Tightening torques of the ZMZ 405 engine. Re-broaching the cylinder head

Hello again :) However, I am often asked, “do I need re-broaching cylinder head? " There are many who believe that they put the head on, tightened it and do not touch it anymore.

In the process of my rather long work as a minder, and this is already more than a quarter of a century, I was convinced from my own experience that if you are too lazy to stretch the head through the time set for pulling it, then after a while, and this largely depends on the driving style driver and distance traveled at the same time, you will have to shoot.

Usually the gasket burns out within a year, and if a person travels a long distance, then in a month. Therefore, my advice is this: you cannot go far with the head not extended, otherwise you will have to take it off on the road. But you know, I noticed that if the equipment came directly from the factory, then after the mileage set for broaching, the heads rarely weaken. It is possible that the material of the gasket that is put there is different.

So how long does it take to pull the cylinder head? On average, after a thousand km. mileage. This is written in the instructions and this is confirmed by practice. In the instructions for so. it is also written that after ten thousand it is necessary to stretch again or check the broaching of the head.

Well, in most cases, one broach was enough. But rarely, of course, but there were cases that when the gasket burned out, the head was weak even after one broach. In my opinion it all depends on the material cylinder head gaskets Which shrinks strongly, and which does not sag at all.

The physics of this phenomenon, namely the weakening of the head broach, is obvious. Usually, the cylinder heads are aluminum, and the bolts or studs are still steel. When aluminum is heated, the expansion coefficient is greater than that of steel, and when the engine heats up, the head expands and squeezes the gasket like a press, and when it cools down, it also releases the gasket, and the bolts are esessno loosened.

There is a rule: you cannot stretch hot engine, only cold. I will tell you a list of engines that you need to stretch from my experience with which I dealt, namely: zmz405,406,409. engines Zmz-402, UAZ 417.421. Engines zmz 511,512,523, zil-130, Ural.

I will not say about others, but usually VAZ heads rarely sink. I can’t say anything about foreign cars either, because I didn’t go through a lot of them, and I don’t want to f *** in vain. That's all for now.

So what is our conclusion? But to what! stretch out the heads in time! And then the gaskets will burn to hujam!

There is more to come. In order not to suffer with the repeated broaching of the head, you have to disassemble almost half of the engine, in order to make sure that it does not weaken, but otherwise it happens. Depends on the gasket material. You can't guess right away.

In order not to re-stretch the heads, you can put a metal package. You can read about that. And although I wrote about the UAZ-patriot, this may apply to many engines. Good luck friends!

Install the connecting rod cover. The numbers stamped on the connecting rod cover and the lower connecting rod head must match and be on the same side.In the same way, we install the remaining pistons into the cylinder block. Tighten the connecting rod cap bolt nuts to a torque of 68-75 Nm.

We turn the crankshaft by the flywheel. The movement should be smooth, but the resistance to rotation will increase (compared to rotation crankshaft without connecting rods).

Installing the oil pump with a new gasket ...

And we wrap the bolts of its fastening (tightening torque 25-40 Nm).

We wrap the bolt of the oil pump bracket with a torque of 7-10 Nm.

Turning the crankshaft, set the crankshaft sprocket mark opposite the cylinder block alignment mark.

Assembling the oil pump drive

(see "Dismantling the oil pump drive"), covering engine oil drive gears, intermediate shaft bushings and the shaft itself. Installing the lower chain damper Before installing, dip both chains in engine oil.

ATTENTION

When installing the sprocket of the lower chain tensioner, make sure that the marks on the sprockets of the crankshaft and countershaft coincide with the corresponding marks on the cylinder block (see "Dismantling the timing mechanism").

We change the seal in the front cover of the cylinder block (see "Replacing the front crankshaft oil seal") and install the cover with a new gasket and generator bracket.

Install the lower chain hydraulic tensioner (see "Removing and installing hydraulic tensioners").

We tighten and tie the upper timing chain to the generator bracket. We apply silicone sealant to the cylinder block mating plane (for attaching the oil pan), to the joints of the front and rear covers with the cylinder block.

Install the oil pan (tightening torque of the oil pan mounting bolts 12-18 Nm, and the nuts 11-16 Nm).

Install the clutch crankcase amplifier. We put a pulley on the toe of the crankshaft and tighten the ratchet bolt to a torque of 104-128 Nm.

Install the cylinder head (see "Removing and repairing the cylinder head").

Install discs and clutch housing (see "Replacing the driven and driving discs").

Install the starter (see "Removing the starter").

We install the coolant pump (see "Replacing the coolant pump"), the generator (see "Removing the generator"), the tensioner roller with the tensioner (see "Replacing the tensioner roller of the accessory drive belt"). *

Further assembly of the ZMZ 406 engine is carried out in the reverse sequence to disassembly.

Page 2 of 2

12. Bend the holder of the accelerator cable and remove the cable from it. Move the accelerator cable away from the engine.

Disconnect the wires from the generator.

13. Disconnect the connector 1 from the controller. idle move... Unscrew nut 2 and remove the "earth" wires from the stud at the rear end of the receiver.

14. Disconnect connector 1 from air temperature sensor.

Loosen the clamp 2 and remove the coolant supply hose from the heater tap

15. Disconnect plug strips 1 from injectors. Unbend holders 2 of the wiring harness and remove the harness from the holders.

Move wiring harness away from engine.

Then disconnect the front exhaust pipe from the exhaust manifold, disconnect the hose from the body throttle, remove the radiator inlet pipe, remove the generator.

1. Remove the camshafts.

2. Loosen the tightening of the clamps 1 and remove the hoses 2 and 3 from the throttle body fittings.

3. Remove the thermostat with the housing.

4. Remove the spark plugs.

5. Remove the bolts 1 securing the block head. Remove bolts 1 and washers.

6. Remove the cylinder head and head gasket.

Do not drive screwdrivers or any other tool between the cylinder head and the cylinder block, as this could damage the surface of the cylinder head adjacent to the cylinder block.

Installation

Install the block head in the reverse order of removal.

The order of tightening the bolts securing the head of the block is shown in the figure.

Tighten the bolts of the block head in two stages:

1st stage - 40-60 N · m (4.0-6.0 kgf · m);

2nd stage - 130-145 N · m (13.0-14.5 kgf · m).

:Pre-tightening;

Exposure not less than 1 min 15 sec;

Rotation at an angle of 90

Bolts of fastening of a head of cylinders to a cover of a chain

Cover bolts camshafts

Crankshaft pinch bolt

170-220 (17,0-22,0)

Camshaft sprocket retaining bolts

Intermediate shaft sprocket retaining bolts

2. Other connections:

Crankshaft dirt trap plugs

Seal holder retaining bolts

Lower chain guide bolts

Middle and upper chain guide bolts

Chain Tensioner Support Bolts

Chain Tensioner Lever Bolts

Hydraulic tensioner cover bolts

Front and rear cylinder head covers retaining bolts

Oil pan retaining bolts

Oil pan retaining nuts

Clutch Booster Bolts

Union oil filter

Oil pump drive cover bolts

Designation in JSC "ZMZ"

|

Connection name |

Number of connections |

Tightening torque, Nm (kgfm) |

|

Screws for fastening the thermostat housing to the cylinder head |

|

|

|

Screws and nuts for securing chain cover and water pump |

|

|

|

Bolt of fastening of the water pump to the chain cover |

||

|

Exhaust manifold retaining nuts |

||

|

Intake pipe retaining nuts |

||

|

Receiver mounting nuts |

||

|

Valve cover retaining bolts |

||

|

Automatic accessory drive belt tensioner retaining screw |

||

|

Cooling hose clamps |

3,9-6,0 (0,39-0,6) |

|

|

Clutch housing retaining bolts |

||

|

Clutch fork support bolt |

||

|

Starter mounting bolts |

||

|

Nuts for fastening the generator to the upper and lower brackets |

||

|

Pulley retaining nut on the generator shaft |

||

|

Spark plug |

||

|

Ignition coil retaining nuts |

||

|

Knock sensor retaining nut |

20 0.5 (2.0 0.05) |

|

|

Coolant temperature sensor |

||

|

Oil pressure warning switch |

||

|

Throttle mounting screws |

||

|

Fuel line retaining screws with injectors |

||

|

Timing sensor bolt |

||

|

Phase sensor bolt |

||

|

Parts not listed with tapered threads: |

||

|

Connection name |

Number of connections |

Tightening torque, Nm (kgfm) |

Appendix 3

Rolling bearings used in the ZMZ-40524 engine

|

Bearing name |

Designation |

Quantity, pcs. |

|

Sock input shaft transmission (in the flywheel): |

||

|

Single row deep groove ball with two shields or |

402.1701031 (6203ZZ.P6Q6 / US9) |

|

|

Single row deep groove ball with double-sided sealing |

402.1701031-01 (6203.2RS.P6Q6 / US9) or 402.1701031-02 (6203.2RS2.P63Q6 / U.C30) |

|

|

Tensioner lever with sprocket assembly with bearing |

||

|

Automatic tensioning mechanism for the drive belt of the units assembled with a roller with a bearing |

Engine cuffs

Appendix 4

|

Name |

Designation |

Quantity, pcs. |

|

Front crankshaft seal |

f. "Rubena", Czech Republic |

|

|

Rear crankshaft seal |

406.1005160-03, JSC VELKONT, Kirovo-Chepetsk or 2108-1005160, JSC "Balakovorezinotekhnika", Balakovo or 4062.1005160 * (546.941), f. "Elring", Germany or 4062.1005160-01 * (03055VOOA), f. "Rubena", Czech Republic |

|

|

Water pump seal |

40522.1307020 * (94412) f. "MTU", Italy |

|

Oil deflector cap, intake and exhaust valves, assy |

406.1007026-03 * (648.32G) f. "Rubena", or 406.1007026-04 * (2108-1007026-02), OJSC "VELKONT", Kirovo-Chepetsk |

|

|

Crankshaft toe seal ring |

406.1005044* (038-044-36-2-2 GOST 18829-79) |

Appendix 5

Unbalance of rotating parts allowed when assembling the engine

|

|

Balancing method |

Permissible imbalance, g cm, no more |

How to eliminate the imbalance |

|

Crankshaft |

Dynamic |

in planes passing through the extreme radical necks |

Drilling holes ¯ 14 mm to a depth of no more than 25 mm in the radial direction from counterweights. The intersection of the holes and the exit on the surface of the ends of the counterweights is not allowed |

|

Rice. 3.6. Crankshaft balancing: - the base for installing the crankshaft on the machine; - clamp |

|||

|

Pulley - crankshaft damper |

Static |

Drilling holes ¯ 10 mm to a depth of no more than 12 mm, taking into account the cone of the drill in the damper disc in the radial direction at a distance of 10.5 mm from the rear plane. The distance between the axes of the holes is not less than 18 mm |

|

|

Rice. 3.7. Balancing the damper pulley: 1 - pulley damper; 2 - mandrel; 3 Static balancing device |

|||

|

Flywheel with rim |

Static |

Drilling holes Ø 14 mm to a depth of no more than 12 mm, taking into account the cone of the drill on the side opposite to the clutch attachment at a radius of 115 mm. Drill no more than 10 holes. Distance between axles not less than 18 mm |

|

|

Rice. 3.8. Flywheel balancing: 1 - flywheel; 2 - mandrel; 3 - device for static balancing |

|||

|

Clutch pressure plate assy |

Static |

50 - when checking 15 - when balancing |

Installation of balancing weights in the holes of the casing flange or drilling in the casing flange with a diameter of 273 holes Ø 9 mm between the holes for the weights |

|

Clutch disc assy |

Static |

30 - when checking 15 - when balancing |

Installation of balancing weights |

Appendix 6

Tools and accessories for engine repair Tools developed by JSC "ZMZ"

|

Designation |

Name |

|

Puller pulley-crankshaft damper |

|

|

Tool for pressing the gear and hub onto the crankshaft |

|

|

Crankshaft sprocket and bushing puller |

|

|

Crankshaft sprocket pressing tool |

|

|

Mandrel for pressing in oil seals |

|

|

Device for drying and drying valves |

|

|

Removal and installation pliers piston ringsØ 95.5 mm |

|

|

Mandrel for compression of piston rings Ø 95.5 mm |

|

|

Oil filter wrench |

|

|

Clutch disc centering tool |

|

|

Mandrel for pressing on valve stem seals |

The tool developed by JSC "GAZ"

|

Designation |

Name |

|

Tool for removing and installing the crankshaft damper pulley and removing the crankshaft sprocket |

|

|

Set of mandrels for pressing on valve stem seals |

|

|

Oil filter wrench |

|

|

Adapter for special tool 6999-7697 for installing a crankshaft damper pulley |

|

|

Tool for removing the bearing of the front end of the gearbox shaft from the flywheel |

|

|

Gearbox shaft front end bearing remover from flywheel (together with tool 6999-7810) |

|

|

Clamp for compression of the valve spring |

|

|

Adapter for clamp 6999-7931 for compression of the valve spring |

|

Designation |

Name |

|

Oil filter remover |

Appendix 7

Engine fluids

|

Brand name and designation |

Change frequency |

Volume refilled into the product |

Note |

|||

|

The main |

Duplicate |

Foreign |

Main brand |

Duplicating Aya mark |

||

|

Fuel: |

Unleaded gasoline 91 ... 93 RON (RON - research octane) |

|||||

|

"Regular Euro-92" GOST R 51866 |

"Premium Euro 95" or "Super Euro-98" GOST R 51866 |

|||||

|

Motor oil according to STO AAI 003: |

Motor oil according to SAE J 300, API 2 : |

Dry engine excluding radiator filling volume |

Application temperature range: |

|||

|

SAE 0W-30, API SL |

from minus 30 ° С to plus 20 С |

|||||

|

SAE 0W-40, API SL |

from minus 30 ° С to plus 25 С |

|||||

|

SAE 5W-30, API SL |

from minus 25 ° С to plus 20 С |

|||||

|

SAE 5W-40, API SL |

from minus 25 ° С to plus 35 С | |||||

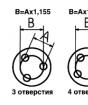

Diagram of installation and stamping of camshaft covers

I - front cover;

II - intake valve shaft;

III - exhaust valve shaft.

SEQUENCING

We remove the tips from the spark plugs along with the high-voltage wires.

Remove the ignition coils (see Checking and replacing the ignition coils). The coils can be left on the cover by disconnecting the low voltage wires from them.

Disconnect the throttle and air valve drive cables from the carburetor (see Removing the carburetor).

Remove the grille and upper grille panel (see Removing the grille grille and Removing the upper grille panel).

We disconnect the wires from the oil temperature and pressure sensors (see Replacing the temperature gauge sensors, Replacing the oil pressure sensors), bend the wire fastening brackets ...

… And remove the wires from the engine.

We loosen the clamp and disconnect the small hose of the crankcase ventilation system.

Using the "12" wrench, unscrew the eight bolts of the block head cover.

Remove the cover.

Turning the crankshaft with the head "36", we set it to the TDC position of the compression stroke of the first cylinder, (the risk on the crankshaft pulley must coincide with the protrusion on the front cover of the cylinder block, ...

... and the marks on the camshaft sprockets must be turned in opposite directions and be in line with the upper edge of the cylinder head.

ATTENTION

Do not turn the crankshaft during further work.

For convenience, we remove fuel pump(see Removing the fuel pump of the ZMZ-4063 engine) and, without disconnecting the hoses, take it to the side (you can leave the fuel pump on the cover).

Using the 12 key, unscrew the four bolts (the two lower ones are short).

Remove the front cover of the cylinder head ...

And a gasket.

Using a 6-point hex wrench, unscrew the two screws ...

… And remove the upper damper of the upper chain.

With the same key, unscrew the two screws securing the middle damper.

We loosen the chain tension in the area near the middle damper by turning the exhaust valve shaft clockwise with a "17" wrench for the sprocket mounting bolt (or with a "30" wrench for a square on the shaft).

We remove the middle soot.

Holding the exhaust valve shaft with a "30" wrench, unscrew the sprocket mounting bolt with a "17" wrench.

Remove the sprocket from the exhaust valve shaft.

Similarly, we unscrew the bolt securing the intake valve shaft sprocket.

Remove the eccentric of the fuel pump drive ...

… And an intake sprocket.

Using the "12" head, unscrew the four bolts securing the front camshaft cover.

Removing the front cover ...

... and plastic inserts for limiting the axial movement of the camshafts.

Using the "12" head sequentially, half a turn, loosen the tightening of the cap fastening bolts camshaft until the valve springs stop pressing the shafts.

Finally, we unscrew the bolts and remove the covers.

We remove the camshaft.

Remove the second camshaft in the same way.

Before installing the camshafts, lubricate their bearing journals, cams, as well as beds in the head and covers with engine oil.

Install the exhaust valve shaft with the pin to the right (looking from the front), and the intake valve shaft with the pin up. In this case, the shafts are in a stable position (for clarity, the radiator hose has been removed).

The intake and exhaust camshafts are interchangeable, but ...

ATTENTION

Pay attention to the correct position of the pins in the holes in the camshaft flanges.

We install each cover in its place, according to the serial number stamped on it.

We orient the caps so that the number embossed on them is facing the outside of the head.

We tighten the cover fastening bolts with a torque of 1.9-2.3 kgf.m, after which ...

… We turn the intake valve shaft so that its pin is opposite the upper edge of the block head.

We install sprockets with a chain on the shafts, starting from the exhaust camshaft.

With a tensioned branch of the chain on the side of the middle damper, the mark on the sprocket should be located opposite the upper edge of the block head.

We put the middle damper in place and put the second asterisk.

We carry out further assembly in the reverse order of disassembly.

ATTENTION

After installing the hydraulic tensioner ...

We check the coincidence of all marks on the crankshaft pulley and sprockets. Otherwise, remove the incorrectly installed sprocket and, by moving it to one section of the chain, reinstall it.