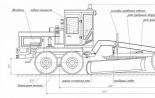

Motor grader dz 98 overall dimensions. Motor graders

The DZ 98 motor grader is a special technique that is used for large-scale excavation and grading operations, in the construction and maintenance of roads on soils of 1-4 categories.

The manufacturer has provided various attachments in the configuration, significantly expanding the technological capabilities of the DZ-98 grader. On the rear hitch, you can install a ripper-scarifier, with which the driver of the motor grader loosens the soil. An additional wing can be installed on the grader blade, which allows the snow mass to be thrown onto the side of the road during snow removal. An optional side blade allows snow to be cleared behind fences.

All the main functions of the D3-98 motor grader are performed with the help of a special working body, which is a blade with a knife mounted on the machine frame and powered by a diesel engine. They can perform the functions of lowering, lifting, turning in a vertical and horizontal plane.

This motor grader has excellent maneuverability and a change in the angle of installation of the blade in planes, and the blade can also be taken out to the side.

In order to increase labor productivity and improve the working conditions of the operator in this technique, containing the main frame, balancers, automatic control system of the blade position, the working body and proportional sensors. In addition, an additional sensor is mounted on the second balancer.

The motor grader has a wide range of interchangeable working equipment (swivel dozer blade, side grader blade, rear ripper).

Transmission

Serves to transfer torque from the engine to the driving wheels of the DZ 98 motor grader and allows you to change the value and direction of this moment, as well as to disconnect the engine from the driving wheels. In addition, the transmission is used to take off power to drive the hydraulic pumps. It consists of the following mechanisms:

- hydraulic pump drive reducer;

- clutch;

- gear boxes;

- transfer gearbox;

- parking brake;

- cardan transmission of the front axle drive;

- cardan transmission of the drive of the rear and middle axles.

The hydraulic pump drive gearbox, clutch, gearbox, transfer gearbox and parking brake form a single unit, hereinafter referred to as a transmission unit. The transmission unit is connected to the flywheel housing of the engine by means of a centering collar on the gearbox housing of the hydraulic pump drive. The transmission of torque from the engine to the transmission is carried out through a special elastic coupling consisting of an outer coupling half, twelve rubber pins, spring rings and an inner coupling half.

Bridges

The rear and middle axles of the DZ 98 motor grader are interchangeable. Each of these bridges is a steel beam, in the middle part of which the main gear bracket is attached with bevel gears with a circular tooth installed on it, and final drives are attached to the flanges. Fully balanced half-shafts connect the main gear to the final drives. The final drive is a spur gear with internal gearing. The small drive gear of each final drive is connected to the corresponding axle shaft by means of a drive bush and a flange. Each final drive is equipped with a pneumatic multi-disc wheel brake. The brake discs are in an oil bath. The bridges are attached to two balancers with ball and cylindrical pins. This fixing allows the installation of bridges.

Front axle

The front axle of the DZ 98 motor grader is driving and steerable. All its main parts are similar to those of the rear and middle axles, with the exception of the elements that ensure the rotation of the wheels and attachment to the main frame. The cast beam of the front axle has welded cast heads at the ends. In the middle of the beam along the longitudinal axis of the motor grader, two fingers are fixed, located on one axis. On these pins, the front axle can pivot relative to the main frame in the transverse plane. Fully balanced axle shafts. At the ends of the axle shafts, forks of a double cardan joint are attached, due to which the torque is transmitted to the final drive, which has a turn in the horizontal plane. The final drives are similar to those installed on the rear axles and differ only in the absence of wheel brakes and the ability to rotate relative to the axle beam in the horizontal plane. They are interconnected by a steering transverse rod, with the help of which the toe-in of the front wheels is adjusted.

Grader blade

To expand the scope of the DZ 98 motor grader, the following additional equipment is installed on it:

- scarifier;

- bulldozer equipment;

- loosening equipment;

- track-laying equipment;

- snow removal equipment.

All kinds of additional working equipment are located on the head of the main frame of the motor grader. Track-laying equipment is designed for the development and movement of soils up to category IV inclusive when performing the following works:

- road construction and maintenance;

- layout on the ground;

- clearing snow on roads and off roads with a snow depth of up to 1.2 m;

- cutting off bushes;

- excerpt of foundation pits.

Track laying equipment

Consists of a central blade and two wings hingedly connected to it.

The central blade is connected through the lugs to the hydraulic cylinder rod, with the help of which the entire blade is raised and lowered. Blade wings can be set in track-laying, bulldozer and right or left grader positions with the help of two hydraulic cylinders. If necessary, one wing can be in the track-laying position, and the other in the bulldozer position. The rotation of the wings around the vertical axis occurs when the rods of the hydraulic cylinders are extended. Suspension of track-laying equipment is similar to suspension of bulldozer and ripping equipment.

Ripping equipment

Consists of ripper and suspension. The ripper is a cast beam, into the windows of which five teeth with replaceable tips are inserted. The tips are attached to the teeth with a pin that is secured with a cotter pin. Suspension of ripping equipment is similar to that of bulldozer equipment

Snow clearing equipment

Designed for clearing roads, airfields and other areas from snow by moving or throwing it aside. The conical surface of the frontal blade of the blade allows you to clear the roadway from snow at low speeds by shifting it to the side during the longitudinal movement of the motor grader. At higher speeds, snow is thrown to the side, while being distributed at a distance of up to 15 m, which leads to the absence of snow banks along the road bed

Bulldozer equipment

Designed for the development and movement of soil, excavation, backfilling holes, trenches, snow clearing and other auxiliary work. Soils of categories I and II are developed without preliminary loosening, soils of category III and higher, as well as frozen soils are developed in a preliminary loosened state. Bulldozer equipment consists of a blade and a suspension, which includes a push frame, rods and a hydraulic cylinder for raising and lowering the blade

Scarifier

Designed for the development of dense soils up to category IV inclusive, loosening worn-out road surfaces, breaking the crust of frozen soil. The scarifier is a cast frame, into the windows of which five teeth with replaceable tips are inserted. With the help of rods, the scarifier is attached to the head of the main frame of the motor grader, and with the help of lugs, to the lifting and lowering hydraulic cylinder.

Technical characteristics of the DZ 98 motor grader

|

Total information motor grader DZ-98 |

|

| Motor grader class | |

| Width (with blade in transport position), mm | |

| Height (without flashing beacons), mm, no more | |

| Longitudinal base, mm | |

| Front wheel track of the grader, mm: | |

| Narrow | |

| broad | |

| Rear wheel track of the grader, mm: | |

| Narrow | |

| broad | |

| Ground clearance of the grader, mm: | |

| under the blade in transport position | |

| under the front axle | |

| under the rear axle | |

| under the suspension of the middle and rear axles | |

| Motor grader weight, kg: operational | |

| front axle | |

| attributable to the middle and rear axles | |

| Static ground load at operating weight, N (kgf): | |

| on a blade mounted perpendicular to the longitudinal axis | |

| on the scarifier's teeth | |

| The number of gears of the DZ-98 grader: | |

| when moving forward | |

| when moving back | |

| The speed of the motor grader at the rated speed of the engine crankshaft, km / h: | |

| when moving forward: | |

| I transfer | |

| 2nd gear | |

| III gear | |

| IV transfer | |

| V gear | |

| VI gear | |

| when moving backward: | |

| I transfer | |

| 2nd gear | |

| III gear | |

| IV transfer | |

| V gear | |

| VI gear | |

| Minimum turning radius when driving on dry concrete surface, m |

|

| The slope of holding the grader with the parking brake,%, not less | |

| Braking distance of a motor grader moving at an initial speed of 30 km / h on a horizontal section of dry asphalt with the clutch disengaged, m, no more | |

| Braking distance of a motor grader moving at an initial speed of 30 km / h when braking by an emergency system (in case of failure of one of the circuits), m, no more | |

|

DZ-98 engine |

|

| Type of |

diesel |

| Model |

YaMZ-238NDZ Cummins M- 11C265 |

| Rated power, kW (hp) |

173 (240) 202 (275) |

| Rated speed, rpm | |

| Start |

starter |

|

Transmission |

|

| Type of |

mechanical, with all-wheel drive, with a front axle disengagement mechanism |

| Hydraulic pump drive reducer |

single row with flexible coupling |

| Clutch |

dry, two-disk, permanently closed with hydraulic maintenance of its drive, with a brake on the driven shaft |

| Transfer gear |

single row for driving the middle and rear axles with parking brake |

| Parking brake |

belt type |

| Intermediate gears to bridges |

gimbals |

|

Chassis |

|

| Wheel formula | |

| Leading bridges | |

| Steering bridge |

front |

| Main gear of bridges |

single-stage, tapered, no differentials |

| Final drive axles |

single-stage, cylindrical, with internal gearing |

| Half-shafts |

fully unloaded type |

| Wheel brakes |

multi-disc with sintered discs operating in an oil bath |

| Middle and rear axle suspension |

balancer with reaction rods, providing pumping of bridges in the vertical plane |

| Front axle suspension |

articulated, providing pumping of the bridge in the transverse plane |

| Tire size, inch |

16.00-24 or 20.5-25 |

| Tire pressure, MPa (kgf / cm2) |

0,23…0,28 (2,3…2,8) |

|

Work equipment (DZ-98 motor grader) |

|

|---|---|

|

Track paving |

|

| The volume of a prism drawing in a bulldozer position, m3, not less |

|

| The width of the blade in the track position, mm, no more |

|

| Blade height, mm, not less | |

| Main cutting angle when bulldozing blade position |

|

| Blade angle back and forth from the bulldozer position in the plan, not less |

|

|

Bulldozer |

|

| The volume of the drawing prism, m3, not less | |

| Blade width, mm, not less | |

| Blade height, mm, not less | |

| Lowering the blade below the support surface, mm, not less |

|

| Blade main cutting angle | |

|

Loosening |

|

| Number of teeth of ripping equipment | |

| Maximum deepening of the ripper tooth equipment, mm, not less |

|

| Capture width of ripping equipment, mm, not less |

|

|

Grader blade |

|

| Blade length, mm, not less | |

| Blade height with knives, mm, not less | |

| Cutting angle | |

| The angle of cleaning the slopes at an angle of capture in the plane of the slope is not less than 45 ° | |

| Cuvette depth, m, not less | |

| inner wall slope |

from 1: 2 to 1: 3 |

| outer wall slope |

from 1: 1 to 1: 1.5 |

| Angle of installation in the horizontal plane, full-turn blade | |

| The angle of the part-turn blade from the position perpendicular to the longitudinal axis of the DZ-98 motor grader | |

| Side extension of the blade in both directions relative to traction frame, mm, not less |

|

| Lowering the blade below the supporting surface, mm, not less | |

|

Additionally |

|

|

Control |

|

| Gearbox control, multiplier, reverse and front axle |

mechanical |

| Clutch control |

mechanical with hydraulic maintenance |

| Front wheel steering |

hydraulic |

| Brake control: | |

| wheeled |

pneumatic |

| parking |

mechanical |

| Working bodies management |

hydraulic |

|

Electrical equipment |

|

| Voltage, V | |

| Starter power, kW (hp) | |

| Rechargeable batteries: | |

| type of | |

| number | |

|

Filling tanks capacity |

|

| Fuel tank of the grader, l | |

| Engine cooling and heating system, l | |

| Engine lubrication system, l | |

| Hydraulic system of the grader, l | |

| Gearbox, hydraulic pump drive gearbox, transfer gearbox, l | |

| Main gear of rear, middle axles (each), l | |

| Main gear of the front axle, l | |

| Onboard axle reducer, l | |

| Wheel brake, l | |

| Anti-freeze fuse, l | |

| Blade rotation reducer, l | |

|

Technical and economic indicators |

|

| Hydraulic system working fluid consumption, g / engine hour, not more | |

| Specific fuel consumption, kg / m3, no more | |

|

Reliability indicators |

|

| 80% resource before the first overhaul, engine hours, not less | |

| Mean time between failures, engine hours, not less | |

| Technical utilization factor, not less | |

| Specific total operational labor intensity of periodic technical maintenance, e.h / motohour, not more | |

| Operational labor intensity of the shift technical service, person / hour, no more |

|

|

Ergonomics indicators |

|

| Temperature at the driver's workplace, ° С: | |

| not less | |

| at a relative humidity of 40-60%, not higher | |

| at relative humidity 60-80%, not higher | |

| for areas with an average air temperature of 13 hours hot month, exceeding plus 25 ° С, not higher |

|

| Efforts on the controls, N (kgf), no more: | |

| on the steering wheel when the DZ-98 motor grader moves at a speed of at least 8 km / h on a horizontal section with a dry, hard, even surface | |

| on the engine control pedal | |

| on the control levers of the implements used in each working cycle | |

| on the control levers of the machine used when moving it by its own motion | |

| on pedals like brake | |

| on levers and pedals used no more than five times per shift | |

| Equivalent sound level at the driver's workplace (after the motor grader has worked 300 hours) dBA, no more | |

| Vibration Hygiene Standards and Vibration Performance Requirements |

according to GOST 12.1.012-90 |

|

Environmental indicators |

|

| Indicators meet the standards: | |

| GOST 12.1.005-88 |

the level of gas contamination at the driver's workplace |

| GOST 17.2.2.02-86, GOST 24028-80 |

exhaust smoke |

| GOST 17.2.2.05-86, GOST 24585-81 |

emissions of harmful substances with exhaust gases |

Video review of the DZ 98 motor grader

The DZ 98 motor grader is a special technique that is used for large-scale excavation and grading operations, in the construction and maintenance of roads on soils of 1-4 categories.

The manufacturer has provided various attachments in the configuration, significantly expanding the technological capabilities of the DZ-98 grader. On the rear hitch, you can install a ripper-scarifier, with which the driver of the motor grader loosens the soil. An additional wing can be installed on the grader blade, which allows the snow mass to be thrown onto the side of the road during snow removal. An optional side blade allows snow to be cleared behind fences.

All the main functions of the D3-98 motor grader are performed with the help of a special working body, which is a blade with a knife mounted on the machine frame and powered by a diesel engine. They can perform the functions of lowering, lifting, turning in a vertical and horizontal plane.

This motor grader has excellent maneuverability and a change in the angle of installation of the blade in planes, and the blade can also be taken out to the side.

In order to increase labor productivity and improve the working conditions of the operator in this technique, containing the main frame, balancers, automatic control system of the blade position, the working body and proportional sensors. In addition, an additional sensor is mounted on the second balancer.

The motor grader has a wide range of interchangeable working equipment (swivel dozer blade, side grader blade, rear ripper).

It is customary to start a review of technical data with the engine. The DZ-98 is equipped with the YaMZ-238NDZ, which is popular for Russian heavy equipment. It should be noted that the car is produced in two modifications, one of which is equipped with a Cummins engine. Both engines are diesel.

Total information motor grader DZ-98 |

|

| Motor grader class | |

| Width (with blade in transport position), mm | |

| Height (without flashing beacons), mm, no more | |

| Longitudinal base, mm | |

| Front wheel track of the grader, mm: | |

| Narrow | |

| broad | |

| Rear wheel track of the grader, mm: | |

| Narrow | |

| broad | |

| Ground clearance of the grader, mm: | |

| under the blade in transport position | |

| under the front axle | |

| under the rear axle | |

| under the suspension of the middle and rear axles | |

| Motor grader weight, kg: operational | |

| front axle | |

| attributable to the middle and rear axles | |

| Static ground load at operating weight, N (kgf): | |

| on a blade mounted perpendicular to the longitudinal axis | |

| on the scarifier's teeth | |

| The number of gears of the DZ-98 grader: | |

| when moving forward | |

| when moving back | |

| The speed of the motor grader at the rated speed of the engine crankshaft, km / h: | |

| when moving forward: | |

| I transfer | |

| 2nd gear | |

| III gear | |

| IV transfer | |

| V gear | |

| VI gear | |

| when moving backward: | |

| I transfer | |

| 2nd gear | |

| III gear | |

| IV transfer | |

| V gear | |

| VI gear | |

| Minimum turning radius when driving on dry concrete surface, m | |

| The slope of holding the grader with the parking brake,%, not less | |

| Braking distance of a motor grader moving at an initial speed of 30 km / h on a horizontal section of dry asphalt with the clutch disengaged, m, no more | |

| Braking distance of a motor grader moving at an initial speed of 30 km / h when braking by an emergency system (in case of failure of one of the circuits), m, no more | |

DZ-98 engine |

|

| Type of | diesel |

| Model | YaMZ-238NDZ Cummins M- 11C265 |

| Rated power, kW (hp) | 173 (240) 202 (275) |

| Rated speed, rpm | |

| Start | starter |

Transmission |

|

| Type of | mechanical, with all-wheel drive, with a front axle disengagement mechanism |

| Hydraulic pump drive reducer | single row with flexible coupling |

| Clutch | dry, two-disk, permanently closed with hydraulic maintenance of its drive, with a brake on the driven shaft |

| Transfer gear | single row for driving the middle and rear axles with parking brake |

| Parking brake | belt type |

| Intermediate gears to bridges | gimbals |

Chassis |

|

| Wheel formula | |

| Leading bridges | |

| Steering bridge | front |

| Main gear of bridges | single-stage, tapered, no differentials |

| Final drive axles | single-stage, cylindrical, with internal gearing |

| Half-shafts | fully unloaded type |

| Wheel brakes | multi-disc with sintered discs operating in an oil bath |

| Middle and rear axle suspension | balancer with reaction rods, providing pumping of bridges in the vertical plane |

| Front axle suspension | articulated, providing pumping of the bridge in the transverse plane |

| Tire size, inch | 16.00-24 or 20.5-25 |

| Tire pressure, MPa (kgf / cm2) | 0,23…0,28 (2,3…2,8) |

Work equipment (DZ-98 motor grader) |

|

|---|---|

Track paving |

|

| The volume of a prism drawing in a bulldozer position, m3, not less | |

| The width of the blade in the track position, mm, no more | |

| Blade height, mm, not less | |

| Main cutting angle when bulldozing blade position | |

| Blade angle back and forth from the bulldozer position in the plan, not less | |

Bulldozer |

|

| The volume of the drawing prism, m3, not less | |

| Blade width, mm, not less | |

| Blade height, mm, not less | |

| Lowering the blade below the support surface, mm, not less | |

| Blade main cutting angle | |

Loosening |

|

| Number of teeth of ripping equipment | |

| Maximum deepening of the ripper tooth equipment, mm, not less | |

| Capture width of ripping equipment, mm, not less | |

Grader blade |

|

| Blade length, mm, not less | |

| Blade height with knives, mm, not less | |

| Cutting angle | |

| The angle of cleaning the slopes at an angle of capture in the plane of the slope is not less than 45 ° | |

| Cuvette depth, m, not less | |

| inner wall slope | from 1: 2 to 1: 3 |

| outer wall slope | from 1: 1 to 1: 1.5 |

| Angle of installation in the horizontal plane, full-turn blade | |

| The angle of the part-turn blade from the position perpendicular to the longitudinal axis of the DZ-98 motor grader | |

| Side extension of the blade in both directions relative to traction frame, mm, not less | |

| Lowering the blade below the supporting surface, mm, not less | |

Additionally |

|

Control |

|

| Gearbox control, multiplier, reverse and front axle | mechanical |

| Clutch control | mechanical with hydraulic maintenance |

| Front wheel steering | hydraulic |

| Brake control: | |

| wheeled | pneumatic |

| parking | mechanical |

| Working bodies management | hydraulic |

Electrical equipment |

|

| Voltage, V | |

| Starter power, kW (hp) | |

| Rechargeable batteries: | |

| type of | |

| number | |

Filling tanks capacity |

|

| Fuel tank of the grader, l | |

| Engine cooling and heating system, l | |

| Engine lubrication system, l | |

| Hydraulic system of the grader, l | |

| Gearbox, hydraulic pump drive gearbox, transfer gearbox, l | |

| Main gear of rear, middle axles (each), l | |

| Main gear of the front axle, l | |

| Onboard axle reducer, l | |

| Wheel brake, l | |

| Anti-freeze fuse, l | |

| Blade rotation reducer, l | |

Technical and economic indicators |

|

| Hydraulic system working fluid consumption, g / engine hour, not more | |

| Specific fuel consumption, kg / m3, no more | |

Reliability indicators |

|

| 80% resource before the first overhaul, engine hours, not less | |

| Mean time between failures, engine hours, not less | |

| Technical utilization factor, not less | |

| Specific total operational labor intensity of periodic technical maintenance, e.h / motohour, not more | |

| Operational labor intensity of the shift technical service, person / hour, no more | |

Ergonomics indicators |

|

| Temperature at the driver's workplace, ° С: | |

| not less | |

| at a relative humidity of 40-60%, not higher | |

| at relative humidity 60-80%, not higher | |

| for areas with an average air temperature of 13 hours hot month, exceeding plus 25 ° С, not higher | |

| Efforts on the controls, N (kgf), no more: | |

| on the steering wheel when the DZ-98 motor grader moves at a speed of at least 8 km / h on a horizontal section with a dry, hard, even surface | |

| on the engine control pedal | |

| on the control levers of the implements used in each working cycle | |

| on the control levers of the machine used when moving it by its own motion | |

| on pedals like brake | |

| on levers and pedals used no more than five times per shift | |

| Equivalent sound level at the driver's workplace (after the motor grader has worked 300 hours) dBA, no more | |

| Vibration Hygiene Standards and Vibration Performance Requirements | according to GOST 12.1.012-90 |

Environmental indicators |

|

| Indicators meet the standards: | |

| GOST 12.1.005-88 | the level of gas contamination at the driver's workplace |

| GOST 17.2.2.02-86, GOST 24028-80 | exhaust smoke |

| GOST 17.2.2.05-86, GOST 24585-81 | emissions of harmful substances with exhaust gases |

Some technical and economic indicators

- DZ 98 fuel consumption - 0.15 kg / cu. m.

- Fuel tank capacity - 485 liters.

- The hydraulic system of the machine holds 120 liters of working fluid.

- Working resource in engine hours (minimum) - 8400.

- The coefficient of technical application is not less than 0.85.

- Labor intensity - 0.95 person / h.

- Ergonomics - 14-31 degrees, depending on climate conditions.

- Environmental standard - GOST 12.1.012-90.

- The emission of exhaust gases and the level of smoke in the workplace comply with the standards of GOST 17.2.2-02.86 and 17.2.2-05.86.

Engine

YaMZ-238, mainly used as a power unit, belongs to the Euro-1 ecological class and has a long service life. The motor power is 240 hp / 173 kW. The rated crankshaft speed is 1700 rpm. The engine is started by a starter.

Cummins M-11C265 has a power of 275 hp / 202 kW. Rated speed - 1700 rpm. Environmental class Euro-1. The motor is started with a starter. The specific fuel consumption of the DZ-98 motor grader in the minimum value is 220 g / kW * h (162 g / hp * h).

Gear box

The motor grader is equipped with a six-speed manual transmission (6 forward and 6 reverse), which is considered one of its advantages. The peculiarity of heavy equipment lies in the areas and areas of its application. In difficult conditions, a manual transmission is preferable, as it provides a certain margin of power and more opportunities for equipment. The maximum travel speed is 41 km / h forward and 47 km / h reverse.

The gearbox is equipped with four-wheel drive and is complemented by a front axle disengagement mechanism. The transmission system consists of:

- single-row hydraulic pump drive gearbox with elastic coupling;

- dry double-disc permanently closed clutch with hydraulic servicing of the drive and brake of the driven shaft;

- transfer case for driving the rear and middle axles with a hand brake;

- band-type handbrake;

- intermediate cardan drives to bridges.

Chassis and suspension

The DZ-98 motor grader is equipped with a 1x3x3 wheel arrangement and three driving axles. The front axle is steerable and obeys the steering mechanism. The main gear is single-stage bevel. There are no differentials in the design. Fully balanced axle shafts, sintered multi-disc oil-bath brakes, and single-stage cylindrical side axle reducers combine to deliver tremendous flotation and power to the entire chassis.

The suspension of the middle and rear axles is made with jet rods that provide vertical pumping of the axles. In contrast to this, the front axle has a hinge device that allows it to be pumped in the transverse plane. In this way, the machine gains stability even under heavy loads. The parking brake is capable of holding the vehicle at an angle of 15 degrees.

1- balancer; 2- bracket for attaching the balancer to the frame of the motor grader; 3- ball pin; 4- jet rod; 5- adjusting nut; 6- centering pin; 7- spacer bar; 8-stop; 9- cover of the ball bearing of the balancer; 10- adjusting shims; 11- stuffing box body; 12- axis of balancers; 13- balancer axle cover; 14- nut; 15- lock washer; 16 - thrust washer with a lock; 17- sleeve; 18 - fixed bushing; 19- sealant; 20 - washer; 21- conical spring; 22- gasket; 23- clip; 24- rear axle; 25- adjusting pin of the rear axle; 26- ball joint

Frame

Welded structure of head, main and rear pipe. A front axle, removable executive equipment, ball-type traction frame support are fixed on the head part. The pipe of the main part has brackets for attaching the cardan, which transfers rotation to the front axle. The cavities of the pipe part serve as a receiver for the brake air system. Two side members are attached to the rear of the frame device. Modular mounting on the frame of hinged devices is allowed. Equipment suspension mechanisms are of the same type in design.

Hydraulic system

Through the devices of the system, the executive bodies, clutch, movement and maneuvering of the grader are controlled. Gear pumps are installed in two circuits of the hydraulic system, hydraulic cylinders are used as actuators.

A hydraulic motor can be used in the blade swing mechanism.

1- hydraulic steering wheel; 2- hydraulic motor; 3 ~ hydraulic cylinder of additional working equipment; 4- hydraulic cylinder for pulling out the traction frame;

5- wheel steering cylinder; 6- hydrojunction; 7.22 - hydraulic cylinders for blade control; 9- filter; 10- servo mechanism; 11-pump NSh-71L; 12- pump NSh-50; 13.20 - pipelines; 14- breather; 15- valve; 16- hydraulic tank; 17- steering safety valve; 18- oil dipstick; 19- filler plug; 21- distributor; 23- blade extension hydraulic cylinder

Pneumatic system

A double-circuit device that provides a drive for the wheel brakes and the lever for the suspension of the traction frame equipment. The brake drive provides independent operating and emergency braking modes. Before starting the movement of the unit, compressed air is pumped into the receiver.

The pressure is controlled by a light alarm.

Equipment

A wide range of working equipment is provided for the DZ-98 motor grader. Track laying, bulldozing and ripping equipment is available to the customer, as well as a grader blade as standard. Aggregation takes place with a front or rear hydraulic linkage system.

The width of the blade with the track laying equipment is 3400 mm, the height is 950 mm. The cutting angle of the soil is 48 degrees. The volume of the drawing prism in the bulldozer position is 3 m3. Lowering the equipment below the supporting surface - at least 200 mm.

Dozer equipment has a blade width of at least 3200 mm. The volume of the drawing prism is 2.57 m3. The blade height is 970 mm. The main cutting angle is 55 degrees, the sinking below the supporting surface is at least 110 mm. The ripper for the DZ-98 grader has 5 teeth, a maximum depth of 230 mm and a width of 1800 mm.

Of greatest interest to buyers of DZ-98 is a grader blade. The length of the equipment is at least 4200 mm, the height with knives is at least 700 mm. The standard blade can work at an angle of 30 to 70 degrees. The angle of cleaning of slopes in standard conditions can reach 90 degrees. The blade extends laterally by at least 1050 mm relative to the side frame. The minimum lowering of the grader equipment below the supporting surface is 500

dimensions

In the basic modification, the DZ-98 grader has the following dimensions:

- length - 10800 mm;

- width (blade in transport position) - 3220 mm;

- cabin height without flashing beacons - 4000 mm;

- longitudinal base - 6000 mm.

Track (depending on the type of tires selected): front - 26222-2696 mm, rear - 2502-2576 mm. Ground clearance of the motor grader:

- 350 mm - under the blade in the transport position;

- 615 mm - under the front axle;

- 440 mm - under the rear axle;

- 395 mm - under the suspension of the rear and middle axles.

The operating weight of the grader is 19,500 kg. The mass is distributed in the following proportions:

- on the front axle - 5660 kg;

- on the rear and middle axles - 13 850 kg.

The machine creates a static load on the ground:

- blade in a position perpendicular to the axis - 103 kN (10500 kgf);

- on the scarifier teeth - 45.4 kN (4630 kgf).

The maximum turning radius is 18 m. The braking distance on the horizontal section with a residual motor grader speed of 30 km / h does not exceed 14 m, when braking by the emergency system - no more than 41 meters. The values were measured on a dry concrete surface.

Application

Due to its high power and productivity, the machine can work both in road and municipal construction, in irrigation and melioration systems. The equipment allows you to use the grader for loosening and excavating soil from the first to the fourth grade. The technique is actively used in the construction of airfields and for the production of expensive jobs of the highest complexity.

Advantages:

- Selection of a gearbox with a mode of operation through friction clutches.

- Optional installation of transmission hydromechanical units is possible.

- The all-wheel drive of the axles ensures the use of the machine on soft ground, high traction rates on the moldboard, maintaining direction when forming road ditches.

- The part-turn moldboard knife allows adjusting the traction force of the unit by adjusting the amount of material capture in width without changing the vertical cutting parameter. Due to this, the number of passes is reduced, the quality indicators of surface profiling increase.

- Multi-disc wheel brakes do not require adjustments, are durable and reliable.

- The steering column and operator's seat are adjustable for increased driving comfort.

Control

The motor grader is controlled from the all-metal cab. Control devices are located on a dashboard under the roof. The sprung seat and steering column are adjustable for the operator's height.

The cabin is equipped with ventilation and heating devices. All-round glazing and lights provide an adequate view of the grading area.

The gearbox is shifted by a lever, the front wheels and actuators are hydraulically controlled, the wheel brakes are pneumatically controlled.

Overview

The plant "Chelyabinsk Road Construction Machines" (ChSDM) has been producing graders of the DZ series since 1978.

The machines have gone through several stages of modernization. DZ-98 is the most powerful unit offered to road builders by RM-Terex JV, which includes the Chelyabinsk enterprise.

Purpose and features

DZ-98 is a unit designed for leveling the profile of the roadbed on soils with different densities. It is allowed to use in temperature parameters from plus 40 to minus 45 degrees Celsius.

The main functions are performed by a special grader's executive body - a moldboard knife fixed to the attachment of the unit. The tool is raised, lowered, rotated horizontally and vertically. Operated by the hydraulic system of the machine.

DZ-98 is effectively used in the production of:

- construction and repair work on roads of different categories;

- formation of the base of the road; movement of the removed rock in the embankment;

- formation and leveling of embankments;

- shifting materials along the roadway and mixing them;

- loosening of the rock and the removed roadbed residue (scarifying);

- profiling of areas of territories;

- snow removal works.

The operational parameters of the DZ-98 are as follows:

|

Index |

Unit rev. |

The quantity |

| Vehicle class | ||

| Dimensional parameters in width in height basic in length |

||

| Wheel track: narrow tires front wide tires front |

||

| Clearance bridges second third |

||

| Weight of the machine, ready for operation | ||

| Weight distribution of the first bridge | ||

| Weight distribution of the second, third bridges | ||

| Cargo impact on the soil blade blade scarifier |

||

| Movement rate | ||

| Power point | ||

| Fuel |

Diesel |

|

| Modification | ||

| Power parameters |

173 at 1,700 rpm 202 at 1,700 rpm |

|

| Electrical network and equipment | ||

| The value of the voltage in the network | ||

| Starter device, power parameter | ||

| Rechargeable battery power |

|

|

| Modification |

Power unit

The machine is equipped with four-stroke diesel engines, V-shaped, eight-cylinder YaMZ-8482, YaMZ-238NDZ, YaMZ-238ND2 and twelve-cylinder YaMZ-240G.

Some models are equipped with a U1D6-TK-S5 single-row six-cylinder unit of the Ural Motor Plant or a Cummins M-11C265 engine manufactured by the company of the same name from the USA.

Free access to the engine and systems is provided by the bonnet cover. The air cleaning device and exhaust suppression system are located in the space under the bonnet.

The basic configuration is equipped with a YaMZ-238ND2 diesel engine with direct fuel injection, equipped with a turbocharging system. The power unit uses 0.15 kg of fuel to process a cubic meter of rock with a grader.

Transmission

A mechanical device that transmits torque to three axles allows the cardan of the first axle to be disconnected.

The drive to the middle and rear axles is carried out through intermediate cardan shafts from a single-row-type distributing gear with a belt-type parking brake.

The gearbox, the clutch mechanism, the gear units of the hydraulic pump drive are combined in a single block and have a common lubrication system.

A gearbox with a multiplier mechanism provides 6 parameters of torque forward and backward.

The clutch is dry on two discs, has a hydraulic shut-off servo drive.

Unit frame

Welded structure of head, main and rear pipe. A front axle, removable executive equipment, ball-type traction frame support are fixed on the head part.

The pipe of the main part has brackets for attaching the cardan, which transfers rotation to the front axle. The cavities of the pipe part serve as a receiver for the brake air system. Two side members are attached to the rear of the frame device.

The pipe of the main part has brackets for attaching the cardan, which transfers rotation to the front axle. The cavities of the pipe part serve as a receiver for the brake air system. Two side members are attached to the rear of the frame device.

Modular mounting on the frame of hinged devices is allowed. Equipment suspension mechanisms are of the same type in design.

Running gear

Wheel formula - each axle is driven, the front one is steered.

Bevel final drive without differential mechanisms. Single-stage cylindrical final drives. In the onboard gear units of the second and third axles, a pneumatically controlled disc brake is provided.

For braking, the friction of cermet discs placed in a crankcase with oil is used.

In the balancing mechanism of the suspension of the 2nd and 3rd axles, steel rods are used, which synchronize the load between the frame and the chassis when moving (jet thrust). The first axle is hinged, the 2nd and 3rd axles are interchangeable.

Hydraulic system

Through the devices of the system, the executive bodies, clutch, movement and maneuvering of the grader are controlled. Gear pumps are installed in two circuits of the hydraulic system, hydraulic cylinders are used as actuators.

A hydraulic motor can be used in the blade swing mechanism.

Pneumatic system

A double-circuit device that provides a drive for the wheel brakes and the lever for the suspension of the traction frame equipment. The brake drive provides independent operating and emergency braking modes.

Before starting the movement of the unit, compressed air is pumped into the receiver. The pressure is controlled by a light alarm.

Control features

The motor grader is controlled from the all-metal cab. Control devices are located on a dashboard under the roof. The sprung seat and steering column are adjustable for the operator's height.

The cabin is equipped with ventilation and heating devices. All-round glazing and lights provide an adequate view of the grading area.

The gearbox is shifted by a lever, the front wheels and actuators are hydraulically controlled, the wheel brakes are pneumatically controlled.

Work and replacement equipment

The set of actuators includes:

- rotary bulldozer blade;

- grader blade, lateral;

- loosening device;

- scarifying device;

- devices for working with snow;

- track-laying mechanisms.

The technical characteristics of the attachments are as follows:

| Bulldozer type | ||

| Volumetric drawing parameter | ||

| Blade width | ||

| Blade height | ||

| Deepening the blade | ||

| Cutting with a mouldboard knife at an angle | ||

| Loosening type | ||

| Number of teeth | ||

| Teeth drift to depth | ||

| Capture width | ||

| Grader type | ||

| Length dimensions | ||

| Height dimensions | ||

| Bevel cutting | ||

| Slope cleaning at an angle | ||

| Deepening of the formed cuvette | ||

| Angle of full-turn moldboard | ||

| The angle of the quarter-turn moldboard to the machine axis | ||

| On-board extension of the dumping device | ||

| Deepening | ||

Benefits of Application

Options expanding the capabilities of the machine

- The LS hydraulic system regulates the operation of the hydraulic pumps according to the load, ensuring fuel economy.

- Manipulation of working bodies and maneuvering is carried out by joysticks.

- Main blade damper hydraulic system.

- Possibility of transition to the "floating" position of the blade.

- Powerful hydraulic steering pump and two-cylinder maneuvering control.

- Leveling by LEICA automation (2D and 3D).

- Satellite navigation device GLONASS.

- Equipping hinge devices with LINCOLN auto-lubrication units.

- Back scope camcorder.

- DYNOSET hydraulic tool canopy module.

- Work lighting on 4 sides.

- Heated fuel filter.

Features of the series

The CHSDM plant produces a line of DZ-98V motor graders. The subsequent digital index in the designation of the unit is determined by the model of the power plant:

The subsequent digital index determines the differences in the configuration from the base model and the availability of replacement equipment. So, DZ-98V1.1 is equipped with a scarifier, DZ-98V1.4 with bulldozer and loosening equipment, etc.

Service

You can study the equipment in more detail and purchase it with warranty support at one of the 70 branded sales centers operating under the brands of the Russian Machines corporation. The units are offered for direct sale, leasing, rent.

Price

June 2015 proposals for the cost of DZ-38 started at 3.2 million rubles. Prices for used cars fluctuate around 1.5 million rubles.

In conclusion, let's watch a short video about the DZ-98 grader:

The Chelyabinsk Machine-Building Plant has been producing road equipment of the DZ series since 1978. During this time, changes were made to the design several times. This is how the DZ-98 model was created, the technical characteristics of which indicate that it is the most powerful road equipment.

Purpose of technology

Grader DZ-98 is designed to form the profile of the site. It can be used on soils of different density. Differs in a wide range of operating temperatures: from -45 to + 40 ° C. There is a tropical option.

The DZ-98 motor grader is used:

- in construction;

- in repair work;

- for the formation of embankments;

- when preparing the foundation of the road;

- for profiling sites;

- when loosening rock and old coating;

- for cleaning snow and debris.

Main technical characteristics

The DZ-98 motor grader has the following technical characteristics:

| Indicator name | Meaning |

| Height (m) | 4 |

| Width (m) | 3,2 |

| Length (m) | 6 |

| Maximum ground clearance (cm) | 61,5 |

| Maximum travel speed | 47 km / h |

| R min turn | 18 meters |

| Braking distance at v = 30 km / h | 14 meters |

| With the circuit off | 41 meters |

| Blade angle | 0-360 ° |

| Blade lateral extension from | 102 cm |

| Moving the blade below the support surface | 50 cm |

| Number of forward gears | 6 |

| Number of reverse gears | 6 |

DZ-98 motor graders can be made in 6 versions, which differ in wheel width. Depending on this, some parameters differ:

Motor grader motor

The DZ-98 grader is powered by a YaMZ-238ND2 diesel engine with a turbocharging system for 8 cylinders, a YaMZ-240G for 12 cylinders, or Cummins. Both options are started with a starter. The crankshaft speed at which the maximum power is 1.7 thousand revolutions per minute.

The maximum power of the YaMZ-238NDZ engine is 170 kW. For Cummins M-11C265 - 202 kW.

Power transmission

The transmission unit is mechanical. It transmits rotation to the drive wheels. It is possible to disconnect from them, change direction and speed. Used to operate hydraulic pumps.

The power train assembly is connected to the flywheel of the motor. Crankshaft rotation is transmitted from the engine to the power train assembly through an elastic coupling.

The brake used for parking or holding on a slope is band. The clutch is dry, two-disc.

Chassis

The wheel formula of the DZ-98 motor grader is 1 * 3 * 3. In this case, all bridges are leading.

A feature of the DZ-98 motor graders: their middle and rear axles are interchangeable.

The axle shafts do not perceive the radial load from the wheels and are called unloaded. They can withstand significant loads.

To reduce the speed, a multi-disc wheel brake is used, the sintered discs of which are located inside the oil bath.

Suspensions of the middle and rear axles are balanced, with reaction rods. They provide vertical movement of bridges.

The front axle of the motor grader is driven and steered. This provides high traction on the blade, improved flotation.

Its design is similar to the previous ones, the attachment to the main frame and the parts that rotate the wheels are different.

Hydraulic system of the motor grader

The hydraulic system controls the clutch, side blade, maneuvering and movement of the motor grader.

The system consists of 2 circuits in which gear pumps are installed. Hydraulic cylinders are used as actuators. A hydraulic motor can be installed in the blade swivel mechanism.

Pneumatic system

The pneumatic system of the unit consists of two circuits. It allows you to control the wheel brakes and the suspension arm for the attached equipment. Service and emergency braking are independent of each other. An indicator light monitors the pressure inside the system.

Motor grader control process

Systems and mechanisms are controlled:

- mechanically- gearbox, parking brake, front axle, reverse, multiplier;

- mechanically with hydraulic maintenance- clutch;

- hydraulically- turning the front wheels, attachments;

- pneumatically- wheel brakes.

Unit actuators

The main working body of the motor grader is a blade with a knife, which is fixed to the traction frame. It has the ability to rotate vertically and horizontally, move up and down. The moldboard can be moved to the side.

Hinged track-laying mechanisms make the machine multifunctional. It:

- soil ripper;

- scarifying device for crushing dense soils and previous road surface;

- dozer blade;

- side grader blade.

In winter, a special wing is installed on the dump, which throws snow onto the side of the road. Using the optional side wing, skids can be cleared behind the guardrail. The frontal leaf at a low speed shifts the snow to the side, and at a high speed it scatters it by a dozen meters. As a result of such cleaning, a snow bank does not form along the road.

Bulldozer equipment is used for filling holes, making excavations. Soils of 1–2 categories are moved without preparation, 3–4 and frozen ones are preliminarily loosened.

The DZ-98 motor grader belongs to heavy motor graders, it has a class 250. This machine can rightfully be considered unique, because there are no analogues of the DZ 98 on the territory of Russia. The manufacturer of the DZ 98 motor graders is the UUMK company, which is located in Chelyabinsk. Modifications and the device of DZ 98 make it possible to use it for the construction of the roadway, as well as for its subsequent maintenance. This unit is also capable of developing soils of 1-4 categories. It should also be noted that DZ 98 can be used without problems in the construction of facilities such as railways, irrigation, land reclamation, airfields.

The main structure of this model includes a grader and bulldozer blades, a ripper, but most of all, it is a grader-type blade that is installed directly on the machine frame for work. It should be noted that, for all its dimensions, the DZ 98 has good maneuverability. In addition, the manufacturers of this machine have taken care of the comfort of the driver, whose cab is equipped with the best equipment. It is most advisable to use such a machine when it is necessary to perform a large amount of work.

Erection of embankments, planning, snow removal, grading, construction of troughs, mixing of soils, transportation of materials - this is not a complete list of the possibilities of the DZ 98 motor grader. The real machine is produced in two versions (for a normal climate and for a tropical one). The price for DZ 98 reaches five and a half million rubles.

Technical characteristics of the DZ-98 motor grader

| Total information | |

| Class | 250 |

| Weight, operational | 19 500/20 487 kg |

| Dimensions (LxWxH), mm | 10800x3220x4000 |

| Narrow front wheel track | 2622 mm |

| Wide front wheel track | 2 696 mm |

| Narrow rear wheel track | 2 502 mm |

| Wide rear wheel track | 2,576 mm |

| Front axle weight of the grader | 5 660 mm |

| Middle and rear axle weight | 13 850 mm |

| Ground load with blade mounted perpendicular to the longitudinal axis | 103,000 N (10,500 kgf) |

| Ground load on scarifier teeth | 45 400 N (4 630 kgf) |

| Number of gears | 6 forward / 6 reverse |

| Pull on blade when moving forward | 185 650 N (18 565 kgf) |

| type of drive | 1x3x3 |

| Minimum turning radius | 18 m |

| Parking brake holding slope | not less than 15% |

| Leading bridges | all (3) |

| Steering bridge | front |

| Half-shafts | fully unloaded type |

| Tire size | 16.00-24 inch or 20.5-25 inch |

| Tire pressure | 0.23 .... 0.28 MPa |

| Engine | |

| Type of | diesel |

| Model | YaMZ-238NDZ or Cummins M-11C265 |

| Power | 173 kW (240 PS) or 202 kW (275 PS) |

| Rotation frequency | 1700 rpm or 1700 rpm |

| Start | starter |

| Min. specific fuel consumption | 220 g / kWh (162 g / hp h) |

| Transmission type | mechanical, with all-wheel drive, with a front axle disengagement mechanism |

| Parking brake | belt type |

| Intermediate gears to bridges | gimbals |

| The speed of the machine forward at number. knee rotation speed. shaft | from 3.5 to 41 km / h |

| Grader blade | |

| Length | 4 200 mm |

| Height | 700 mm |

| Cutting angle | 30-70 |

| not less than 500 mm | |

| Dozer blade | |

| Width | 3 200 mm |

| Blade height | not less than 970 mm |

| Drawing prism volume | 2.57 m 3 |

| Lowering the blade below the support surface | 110 mm |

| Main cutting angle | 55 |

| Ripper | |

| Number of teeth | 5 |

| Ripper width | 1 800 mm |

| Maximum ripper depth | 230 mm |

Video

|

This article contains information about one of the most popular modifications of the DZ 98 motor grader. You can find out not only those. machine data, but also its detailed description. |

|

Not so long ago, the Oryol Road Machinery Plant produced models DZ 122 and DZ 122-1, as well as their modifications, after which a modernized motor grader DZ 122A was created on their basis. |

|