufacturer.

- High power parameters compared to the same class of machines.

- Fuel consumption is one of the lowest.

- Excellent maneuverability, even in confined working conditions.

- Simplicity and ease of operation and maintenance.

- The special equipment meets the highest international requirements for environmental operation.

There are practically no drawbacks, but it is expressed only in the high cost of the car. If you are renting a car, the Japanese brand's bulldozer does an excellent job, while its cost pays for itself up to 100% in a record short period of time. An additional disadvantage is maintenance, which requires the use of expensive spare parts and lubricants. Otherwise, the Komatsu D 65 bulldozer has only positive aspects of performance.

Machine modifications

For all the time, the Japanese manufacturer did not make any modifications to the car, as he believed that this line could not have additional modification series. Along with this, the manufacturer introduced some variations of the current model:

- Komatsu D65 E Series

- Komatsu D65 EX Series. This series allows the use of a rotary blade. In general terms, the car does not differ from the basic model.

- Komatsu D65 A series. In this range, the blade can be adjusted according to the main parameters of the machine.

Summing up, it can be noted that the variations of special equipment differ only in the operational part of the blade, which is used for specific technological work.

Conclusion

As mentioned above, one of the disadvantages of a bulldozer is its price. In Russia, they know that the very high cost of special equipment completely covers all the costs associated with earthmoving work. According to statistics, Komatsu D 65 least of all requires maintenance and repairs, so the demand for a car remains quite high not only in Russia, but also in countries of far and near abroad. The manufacturer makes technical changes to the controls almost every year, equipping them with electronics and other "smart" fillings that allow the bulldozer operator to easily manage the most sophisticated special equipment of our time.

Date of publication:

similar articles

ospetstehniki.ru

Komatsu D65 - Bulldozer Specifications

Heavy crawler dozers are used in many industries. The bulldozer does an excellent job with various types of ground work. One of these bulldozers is the Komatsu D65. This machine is in great demand due to its manufacturability and high productivity.

Features of the machine

The Komatsu D65 bulldozer has several features that distinguish it from machines of other manufacturers in the same class. These include:

- Availability of specialized cab protection. It protects the operator from injury in the event of a possible overturning of equipment.

- Chassis. The extended base of the machine and the increased width of the tracks make it easy to keep a heavy tracked vehicle on an incline.

- The bulldozer is electronically controlled. The operator controls complex machinery with just two joysticks.

- Automatic adjustment of the fluid temperature in the cooling system of the power unit.

- The ability to install dumps of various shapes and methods of adjustment.

- Panoramic glazing of the cab, allowing the operator to maintain an all-round view, eliminating the occurrence of "dead" zones.

- Double noise insulation of the cab protects the person from distracting extraneous sounds, makes the work comfortable.

- Easy access to all equipment nodes. This allows you to quickly eliminate the malfunctions of any node.

- Heating of all windows in the cab prevents them from fogging up in any weather conditions.

Purpose of Komatsu D65 and its modifications

The Komatsu D65 bulldozer, like other machines in this class (for example, the Shantui 16SD), is designed for a wide range of earthmoving operations. Thanks to the high-quality materials from which the bulldozer is made and its high technical characteristics, the bulldozer fulfills the assigned tasks, regardless of the hardness of the soil. He can perform the following types of work:

Overall dimensions of Komatsu D65

- creation of artificial embankments from soil, sand, and other similar materials;

- digging of various types of pits, filling them;

- leveling of unpaved areas on terrain with difficult terrain;

- the movement of soil masses at the required distance;

- cleaning the roadway from snow drifts.

During the entire existence of the Komatsu D65 bulldozer, the manufacturer has not released any of its modifications, but the bulldozer is manufactured in three versions. The differences between these models are only in attachments, which in the name are indicated by an alphabetic index (A, E, EX).

The Komatsu D65 bulldozer can be equipped with the following attachments:

- U-shaped fixed and rotary blade, with the ability to adjust the angle of its skew;

- swivel blades with the ability to adjust the skew;

- loosening units that allow you to perform tasks of loosening and milling the soil;

- attachment for pipe laying;

- blade-mounted scoring knives.

Bulldozer equipment Komatsu D65 - table of characteristics

Due to its versatility, the bulldozer is widely used in various fields of activity, such as: industry, construction, mining, etc. It has proven itself well when cleaning the territory from various blockages.

Bulldozer characteristics

Komatsu D65 has the following characteristics:

- The dimensions of the special equipment are 6600x3100x3460 (length, width, height).

- Fully loaded weight- 19750 kg.

- Ground pressure is 570 g / cm 2.

- Power plant power- 207 horsepower.

- Number of gears- 3 front, 3 rear.

- Fuel tank volume- 405l.

- Distance between tracks- 1880 mm.

- Power unit- six-cylinder, four-stroke turbocharged diesel engine.

- Engine volume- 8.3 liters.

- Inner diameter of the cylinder- 114 mm.

- Piston stroke- 135 mm.

- Maximum speed- 13.4 kilometers per hour.

- Crankshaft rotation- 1950 rpm in one minute.

- Brake system- tape type.

- Dump volume- 5.6 cubic meters.

Komatsu D65 - maintenance

Engine parameters, machine device

The power plant of the Komatsu D65 bulldozer has direct fuel injection and liquid cooling. Antifreeze is used as a coolant. This engine model is distinguished by its economy, consumes only 180 kW / h.

Power unit Komatsu D65

The operator's cab is completely sealed. It is equipped with air conditioning and heating. Working in a bulldozer becomes comfortable at any ambient temperature. The operator's station plays an important role in comfort. The control levers are positioned so that you do not need to reach for them.

Operator's Station Komatsu D65

The salon has a comfortable chair. Its height and backrest angle are adjustable. The armrests also have the ability to adjust. Thus, absolutely anyone can customize the seat for themselves.

The Komatsu D65 is operated using joysticks. One of them is responsible for the movement of special equipment, the second for the control of attachments. The technique is very sensitive to even the slightest deflections of joysticks. This makes its movement and the work of the attachment smooth. Thanks to electronic control, the bulldozer is highly maneuverable.

The Komatsu D65 has self-lubricating tracks. Their vibration is reduced by additionally installed rollers that prevent the track from bouncing vertically. In addition, 7 rollers are installed on each track, which reduce chassis wear. The increased width of the tracks and the lengthened base of the vehicle make it stable on embossed surfaces.

Pros and cons of a bulldozer

Like any other technique, the Komatsu D65 bulldozer has its advantages and disadvantages. The pluses of this machine include:

Advantages of the Komatsu D65 bulldozer

- High quality materials, used in the manufacture. All parts are resistant to wear, therefore, the bulldozer works practically without breakdowns.

- High efficiency. With comparatively low fuel consumption, Komatsu does an excellent job. This, undoubtedly, distinguishes it among the equipment of this class.

- Ease of maintenance. All nodes can be reached without much difficulty.

- High environmental friendliness. Emissions of harmful substances into the atmosphere do not exceed generally accepted world standards.

- Good maneuverability even in the most difficult conditions.

Despite all its advantages and high technical characteristics, this special equipment has two drawbacks: the high price of the machine (it is directly related to the quality and wide scope of the special equipment) and the cost of maintenance (Japanese-made parts, as well as consumables, are quite expensive).

From the above, it follows that the Komatsu D65 bulldozer is a heavy tracked vehicle. Despite its high cost, it has many advantages, is in demand among buyers, and is used in various fields of activity.

Related video: Diagnostics of the Komatsu D65PX-15 crawler bulldozer

specnavigator.ru

Komatsu d65e-12: specifications

Bulldozer equipment of 10-12 class is widely used in various fields of activity: economic, construction, road-building, industrial, mining.

Komatsu d65e-12 is indispensable both when performing construction works of the zero cycle, and for use in various technological processes at industrial enterprises. The unit has established itself as predictable in operation, easy to operate, it is equipped with modern power plants, and has a variety of deliveries. All-season, designed for most climatic zones. Komatsu d65e-12 will be an excellent choice for those who are engaged in construction, industrial or business activities.

Komatsu d65e-12 is interesting for its increased resource, due to the use of various innovative solutions using various composite materials. A flexible and well-thought-out system of equipment for the base model will allow you to choose exactly what you need. An example is a machine equipped with an additional soil ripper. When installed on the base model, the driver's cab is additionally re-equipped for new equipment.

History of creation

Komatsu is a well-known global brand of tractor equipment manufacturer. In fact, the company was founded in 1921 and was engaged in the repair of construction equipment. Most of the team that founded the company has been trained in Europe and the United States of America. By the beginning of the 30s, the company began producing the first prototypes of tracked vehicles.

The history of the construction of Komatsu bulldozer equipment began in the post-war period. In 1947, the D50 was the first bulldozer produced. It was with this class of technology that the inhabitants of the Far East and the northern regions of the Soviet Union got to know in Soviet times. The equipment of this manufacturer was actively purchased in the early 60s, before the appearance of similar equipment of domestic production.

Later, special-purpose equipment was purchased, for example, class 4 bulldozers, which had just begun to be designed in domestic design bureaus, pipelayers, forestry equipment, loaders, mining units, presses and much more. Komatsu equipment was actively used in the construction of the BAM, in the development of minerals in Yakutia and Siberia. It has found application in our days, being considered one of the world's best manufacturers.

The only representative of Komatsu in the post-Soviet space is the subsidiary of this corporation "CIS Komatsu" with headquarters in Moscow. The firm confirmed its interest in the Russian market in 2010 by opening a Komatsu Manufacturing Rus plant in Yaroslavl.

This article will focus on the popular Komatsu d65e-12 bulldozer tractor model.

Specifications

Komatsu d65e-12 belongs to thrust class 10-12. With a mass of 16 tons, it is capable of speeds up to 12 km / h. The unit is intended for the preparation and planning of construction sites, for the preparation of road surfaces. It can also be used in the mining industry, in large warehouses of bulk building materials. Equipped with a ripper, the Komatsu d65e-12 can be used in difficult soils.

The Komatsu d65e-12 bulldozer is equipped with a comfortable operator's cab, the most lightweight control system. Japanese technology is known for its automated troubleshooting system and operating unit resource management system. The D65e-12 is capable of performing work in various climatic conditions fully satisfying the requirements of our latitudes. It is worth noting the maximum visibility from the operator's cab.

Overall weight indicators

The overall dimensions of the Komatsu d65e-12 bulldozer are as follows:

- dump capacity 3.55-5.61 cubic meters

- bulldozer weight 15 620 kg

- track 1.88 m wheelbase 2675mm

- overall dimensions 3165x3460x6660mm

Engine

The unit is equipped with a water-cooled direct injection four-stroke diesel engine. 6D125E with a speed of 1950 rpm on the flywheel, with a power of 135 kW and a flow rate of 180 g / kW per hour, is considered one of the economical engines of the traction class 10-12, it allows developing a maximum torque of 799 Nm at 1100 rpm. Equipped with a forced lubrication mechanism. Low noise level and compliance with all modern environmental requirements, allows it to be used in urban environments.

Transmission

The Komatsu d65e-12 bulldozer is equipped with a TORQFLOW Komatsu transmission. It is a three-element, forced liquid-cooled, single-stage, single-phase torque converter. Hydraulic planetary gearbox with multi-plate clutch is devoid of the flaws of manual transmissions. To increase the resource, the box is forcibly lubricated, removing excess heat. The box allows you to work with three forward and three reverse gears. Control is performed by joysticks. For safety reasons, the unit is equipped with locking levers.

The final drive is made in the form of planetary and spur gears, minimizing the possibility of transmitting shock effects to the power train. Using the experience of past years, we have segmented the gear wheel, which makes it easy to change damaged segments in the field.

The bulldozer is controlled by a joystick. Light movements in the desired direction allow you to efficiently drive a 16 ton machine. This is achieved through the advantages of using hydraulic clutch and braking systems. The minimum turning radius for impressive dimensions is only 3.2m.

Chassis

The undercarriage of the Komatsu d65e-12 bulldozer consists of a pair of caterpillar belts, a suspension, support rollers, track rollers mounted on a track frame. Balance bar swinging suspension with front-mounted rolling axles. The structure is equipped on each side with carrier rollers, between them there are 7 carrier rollers on each side. The caterpillar consists of 39 links. The link connections are made using a unique technology that prevents abrasive materials from entering the connections.

The frame with a flat bottom is designed in such a way that when working on sticky soils, it prevents the build-up of dirt under the frame. The braking system is represented by multi-disc brakes operating in an oil bath.

Cabin. Bulldozer control

When working on the Komatsu d65e-12 bulldozer, the operator is maximally unloaded: a comfortable working chair, ventilation and air conditioning system, increased visibility of the control cabin - all this makes the operator's work as easy as possible.

The bulldozer is easily controlled with a joystick specially developed by Kamatsu. The joystick clearly reacts to the operator's actions and with its help the bulldozer is able to easily maneuver over the work surface.

One of the design advantages of this model is good shock absorption and low noise level. The control cab is easily customizable for the operator and contains active protection against dust penetration into the interior of the cab. The basic model of the unit can be equipped with a reinforced cab if additional operator protection is required.

Blade control is virtually invisible to the operator at varying speeds and material quantities, allowing accurate material handling. This effect has been achieved through the use of CLSS technology in the production of the hydraulic blade system. This is expressed in smooth compensation of direct impacts of the material into the dump.

Convenient and sophisticated electronic fault detection system makes troubleshooting easy. This, in turn, allows you to control the resource of the bulldozer as a whole and its parts.

Experience in operating a bulldozer. Advantages and disadvantages

The Komatsu d65e-12 bulldozer is manufactured by one of the world leaders in the production of bulldozer equipment. All units are patented and designed by KOMATSU. The units are high-tech, expensive, but easy to replace and maintain; there is a fault detection and control system.

The operator feels comfortable working in various climates. All the most critical components are well thought out and protected from external influences. A number of Komatsu service centers operate in the Russian Federation.

Standard delivery

If we talk about the delivery of the unit, then it is standard and includes the following elements.

Optional equipment

Additional equipment that is used when working with a bulldozer includes:

- Wear-resistant caterpillar belt (made of dream-repellent composite materials)

- Additional cooling fan with possible reversal

- Front hook

- Drawbar

- Systems for working cab heating and de-icing

- High footrests

- Air purification system

- Additional work lights for the cab

- Protective grille for radiator

- Rigid drawbar

- Suspended high back seat

- Comfortable office chair with fabric cover

- Full-length skid plate for rollers

- Armored bottom shield for heavy duty

- Anti-vandal protection for the dashboard

- Ripper multi-shank

Conclusion

In conclusion, we can say that if you need a reliable modern bulldozer for work, you should stop at the choice of this model. Its greatest strengths can be considered the compliance of the d65e-12 with most standards in the field of safe and environmental use, low noise characteristics, excellent and comfortable handling, a computer diagnostics system and the quality of parts, the use of composite materials to improve performance. This is an uncompromising option, requiring, if necessary, maintenance on the basis of a service center certified by the manufacturer.

The high price of service and the cost of both the unit itself and the components can stop you from buying the presented bulldozer. We can add to the above the fact that one of the gold mining companies in Russia has been using this model of a bulldozer for a long time. The closest and only major competitor of Komatsu in the global market is Caterpillar, Inc.

tractorreview.ru

Bulldozer Komatsu d65e-12 - Construction portal

The Komatsu D65E-12 is a heavy-duty mining crawler bulldozer. The model belongs to the thrust class 10-12. This technique is used to move massive volumes of soil over short distances. Komatsu D65E-12 is suitable for the construction of dams, dams, backfilling of trenches, grading of dirt roads or embankments, soil removal and leveling of soil surfaces.

Despite the clearly expressed focus in the field of application, the bulldozer is a fairly versatile technique. Quite often, Komatsu D65E-12 is used in repair and construction work on roads, in the construction of canals or construction of real estate, in mining and clearing a strip of trees and stumps. The model received a wide range of interchangeable equipment: extenders, rippers, slopes, openers and other devices. This has significantly expanded the scope of the Komatsu D65E-12 and has a positive impact on efficiency in various jobs.

Specifications bulldozer Komatsu D65E-12 |

|

| Bulldozer weight, kg | 15620 |

| Operational weight, kg | 19780 |

| Minimum turning radius, mm | 2200 |

| Komatsu D65E-12 bulldozer engine | |

| Model | Komatsu 6D125E |

| Type of | four-stroke, liquid-cooled, with standardized exhaust gas composition, with direct fuel injection and natural intake |

| Air supply | turbocharging, followed by air cooling |

| Flywheel power at 1950 rpm, h.p. | 180 |

| Number of cylinders | 6 |

| Piston diameter, mm | 125 |

| Piston stroke, mm | 150 |

| Working volume, l | 11.04 |

| Refueling tanks of the Komatsu D65E-12 bulldozer | |

| Fuel tank, l | 406 |

| Engine cooling system, l | 52 |

| Engine crankcase, l | 38 |

| Final drive (on each side), l | 24 |

| Transmission, bevel gear and side clutches, l | 48 |

| Hydraulic system of the Komatsu D65E-12 bulldozer | |

| Pump type | gear |

| Maximum flow, l / min | 180 |

| Safety valve setting, MPa | 20.6 |

| Hydraulic cylinders | piston, double-acting |

| Hydraulic system capacity | |

| With a hemispherical blade and tilt hydraulic cylinders, l | 55 |

| With straight blade and tilt cylinders, l | 55 |

| With a variable angle of rotation and skew, l | 55 |

| With multi-shank ripper, l | 55 |

| Undercarriage of the Komatsu D65E-12 bulldozer | |

| Suspension | swinging, with a balance bar, with front-mounted swing axles |

| Crawler frame | load-bearing, large section, solid construction |

| Track shoes | lubricated track joints |

| Number of shoes (each side) | 39 |

| Grouser height, mm | 65 |

| Shoe width (standard), mm | 510 |

| Support area, cm 2 | 27285 |

| Number of track rollers (each side) | 7 |

| Number of carrier rollers (each side) | 2 |

| Specific ground pressure (only bulldozer), KPa (kgf / cm 2) | 55.9 (0.57) |

| Track track, mm | 1880 |

| Overall length of a caterpillar on the ground, mm | 2675 |

Bulldozer KOMATSU D65E-12

Engine of the bulldozer KOMATSU D65E-12

The powerful 6D125E naturally aspirated diesel engine delivers 190 hp of power output. The engine power is transmitted through a torque converter to the final drives with high efficiency. The engine meets the requirements of modern emission standards without compromising the power and performance of the machine. The side doors of the engine, opening upward under the action of a gas spring cylinder, provide free access for checking the engine and its components.

Cab of the bulldozer KOMATSU D65E-12

If the operator wants to steer the machine forward and to the left, he moves the joystick forward and to the left. If the operator wishes to change gear, he flexes the wrist. The machine obediently responds to joystick positions, giving the operator the confidence to operate the machine with the Komatsu joystick.

For smooth and comfortable ride, the power train components and hydraulic valves are mounted to the frame using shock-absorbing rubber pads to dampen vibration and absorb noise. Since the KOMATSU D65E-12 uses joysticks, the operator's compartment is free for easy entry or exit. An adjustable seat with backrest is included with the base machine.

Three-stage armrest height adjustments and fuel control lever movement provide comfortable operation and free leg position.

The use of air filters and the creation of excess air pressure inside the cab of the KOMATSU D65E-12 dozer prevents dust from entering the cab. In addition, the new cab design provides excellent visibility in all directions. The oil-filled cab suspension damper cushions impacts for improved ride comfort and extended component life.

Thanks to the CLSS load sensing closed center hydraulic system, blade control travel is directly proportional to blade speed, regardless of load and travel speed. Thus, excellent precise handling is achieved.

Standard equipment of the KOMATSU D65E-12 bulldozer

1. Air cleaner with double filter element and clogging indicator

2. Alternator 35 A

3. Batteries, 140 Ah / 2 x 12 V

4. Cooling fan

5. Retarder pedal

6. Panel of the electronic control system

7. Engine hood

8. Side doors of the engine

9. Lighting system (includes two front and two rear lights)

10. Single-lever machine control system

11. Muffler with profiled exhaust pipe

12. Flat radiator guard door

13. Back cover

14. Rollover Operator Protective Structure (ROPS) Mounting Stands

15. Starter, 7.5 kW / 24 V

15. Traffic control system

17. Adjustable seat

18 Track roller guards, rear sections (E)

19. Track assembly with shoes

20 510 mm (20 in) wide single grouser shoes

21. Bottom shields of the oil pan and transmission

DOWNLOAD A detailed description of the Komatsu d65e-12 Bulldozer

stroydocs.ru

Bulldozer Komatsu D65 (Komatsu)

- Content:

- Design features

- Operator's cab

- Power unit

- Travel speed

- Chassis

- Operational dimensions

The Komatsu Heavy Bulldozer with Ripper is effective in loosening and moving soil. Its qualities are most widely disclosed in the mining industry and at processing plants.

The Komatsu Heavy Bulldozer with Ripper is effective in loosening and moving soil. Its qualities are most widely disclosed in the mining industry and at processing plants.

Design features

Constant improvement by the team of designers of units and assemblies of manufactured equipment is the reason for such popularity of the Komatsu D65 bulldozers. Among the latest improvements that increase its reliability and comfort, we note:

- Undercarriage for stability of the machine when working on sloping ground. Achieved by reducing the location of the drive and installing wider tracks of increased length;

- Fan, cooling the engine radiator with a unique hydrostatic switching drive, working in automatic mode. Rapid adjustment of the coolant temperature, saves fuel and extends the service life of the power unit. Has a reversing mode used to clean the radiator from dirt;

- The control amplification system of the Komatsu 65 bulldozer is based on the use of hydrostatics. Allows you to apply the same force to the steering wheel to turn and control the machine on soils of different densities and in different operating conditions;

- Completion with new dumps that exceed the volume of dumps of previous generations.

Operator's cab

In a sealed, with a double noise-insulating layer, the operator's cab provides conditions for safe and full-fledged work. Air filters are installed. A separate compressor blows air into the cabin, creating an excess pressure in it to block the penetration of dust from the outside. The Komatsu bulldozer cab is installed on damping supports, which with great efficiency smooth out the inevitable vibration and shock loads. The hexagonal shape allows you to observe the working process without distorting objects arising from observation through the glass of a conventional quadrangular cab. Other interesting aspects of the cockpit, which received the project name "Space Cab ™", are:

- High performance air conditioner;

- A control system in which the functions of changing the movement and control of the blade are implemented by one lever, such as a joystick;

- For the operator's convenience, the chairs have height-adjustable armrests;

- Heated glasses.

Power unit

The engine installed on the Komatsu D65 bulldozer uses a microprocessor-based control system for complete fuel burnout in the combustion chamber. The presence of an on-board system that monitors the optimization of the processes of ignition and combustion of fuel made it possible to increase the power output. Reduce the consumption of diesel fuel and the release of solid particles into the atmosphere. The engine is marked SAA6D114E-3. It is a turbocharged diesel. Develops a power of 210 hp. Working volume 8250 cm³. Single row design with six combustion chambers. The piston stroke is 135 mm. Diameter 114 mm.

The Komatsu TORQFLOW transmission fitted to the Komatsu 65 dozer is equipped with a locking lever and a switch to prevent the machine from rolling away accidentally when left on uneven ground. Three gears provide six speeds: three forward and three reverse.

Travel speed

|

Broadcast |

Forward speed |

Reverse speed |

|

III (km / h) |

Chassis

Lowering the center of the drive on the Komatsu D65E, combined with the use of increased link heights on the tracks, improves ride performance. Another positive aspect that makes work easier is the ability to fully see the blade knife for the operator. Much attention has been paid to the fight against vibration. Vibration characteristics are reduced due to:

- two upper rollers installed on each side and preventing the tracks from jumping in the vertical direction when driving;

- Seven double-sided road rollers keep the chassis in an optimal position, reducing wear.

The Komatsu D65E bulldozers are equipped with self-lubricating tracks with a standard length and height of 65 mm lugs with a total support area of 32,940 cm³. The shoe width is 620 mm. The toothed-type drive wheels are segmented. The segments are bolted together. This innovation saves time spent on removing and replacing it in case of failure in working conditions. This design allows for the most efficient use of equipment on normal and hard ground.

The undercarriage on the Komatsu D65PX bulldozer is designed to operate in soft, sagging soils. Its guide wheels are slightly shifted forward to increase the contact area, which is now 60,120 cm³. The number of road wheels has reached 16 pieces. Shoe width increased to 920 mm.

Operational dimensions

Dimensions are for Komatsu D65PX with blade installed.

stroy-plys.ru

Komatsu D65EX - specification, photo, video, description

- Type of: Bulldozers;

- Manufacturer: KOMATSU;

- Model: Komatsu D65EX.

Komatsu D65EX photo

Komatsu D65EX description

Among the main advantages of the Komatsu D65EX bulldozer, the manufacturer names an automatic transmission with a torque converter lockup, a Komatsu SAA6D114 engine and a Sigma blade.

The blade is designed to cut and move soil with the front of the blade. The result is an increase in the capacity of the working body and a decrease in cutting resistance. The movement of the soil is carried out more evenly. All this improves productivity by 15%.

The used transmission helps to reduce fuel consumption by 10% by selecting the optimal speed range for specific operating conditions. When working in the normal speed range, the torque converter lock-up mechanism is automatically engaged and power is transmitted directly to the transmission.

You can select Power (P) or Economy (E) mode. In the second case, at the output you get power, which is enough to carry out specific work. In particular, this is relevant when performing work with movement down the slope, leveling operations, etc. Switching between modes is performed on the control panel.

The Komatsu D65EX-16 bulldozer is equipped with an electronically controlled SAA6D114E-3 engine, which is the company's own development. The powertrain design includes a turbocharger, direct fuel injection and charge air cooling. The installation of the diesel engine on the main frame is made with the use of rubber cushions, thereby the developers have achieved a reduction in the level of noise and vibration. The radiator fan speed is electrically controlled.

The control system is also the development of Komatsu specialists, it is called PCCS. There are separate joysticks to control the blade / ripper (hydraulically driven) and move the machine. The operator is required to make a minimum of effort.

For the Komatsu D65EX-16 bulldozer, two gear shift modes are available: automatic and manual. The use of the former is recommended by the manufacturer for standard work. In this case, the inclusion of a lower gear when the load increases and the transition to a higher gear when there is no load occurs automatically, which helps to save time with repetitive operations. In manual mode, the lower gear is also engaged automatically, but when the load drops, operator intervention is required.

Special attention is paid to smooth cornering performance. When driving, engine power is transmitted to both tracks, so there is no interruption to the power flow on the inner track. In addition, there is a counter-rotation function, which is useful when the turning radius is small.

The cab is mounted using dampers (instead of rubber mounts) to reduce shock and vibration. Blades with adjustable swivel / tilt angle are available on special order.

The Komatsu D65EX-16 operator has a large color monitor at his disposal. The side doors of the engine compartment can be folded up, the opening angle is increased. Wiring and controller connectors are made using sealed connectors. The power train is modular in design: the components are housed in sealed modules for easy removal and installation. Wet disc brakes require no adjustment.

The Komatsu D65EX-16 bulldozer, in addition to the version with the EX index, has modifications called D65WX and D65PX.

Models similar in their capabilities include: John Deere 850J LT, Caterpillar D6R XW (Series II), Komatsu D65E-12.

The design of the bulldozer is based on a supporting frame with increased rigidity, made of special grades of steel. The frame of the caterpillar cart is made of metal blanks with an increased cross-section.